Post-surgery functional barrier film and method for preparing the same

A barrier film and functional technology, applied in the field of biodegradable polymer anti-adhesion film, can solve the problems of reducing interstitial fluid penetration, tissue healing, inability to achieve time-release of various drugs, and unsatisfactory anti-adhesion effects, etc. Achieve the effect of preventing peridural fibrosis and adhesion, reducing interstitial fluid penetration, and reducing organ infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 10 grams of poly D with a molecular weight of 400,000, L-lactic acid and 0.2 grams of cortisone into 100 ml of ethyl acetate, fully dissolve and mix well, then pour it into a flat container to form a film, and make the ethyl acetate fully volatilize to form a thick film. It is a 0.04 mm film, cut into 4×6 (mm), 10×20 (mm) and 50×80 (mm) sheets, and after disinfection and sterilization, it is vacuum-sealed and protected from light for future use.

Embodiment 2

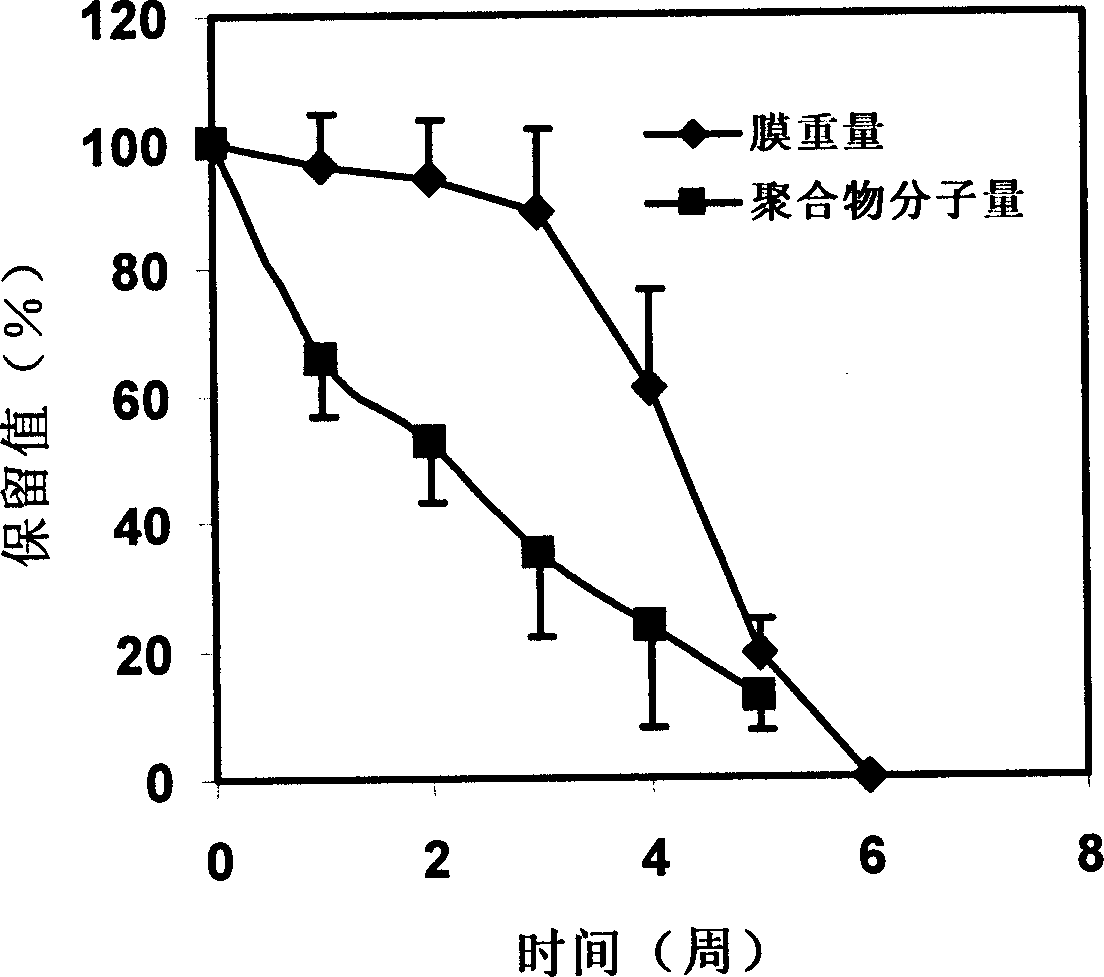

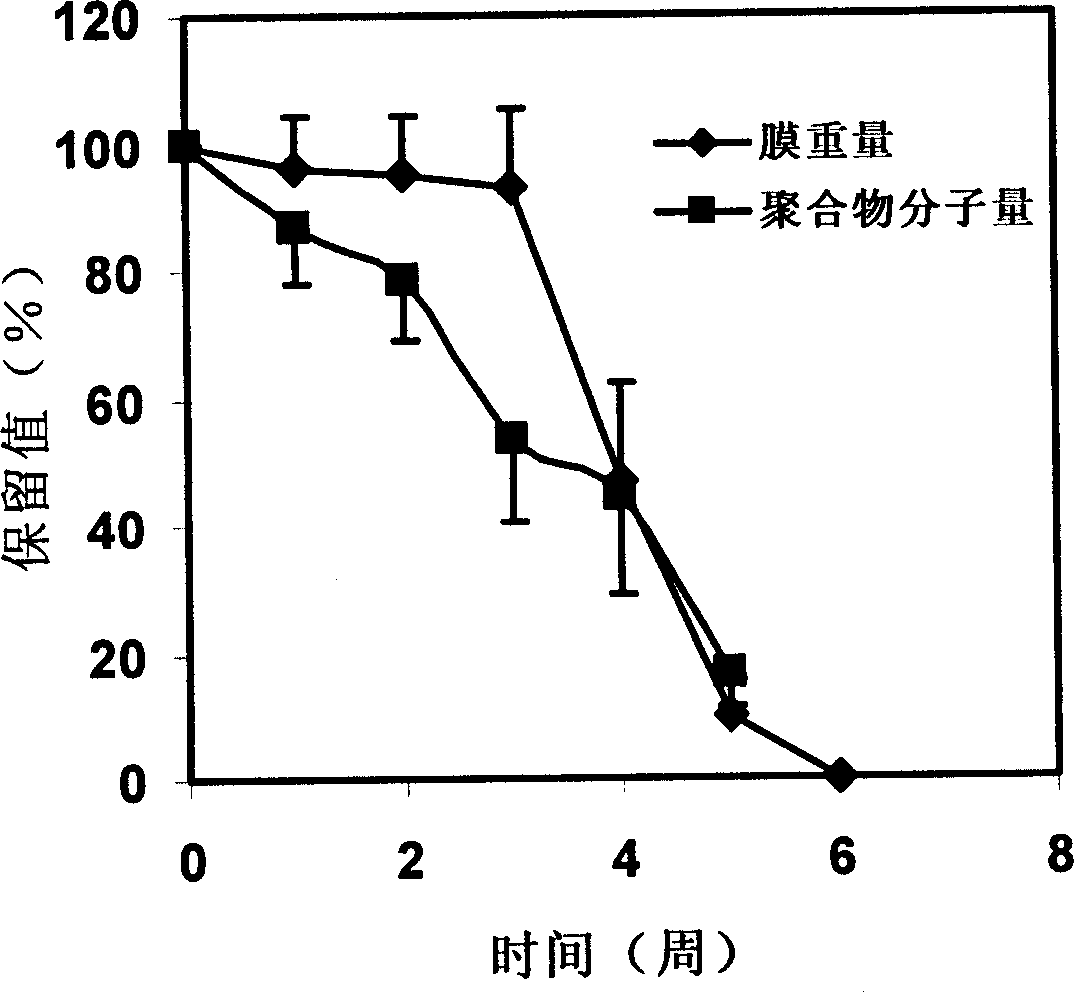

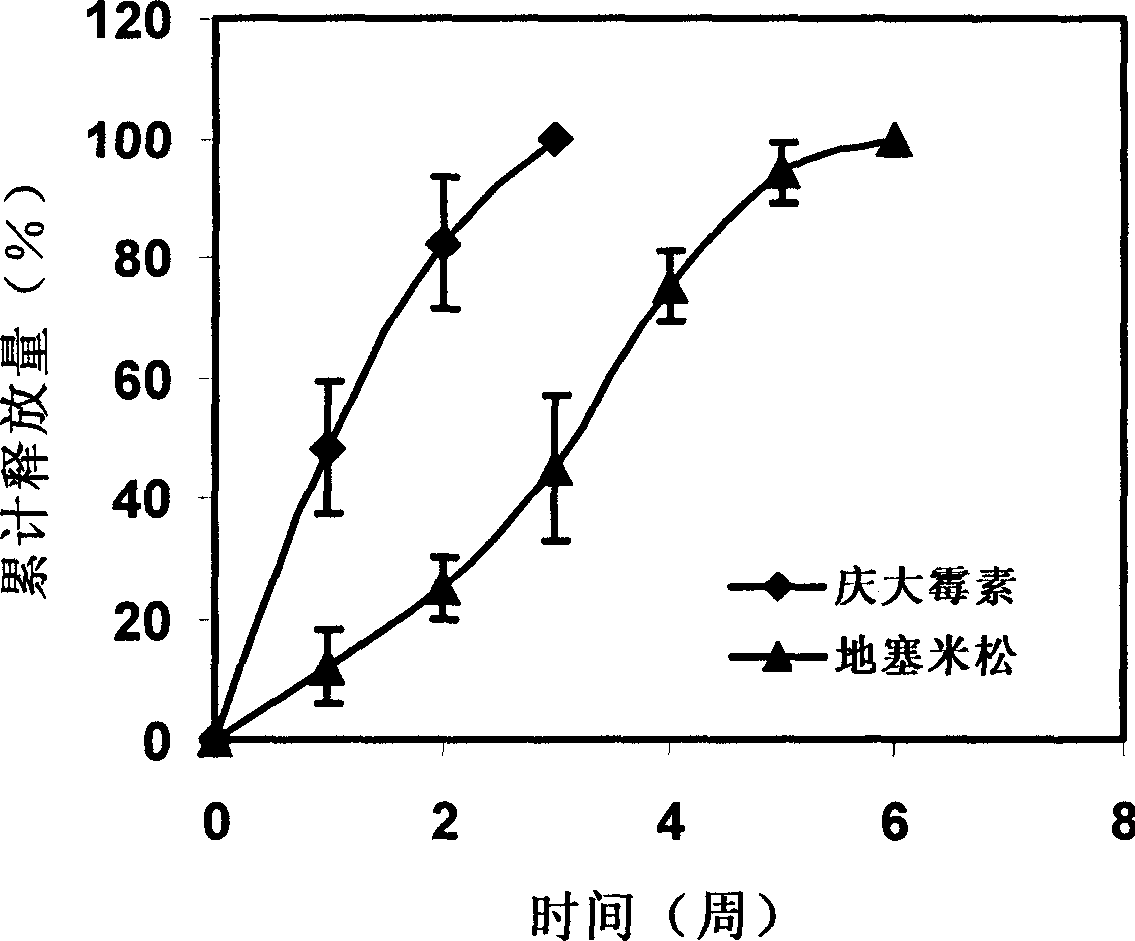

[0024] Take 10 grams of D, L-lactic acid, glycolic acid and caprolactone copolymer with a molecular weight of 150,000 and add it to 100 ml of acetone. After fully dissolving, add 0.15 g of gentamicin and 0.15 g of dexamethasone, mix well, and pour into Form a film in a flat container, make acetone fully volatilize to make a film with a thickness of 0.08 mm, cut into 4×6 (mm), 10×20 (mm) and 50×80 (mm) sheets, and disinfect and sterilize After processing, vacuum seal and store away from light for later use.

Embodiment 3

[0026]Take 5 grams of poly D with a molecular weight of 350,000, add 50 ml of ethyl acetate to L-lactic acid, add 0.15 g of hydrocortisone after fully dissolving, mix well, pour it into a flat container to form a film, and make the ethyl acetate fully volatilize An upper layer film having a thickness of 0.03 mm was prepared. Take 3 grams of D, L-lactic acid and glycolic acid copolymer with a molecular weight of 150,000, add 50 milliliters of ethyl acetate, add 0.15 grams of nifedipine after fully dissolving, mix well, pour it into a flat container to form a film, and make ethyl acetate The ester is fully volatilized to form a middle layer film with a thickness of 0.02 mm. Take 2 grams of poly D with a molecular weight of 50,000, L-lactic acid and polyethylene glycol copolymer and add it to 20 milliliters of acetone. After fully dissolving, add 0.15 grams of kanamycin, mix well, and pour it into a flat container to form a film. The acetone is fully volatilized to form a bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com