Method for producing organic acid ammonium salt solution

A technology of ammonium organic acid and organic acid, applied in fermentation and other directions, can solve the problem of few evaluation of neutralizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Embodiment 1 adopts the salt exchange of ammonia

[0096] (1) Preparation of magnesium succinate solution (magnesium succinate concentration 12.3% by weight, 30kg)

[0097] 25.35 kg of distilled water was added to a 100 L stirred vessel and stirred with an anchor blade at 30 rpm. The stirring vessel was controlled to normal temperature by passing water through the interlayer. A suspension was prepared by adding 1.54 kg of magnesium hydroxide (Wako Pure Chemical Industries, Ltd.) to the stirring tank. While monitoring the temperature of the suspension, 3.12 kg of succinic acid (Wako Pure Chemical Industries, Ltd.) was gradually added to the suspension. The neutralization reaction provided 30 kg of an aqueous solution of magnesium succinate.

[0098] (2) Salt exchange reaction using ammonia

[0099]After the above operation, 25% ammonia water (Wako Pure Chemical Industries, Ltd.) was mixed into the magnesium succinate aqueous solution (30 kg) for salt exchange. The m...

Embodiment 2

[0113] Embodiment 2 adopts the salt exchange of ammonium carbonate

[0114] (1) Synthesis of magnesium succinate solution (magnesium succinate concentration 12.3%, 10kg)

[0115] 8.45 kg of distilled water was added to a 15 L stirred vessel and stirred with a paddle blade at 200 rpm. The stirring container was controlled at normal temperature by passing water through the interlayer. A suspension was prepared by adding 0.51 kg of magnesium hydroxide (Wako Pure Chemical Industries, Ltd.) to the stirring tank. While monitoring the temperature of the suspension, 1.04 kg of succinic acid (Wako Pure Chemical Industries, Ltd.) was gradually added to the suspension. This neutralization reaction provided 10 kg of an aqueous solution of magnesium succinate.

[0116] (2) Salt exchange reaction using ammonium carbonate

[0117] After the above operation, ammonium carbonate (Wako Pure Chemical Industries, Ltd.) was mixed into the magnesium succinate aqueous solution (10 kg) for salt ex...

Embodiment 3

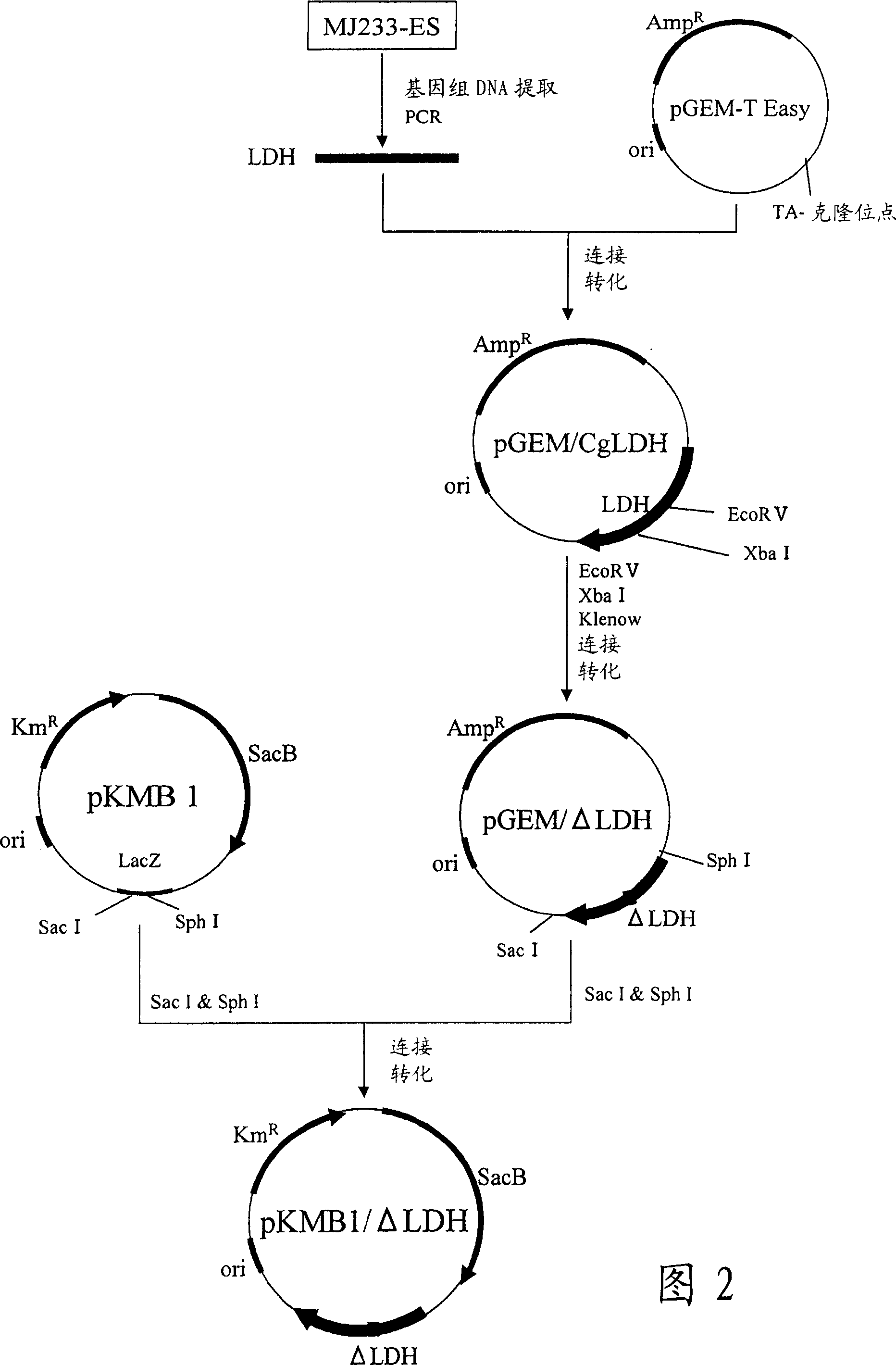

[0133] Embodiment 3 utilizes fermentation to carry out the preparation of magnesium succinate solution and the preparation of double salt

[0134] (1) Preparation of bacterial cells

[0135] Add 100 mL of culture medium into a 500 mL Erlenmeyer flask, and heat the culture medium at 120°C for 20 minutes to sterilize, then cool to room temperature. The culture medium contains 4 g of urea, 14 g of ammonium sulfate, 0.5 g of diphosphate Potassium hydrogen, 0.5g dipotassium hydrogenphosphate, 0.5g magnesium sulfate heptahydrate, 20mg ferrous sulfate heptahydrate, 20mg manganese sulfate hydrate, 200μg D-biotin, 200μg thiamine chloride, 1g yeast extract and 1g casamino acids. Then, 4 mL of pre-sterilized 50% glucose aqueous solution and 50 μL of filter-sterilized 5% kanamycin solution were added thereto. The Brevibacterium flavum MJ233 / FRD / PC / ΔLDH strain constructed in the following Reference Example was inoculated therein, and seed culture was performed at 30° C. for 24 hours. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com