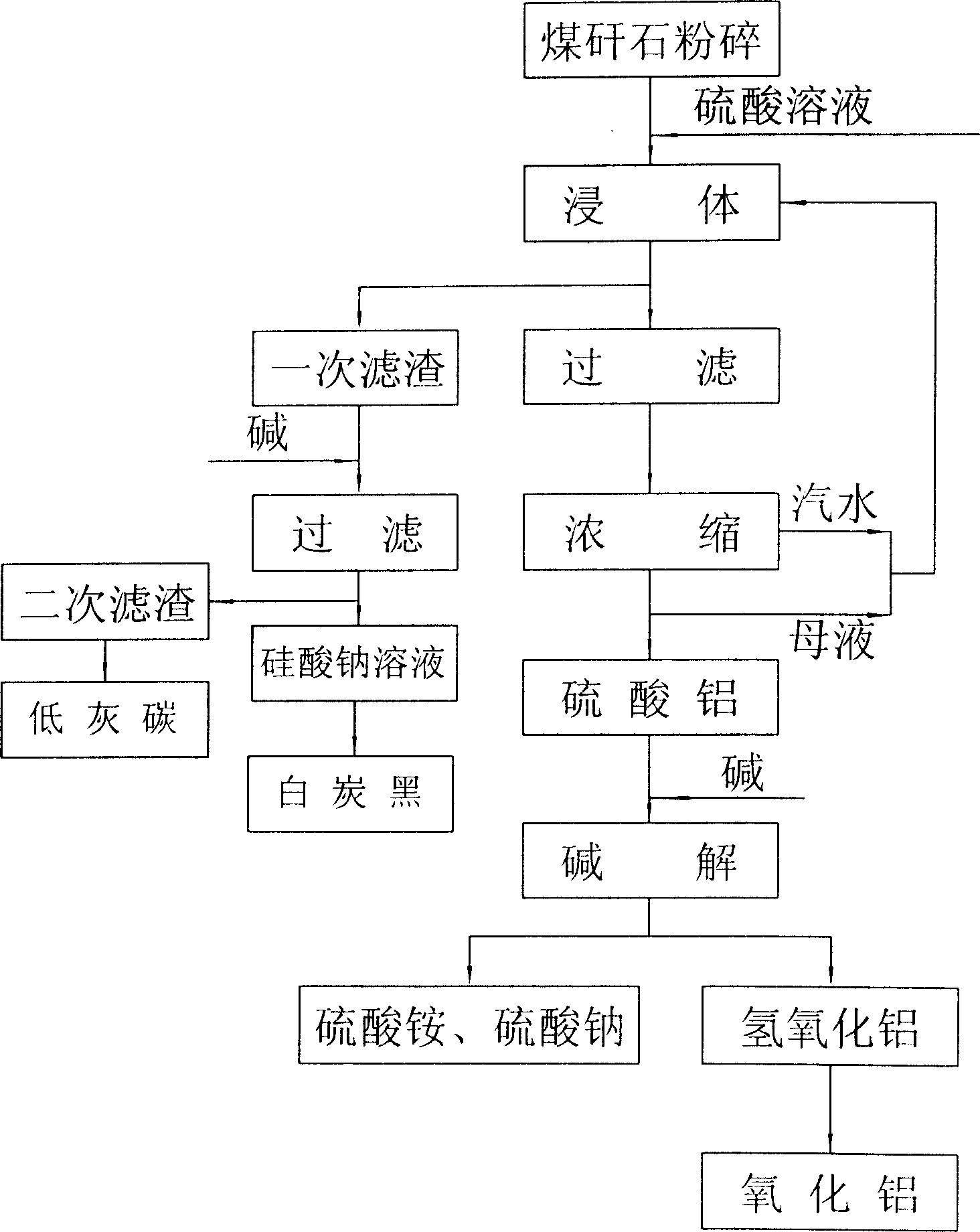

Method of coproducing aluminium oxide, white carbon black and low ash carbon by coal gangue ecological utilization

A technology of coal gangue and alumina, applied in chemical instruments and methods, silicon oxide, inorganic chemistry, etc., can solve the problems of acid recycling, environmental pollution, and low alumina recovery rate, and can solve environmental pollution and The effect of occupying land, simple technology and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take by weighing 25 grams of 180 purpose coal gangue fine powder, this gangue aluminum oxide content is 27.58%, silicon dioxide is 34.96%, fixed carbon 34%, surplus is other impurity, adding 100ML concentration is the sulfuric acid solution of 12 mol / liter, Add 2.5 grams of fluorite, heat to a slight boil, and keep for 2 hours. Then add 100 ml of hot water at 80° C., stir for 10 minutes, and filter while hot to obtain a filtrate containing aluminum ions and a primary residue. Wash the residue with 40 ml of hot water for 2-3 times, combine the filtrate, add 9 grams of ammonium sulfate under strong stirring, stir to completely dissolve the ammonium sulfate, then heat and concentrate to a liquid volume of about 150 ml, cool to room temperature, and crystallize And isolate 42 grams of ammonium alum, and the mother liquor is left as a circulating acid solution to enter the next extraction and use. Add 50ML of 25% caustic soda solution to the residue once, heat to boil and k...

Embodiment 2

[0026] Replace the above-mentioned coal gangue with 25 grams of coal series kaolinite with a carbon content of less than 5%. The gangue has an alumina content of 35.6%, a silicon dioxide content of 41.6%, fixed carbon content of 3.5%, and the balance being other impurities. Add fluorine Ammonium chloride is 2 grams, and other process parameters are basically unchanged, but the concentration of acid-extracted alumina is adjusted to 9 mol / liter; the amount of caustic soda solution added when extracting silicon oxide from the residue is increased to 60ML. The results show that the extraction rate of alumina is 88%, the extraction rate of aluminum by silicon oxide is 98%, and the coal with ash content less than 15% can be recovered.

Embodiment 3

[0028] In embodiment 1, the ammonium sulfate added is changed into potassium sulfate, and other processes are unchanged. The analysis shows that the extraction rate of alumina is 81%, the average extraction rate of silicon oxide is 94%, and the coal with ash content less than 30% can be recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com