Environment-friendly pulping agent and process

A kind of pulping and environmental protection technology, which is applied in the direction of pulping of cellulose raw materials, non-fiber pulp addition, inorganic compound addition, etc., can solve the problems of economic loss, wheat straw pulping pollution, wheat straw waste, etc., achieve short soaking time and benefit The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

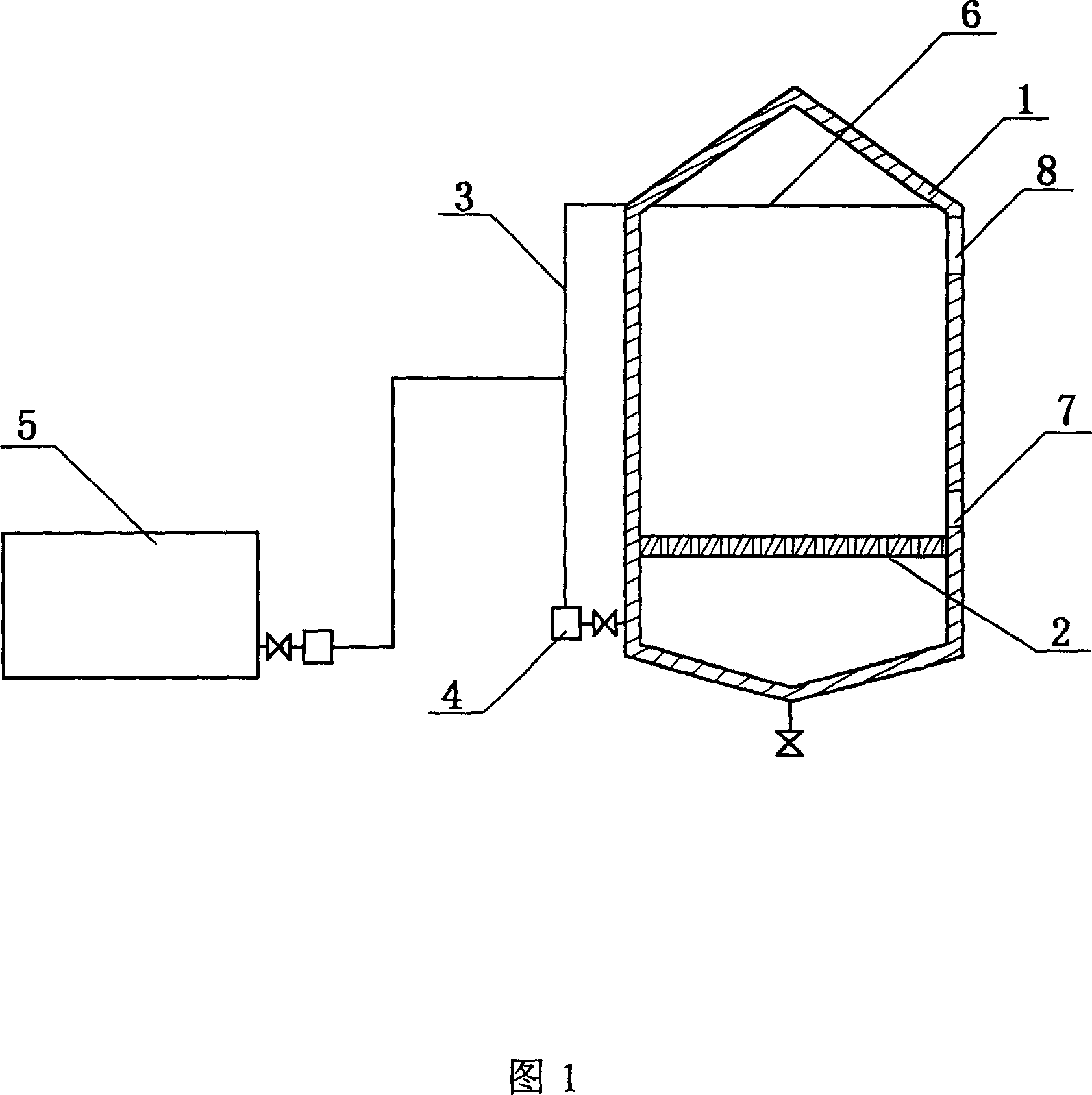

Image

Examples

Embodiment 1

[0028] Raw materials are prepared according to the following weight: 10 kilograms of animal oil, 30 kilograms of sodium dodecylbenzenesulfonate, 40 kilograms of alkaline hydrogen peroxide, 15 kilograms of sodium sulfite, and 5 kilograms of potassium ferricyanide, wherein, in alkaline hydrogen peroxide , 33 kg of sodium hydroxide and 7 kg of hydrogen peroxide.

[0029] Put 10 kg of animal oil into the mixer after dissolving it, add 33 kg of sodium hydroxide and 7 kg of hydrogen peroxide, start the mixer, saponify for 50 minutes, and then add 30 kg of sodium dodecylbenzenesulfonate. After mixing for 10 minutes, add 15 kg of sodium sulfite and 5 kg of potassium ferricyanide respectively. The whole raw material can be discharged after mixing for 30 minutes, and it can be made into a pulping agent after solidification and drying.

[0030] 12 kilograms of pulping agent made above and 0.8 kilograms of magnesium oxide are put into 400 kilograms of water and mix to make the mixed aque...

Embodiment 2

[0039] Except that the raw material consumption of environment-friendly pulping agent is different from embodiment 1, all the other are all the same as embodiment 1.

[0040] The raw material consumption of this embodiment is: 12 kilograms of animal oils, 28 kilograms of sodium dodecylbenzenesulfonate, 42 kilograms of alkaline hydrogen peroxide, 15 kilograms of sodium sulfite, 3 kilograms of potassium ferricyanide, wherein, in alkaline hydrogen peroxide Among them, sodium hydroxide is 36 kilograms, and hydrogen peroxide is 6 kilograms.

Embodiment 3

[0042] Except that the raw material consumption of environment-friendly pulping agent is different from embodiment 1, all the other are all the same as embodiment 1.

[0043] The raw material consumption of this embodiment is: 8 kilograms of animal oil, 32 kilograms of sodium dodecylbenzene sulfonate, 38 kilograms of alkaline hydrogen peroxide, 14 kilograms of sodium sulfite, 8 kilograms of potassium ferricyanide, wherein, in alkaline hydrogen peroxide Among them, sodium hydroxide is 30 kilograms, and hydrogen peroxide is 8 kilograms.

[0044] The product obtained in this example is analyzed for cellulose, and the result is that the coarse pulp is whitish, easy to bleach, soft fiber, not delicate pulp, good water drainage performance, good brightness and high strength. The yield of white pulp is 65%, and the whiteness is 80-85%.

[0045] In the process of the present invention, the recovery and utilization of the medicinal liquid extruded from the pulping machine is an import...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com