Method of thermo press preparing high purity aluminium titanium carbide block material

A block material, aluminum-titanium carbide technology, applied in the field of ceramic block preparation, can solve the problems of furnace body and heating element corrosion and environmental pollution, etc., achieve easy and stable sintering process parameters, simple process flow, and avoid thermal explosion reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

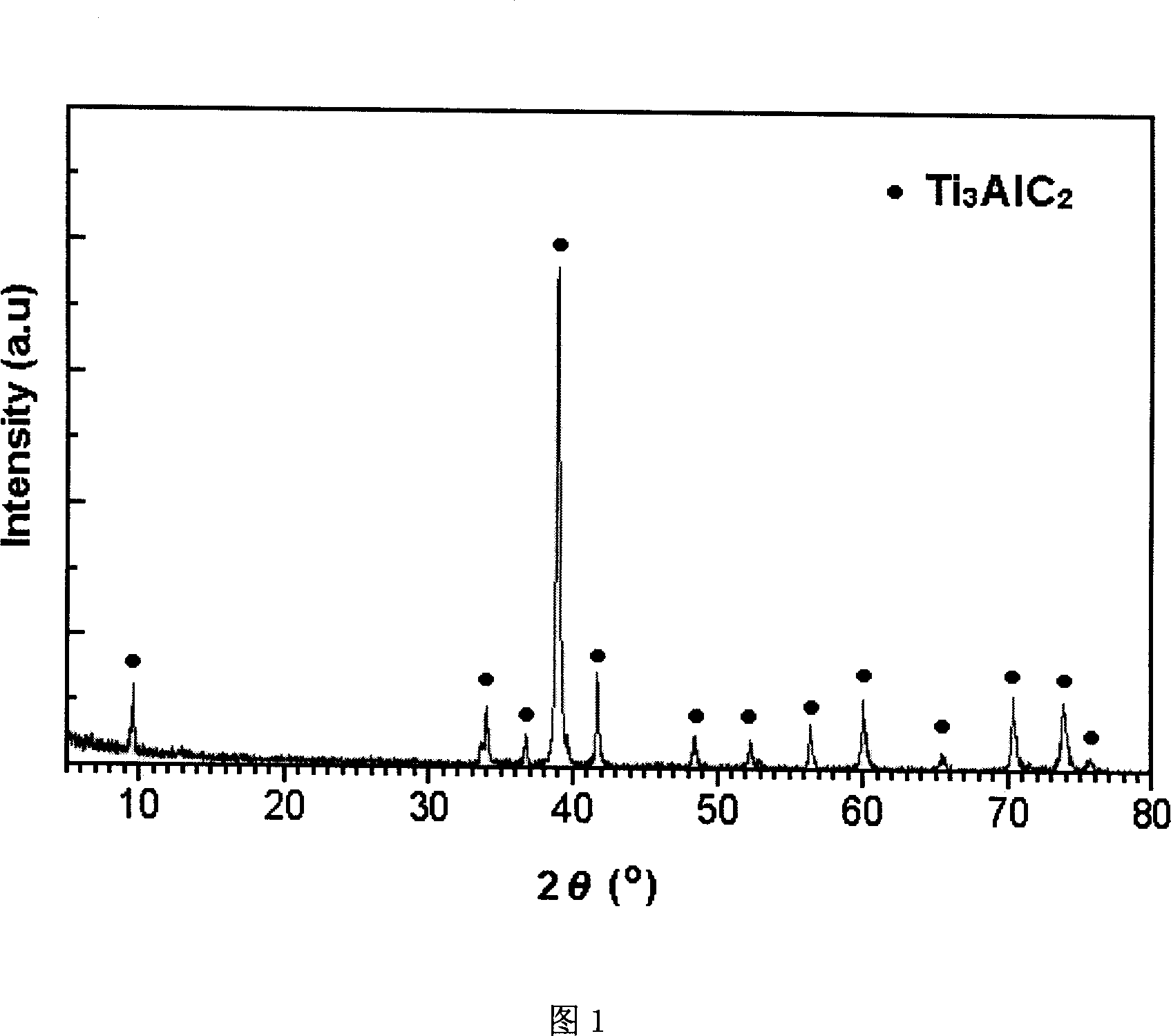

[0020] 1) According to the molar ratio of Ti:Al:TiC:Sn=1:1:1:0.1, weigh 14.68 grams of Ti powder, 8.29 grams of Al powder, 18.38 grams of TiC powder, and 3.64 grams of Sn powder. 2) Put the above-mentioned ingredients and agate balls into a ball mill jar according to the ball-to-material ratio of 2:1, and mix for 5 hours. 3) Put the uniformly mixed ingredients into the graphite mold, place the graphite mold in a hot-press furnace, and raise the temperature of the furnace to 1350°C at a heating rate of 30°C / min under an argon protective atmosphere. A pressure of 20 MPa is applied to the powder, and the holding time is 40 minutes to obtain high-purity Ti 3 AlC 2 Dense bulk material. The x-ray diffraction (XRD) pattern of this material is shown in accompanying drawing 1. It can be seen from the figure that the product has high purity, and there is no impurity phase such as TiC in the XRD pattern.

Embodiment approach 2

[0022] 1) According to the molar ratio of Ti:Al:TiC:Sn=1:1:1:0.15, weigh 14.12 grams of Ti powder, 7.97 grams of Al powder, 17.66 grams of TiC powder, and 5.25 grams of Sn powder. 2) Put the above-mentioned ingredients and agate balls into a ball mill jar according to the ball-to-material ratio of 2:1, and mix for 5 hours. 3) Put the uniformly mixed ingredients into the graphite mold, place the graphite mold in a hot-press furnace, and raise the temperature of the furnace to 1400°C at a rate of 40°C / min under an argon protective atmosphere, and at the same time heat the powder in the mold A pressure of 20MPa was applied to the material, and the holding time was 30 minutes to obtain high-purity Ti 3 AlC 2 Dense bulk material. Its XRD result is the same as Embodiment 1.

Embodiment approach 3

[0024] 1) According to the molar ratio of Ti:Al:TiC=1:0.9:1, weigh 16.29 grams of Ti powder, 8.26 grams of Al powder and 20.37 grams of TiC powder. 2) Put the above-mentioned ingredients and agate balls into a ball mill jar according to the ball-to-material ratio of 2:1, and mix for 8 hours. 3) Put the uniformly mixed ingredients into a graphite mold, place the graphite mold in a hot-press furnace, and raise the temperature of the furnace to 1500°C at a rate of 40°C / min under an argon protective atmosphere, while the powder in the mold is A pressure of 30MPa was applied to the material, and the holding time was 60 minutes to obtain high-purity Ti 3 AlC2 Dense bulk material. Its XRD result is the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com