A method for quantitative determination of content of triglyceride in pulp resin

A technology for quantitative determination of triglycerides, which is applied in the preparation of test samples, material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions. It can solve the problems that are difficult to achieve quantitative analysis, Control process conditions can not be optimal screening and other issues, to achieve rapid measurement results, satisfactory precision, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

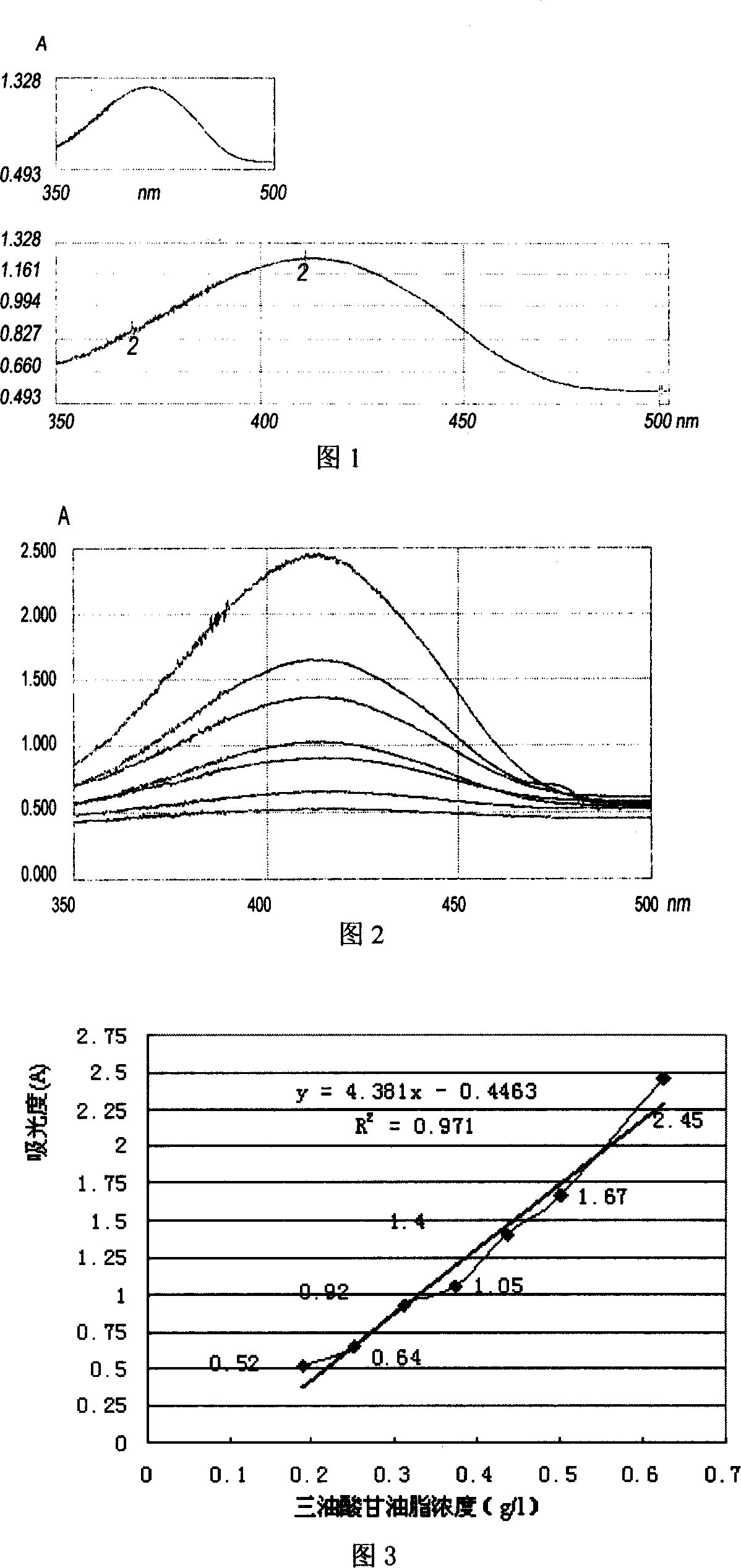

Method used

Image

Examples

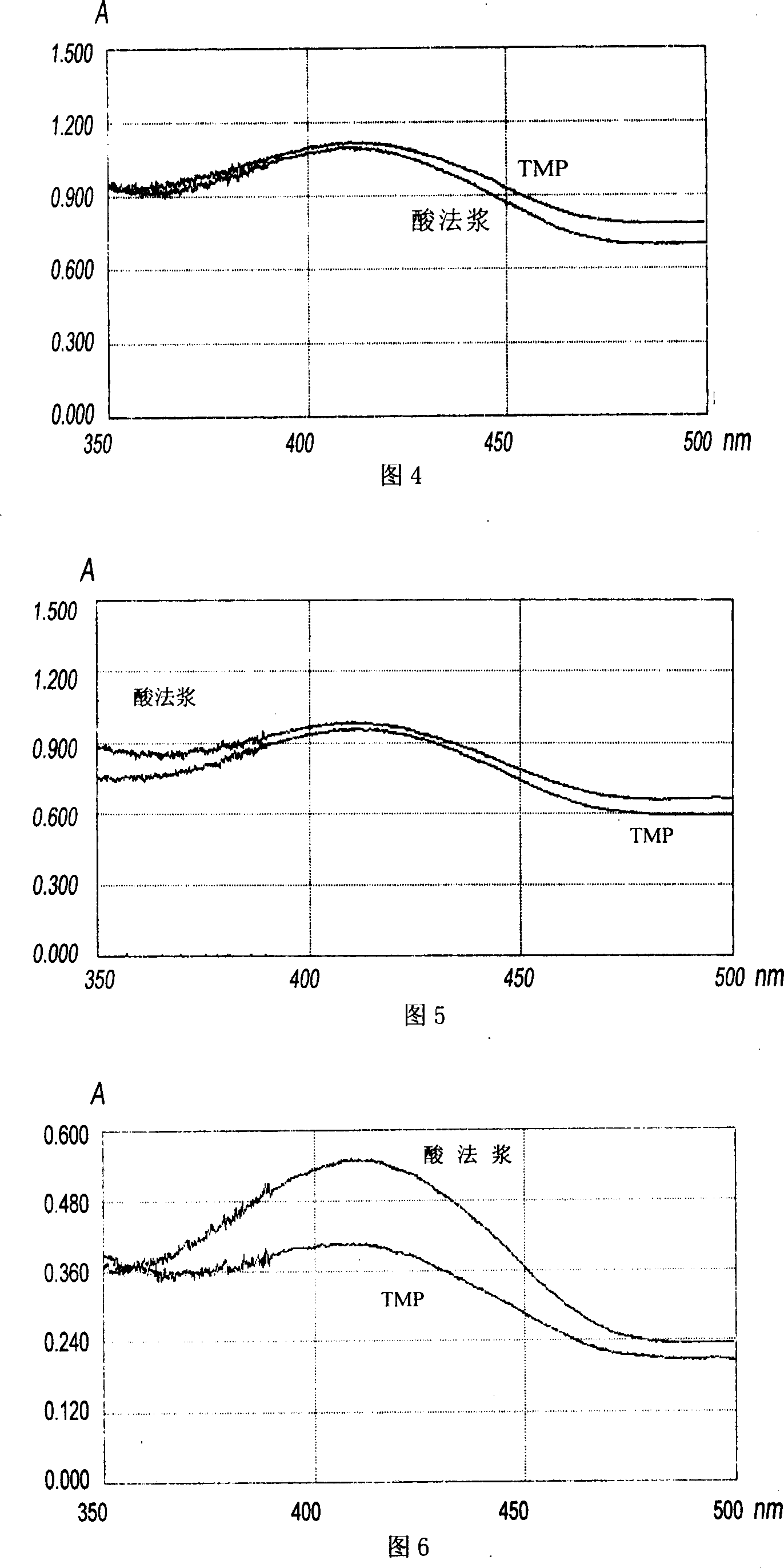

Embodiment 1

[0040] Weigh 8g of absolute-dried masson pine TMP, extract with n-hexane at 90°C for 3 hours, and reflux 8 times per hour. After the extraction, recover n-hexane, use distilled water to clean the bottom bottle, dry and weigh at 80°C, Dissolve the extract in 25ml isopropanol to be tested;

[0041] Weigh 8g of absolute dry acidic sulfite slurry, extract with n-hexane at 90°C for 3 hours, reflux 8 times per hour, recover n-hexane after extraction, wash the bottom bottle with distilled water, dry and weigh at 80°C Heavy, the extract is dissolved in 25ml of isopropanol to be tested;

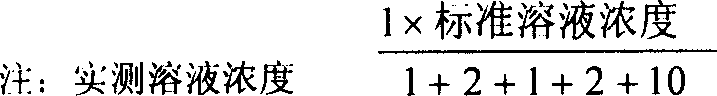

[0042]Pipette 2ml of the sample into a 30ml brown reaction bottle, add 2ml of KOH solution with a mass percent concentration of 5%, react at 50°C for 15min, cool to 25°C, then add 1ml of 0.1mol / l KCl solution, 2ml of acetic acid and high The mixed solution of sodium iodate (the mixed solution of acetic acid and sodium periodate is formed by mixing equal volumes of 2mol / l acetic acid solution and 0.05...

Embodiment 2

[0053] Weigh 8g of absolute dry masson pine TMP, dissolve it in 265ml of water to make the pulp concentration 3%, place it in a 500ml Erlenmeyer flask at pH 7.5 and temperature 40°C, wash it in a constant temperature shaker for 2h, and then Vacuum filter the pulp, dry naturally for n-hexane extraction, extract for 3 hours, reflux 10 times per hour, recover n-hexane after extraction, wash the bottom bottle with distilled water, dry and weigh at 80°C, and extract The substance is dissolved in 25ml isopropanol to be tested;

[0054] Weigh 8g of dry acidic sulfite pulp, dissolve it in 265ml of water to make the pulp concentration 3%, put it in a 500ml Erlenmeyer flask at pH 7.5 and temperature 40°C, and wash it in a constant temperature shaker for 2h , the pulp was vacuum filtered, dried naturally for n-hexane extraction, extracted for 3 hours, refluxed 10 times per hour, recovered n-hexane after extraction, cleaned the bottom bottle with distilled water, dried and weighed at 80°C...

Embodiment 3

[0066] Measure 265ml of an aqueous solution containing 4mg of lipase reagent, suspend 8g of absolute dry masson pine TMP in the solution at pH 7.5 and temperature 40°C, make the pulp concentration 3%, put the pulp enzyme mixture in a 500ml Erlenmeyer flask React in a constant temperature shaking table for 2 hours, then vacuum filter the pulp, dry it naturally for n-hexane extraction, extract for 3 hours, reflux 9 times per hour, recover n-hexane after extraction, use distilled water to clean the bottom bottle, and Dry and weigh at 80°C, then dissolve the extract in 25ml of isopropanol for testing;

[0067] Measure 265ml of an aqueous solution containing 4mg of lipase reagent, suspend 8g of dry acidic sulfite pulp in the solution at pH 7.5 and temperature 40°C to make the pulp concentration 3%, put the pulp enzyme mixture in a 500ml cone React in a constant temperature shaker in a shaped bottle for 2 hours, then vacuum filter the pulp, dry it naturally for n-hexane extraction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com