Oil displacement method by injecting indigenous microorganism into sewage

A technology of original microorganisms and oil displacement method, which is applied in the field of oil displacement where sewage is injected into original microorganisms, can solve the problems of not maximizing the function of original microorganisms, few types of development, and decline in effect, so as to avoid strain variation and degradation, The effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

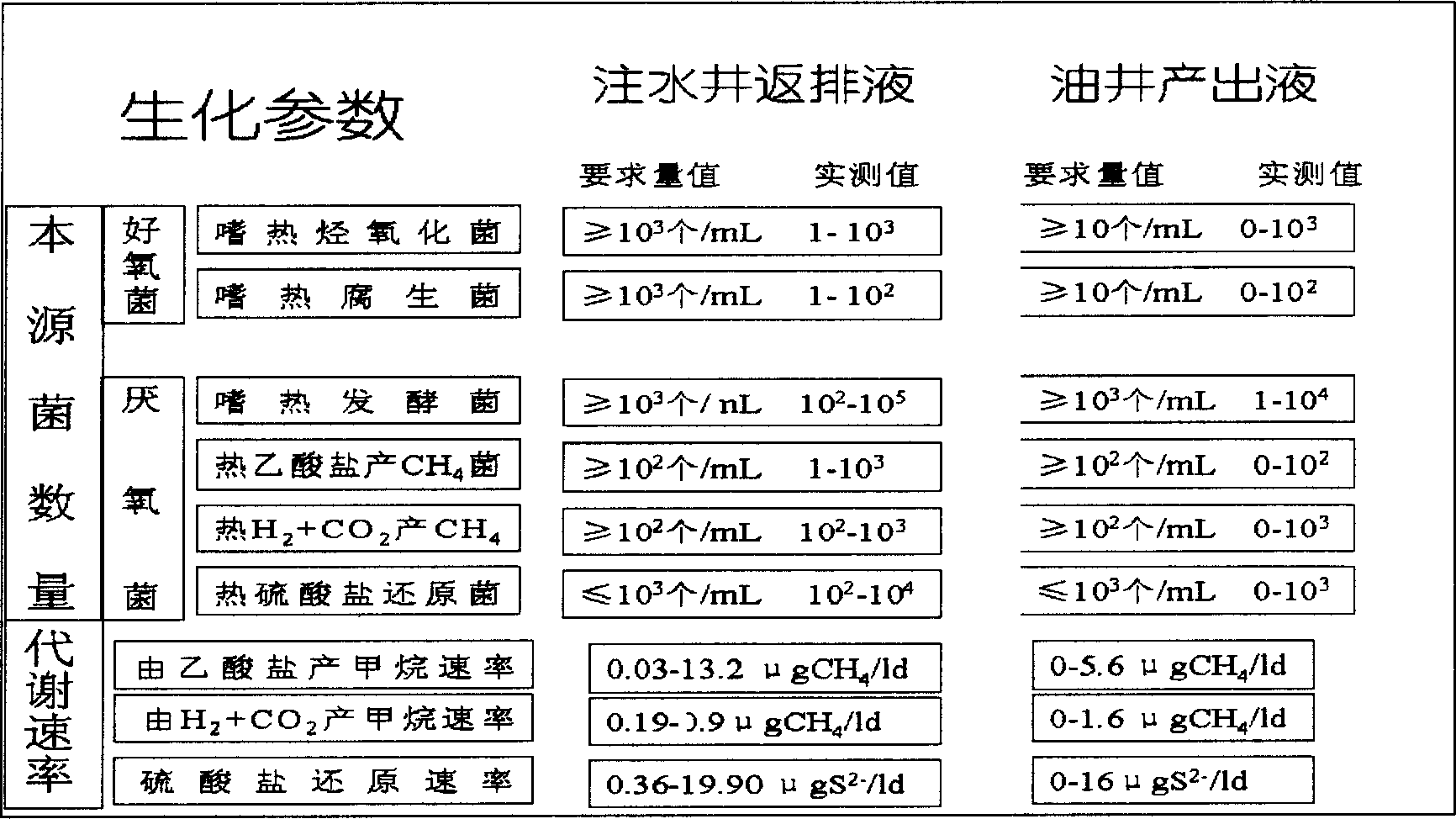

[0015] Firstly, investigate the microbes in the reservoir, and the quantity and metabolic performance of the microbes used in the survey should meet the requirements described in Table 1; secondly, within the range of geological parameters, the reservoir temperature should be less than 75°C, The optimal temperature range is 30-55°C; the salinity of the reservoir water is less than 50,000mg / L, and the hydrogen sulfide content in the reservoir water is less than 50mg / L; thirdly, according to the biochemical parameters of the microorganisms in the reservoir, determine the nutrients according to the amount of injected sewage The ratio is 0.45-1.40% for nitrogen source and phosphorus source, 0.1% for acetate and 0.01% for organic auxin yeast powder.

[0016] Air consumption is 10m per meter of oil layer 3 Air volume under standard conditions; Fourth, the replenishment of carbon sources depends on the remaining oil saturation of 1.5m near the reservoir water injection well being con...

Embodiment 2

[0021] The number of beneficial microorganisms in the sewage is lower than 10-10 3 pcs / mL, 8m flow back from the water injection well 3 liquid, and then take back effluent 5m 3 Fermented as a seed liquid at the temperature of the surface oil reservoir, the total amount of fermentation liquid is 6m 3 , ie 5m 3 seed liquid and 1m 3 Fermentation medium; fermentation medium by volume percentage 1m 3 Inorganic salt containing nitrogen and phosphorus is 0.2%, acetate is 0.3%, liquid paraffin is 1% and the rest is water; first, 1m 3 The prepared culture medium and fermenter were sterilized at 121°C for 30 minutes at 0.1MPa. When the temperature dropped to the oil reservoir temperature, the seed solution was added and fermented at the oil reservoir temperature. At the same time, the mixed solution was ventilated at 0.5m3 per minute. Ventilation, monitor the number of bacteria every 12 hours, until the number of bacteria reaches 3×10 8 per mL, the fermentation is over.

[0022] ...

Embodiment 3

[0024] Dagang Kongdian Oilfield was put into water injection development in February 1979. The reservoir of Guantao Formation is fluvial facies deposit with good reservoir physical properties (porosity 33%, permeability 1.878μm 2 ). The edge and bottom water in the oil field is developed, and about 40% of the wells have bottom water reservoirs. The underlying crude oil has a viscosity of 73mPa.s, a density of 0.9535, and an average water content of 94.4%. There is no replacement capacity. On the basis of analyzing reservoir conditions and biochemical parameters (Table 2), a scheme for periodically injecting aerated nutrient solution was formulated. The formula ratio of the nutrient solution was the same as in Example 1, and the carbon source was added. The method was the same as in Example 1, and the fermentation Original bacterium liquid, culture method is with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com