Aromatic substituted nonionic surfactants in soil prevention, reduction or removal in treatment zones

a non-ionic surfactant and aromatic technology, applied in the direction of detergent compounding agents, sulfur compounds, separation processes, etc., can solve the problems of reducing the overall treatment undesirable soil formation or accumulation on hard surfaces or in treatment zones, and reducing the efficiency of chemical treatment, so as to achieve enhanced malodor removal and effective scrubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

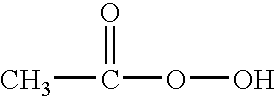

Method used

Image

Examples

working example 1

Scale Control on Plastic Parts

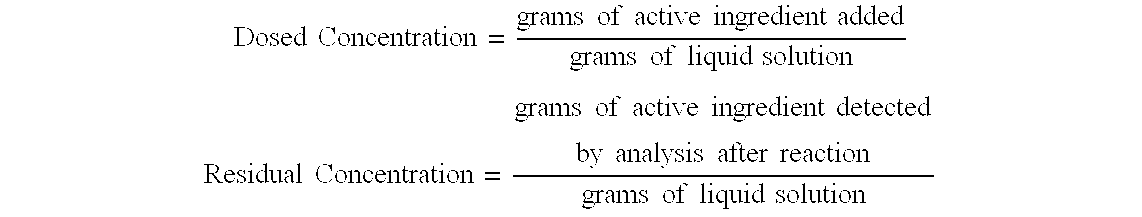

[0071] The objective of this example was to evaluate a variety of nonionic structural features for effecting inorganic scale removal from plastic parts. It was desired to establish a correlation between scale control, scale removal, HLB, and foaminess.

[0072] The unexpected results are shown in Table 1. First, the best (<90%) inorganic-sulfur scale removal was found for benzylated noninoics (experiments 1-3). However, benzylation is not an exclusive feature for performance since the alkylated benzyl-ethoxylate of experiment 9 proved to be ineffective for scale removal. This is evidenced by comparing the benzylated experiments vs. their uncapped homologues; cf., experiments 1 vs. [10 or 7 or 13], 2 vs. 11 and 3 vs. 5. Note that the benzylated nonionic of experiment 9 performed much worse than the non-benzylated homologue of experiment 6.

[0073] Also, the presence of propoxylation--in combination with aromatic moieties in the molecule (alkyl-aryl, benzylati...

working example 2

Scale Control in Air Scrubbing Equipment

[0075] The objective of this example was to compare the industrial plant air scrubbing process which uses no surfactants--for scale control--to one which uses an aromatic capped nonionic surfactant. The evaluation was done in an industrial feather hydrolyzer air scrubber which operates with a continuously increasing scale loading, in the piping and packing materials, that must be cleaned on a monthly basis. When the test began the piping was about 50% plugged and the packing material about 20% with a scale that was, analyzed and, found to be >96% elemental sulfur with some inorganic carbonates. The differential pressure of the malodorous air stream was 4.6 psi.

[0076] For the control study, a standard air scrubbing program using chlorine gas and sodium hydroxide was run; maintaining a pH>11.0 and a titratable chlorine level of >500 ppm. The system was pre-inspected in the scrubber piping and packing material. The system was run for time periods...

working example 3

Carbonate and Silicate Control in Air Scrubbing Equipment

[0077] The objective of this example was to test additional inorganic soils deposited on air scrubbing equipment. The evaluation was done in an industrial room air scrubber which continuously removes malodorous gases and particles from carcass cooking and blood drying operations. When the test began the scrubber surface and packing material were completely covered with a whitish scale to a depth of about 0.9 cm. This scale had been analyzed by IR and EDS and was found to be about 30% calcium cabonate and about 70% inorganic metal silicates. The system was pre-inspected in the scrubber piping and packing material. The nonionic, 500 ppm of a di-benzylated modified ethylene oxide / propylene oxide, surfactant was supplied without other adjuvants into the aqueous scrubber and the system was run for about 9 hours with intermittent inspections. The results are shown in Table 3, and indicate essentially complete removal of the inorgani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com