Method and apparatus for growing silicon carbide crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] As will be readily apparent to those skilled in the art, the following disclosure may be easily adapted and incorporated into virtually all known methods for producing SiC crystals. Accordingly, the following detailed description will begin with a general discussion of the invention. Additional embodiments demonstrating the versatility of the invention will follow.

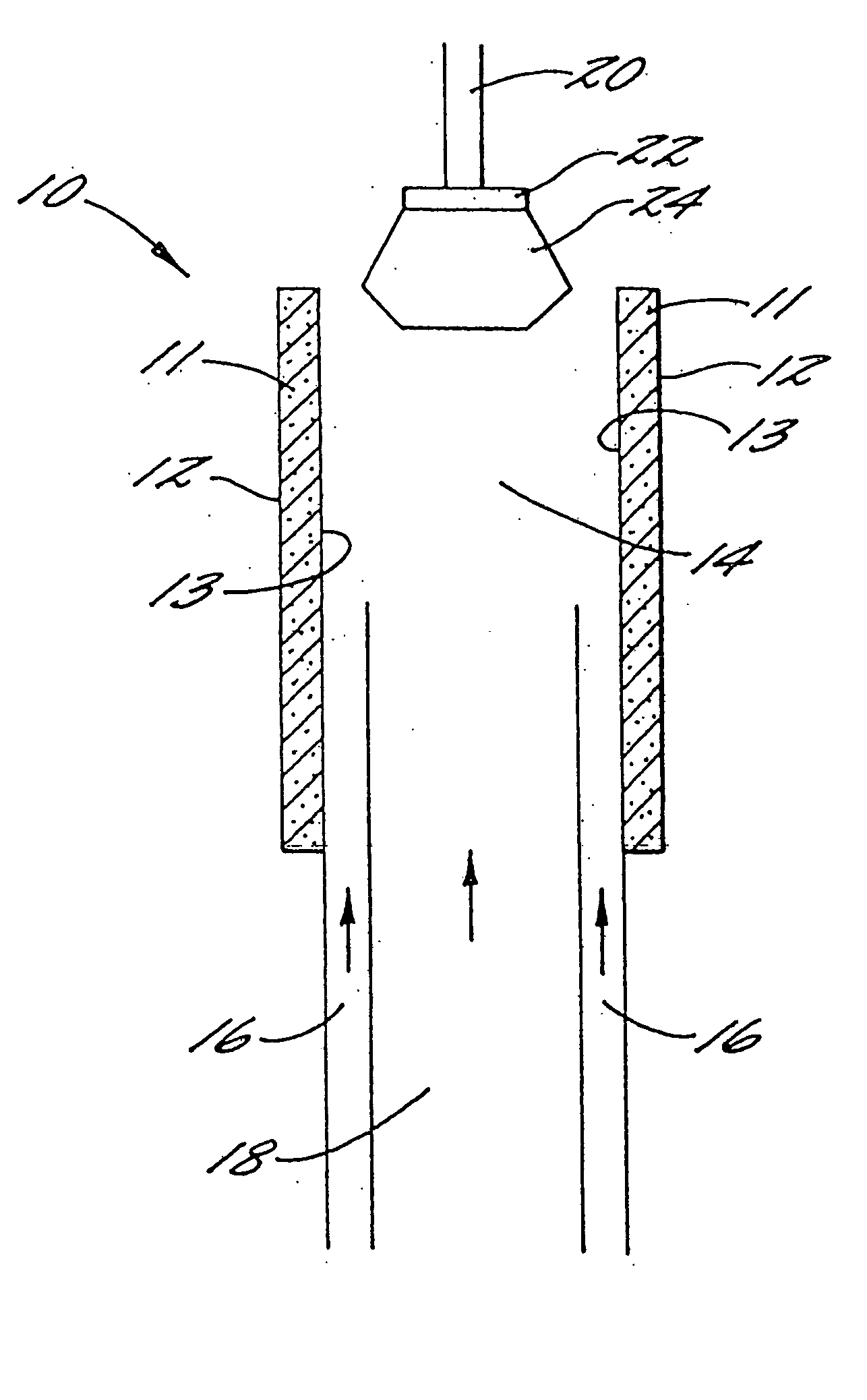

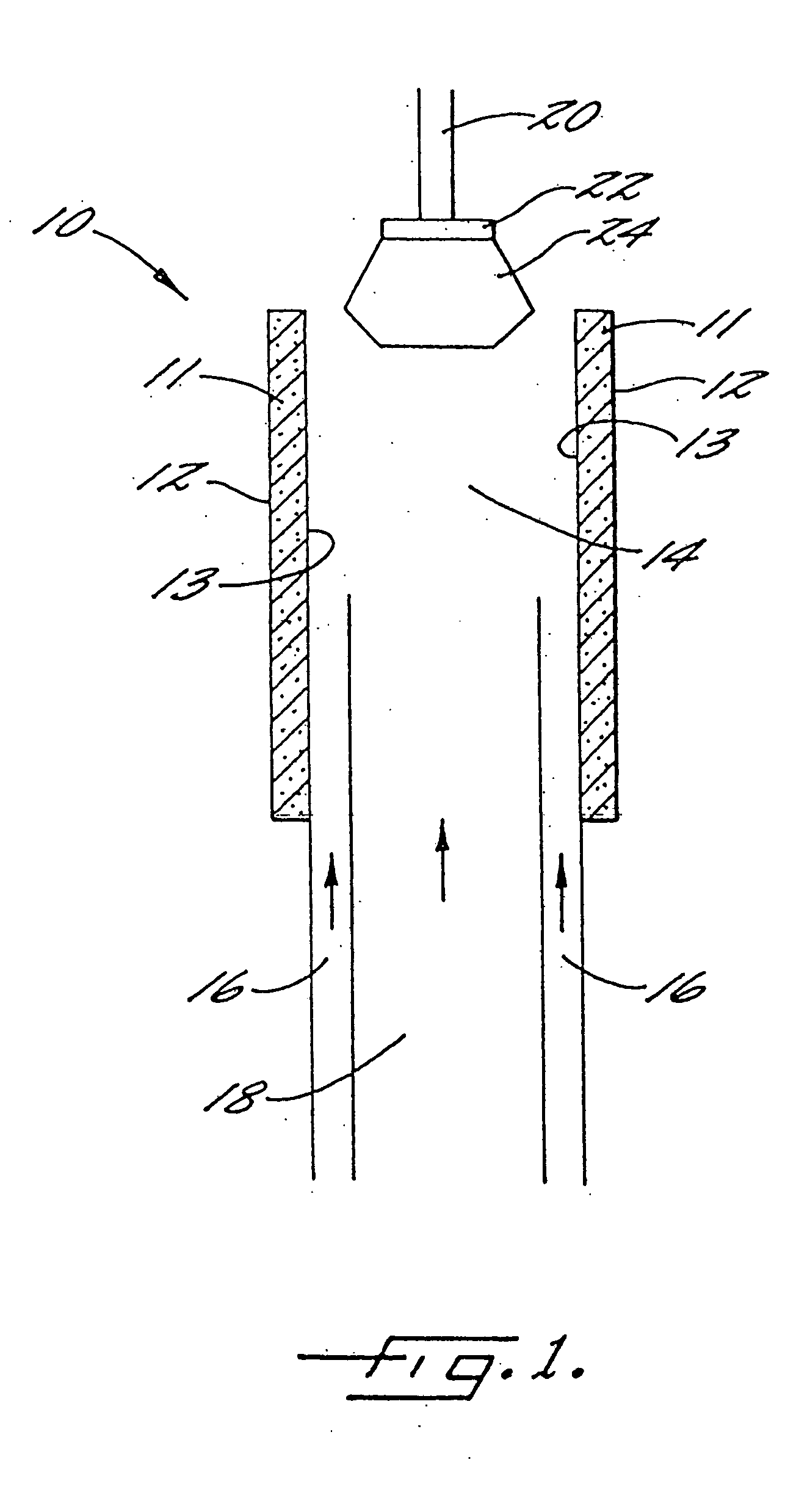

[0041] A preferred embodiment of the invention is a gas fed sublimation (GFS) system in which the source of silicon and the source of carbon are gaseous. The gaseous silicon and carbon sources are fed to a reaction chamber where they react at high temperatures, typically above 2000° C., to form vaporized species containing silicon and carbon. In addition to carbon (C) and silicon (Si), such species typically include SiC, Si2C, and SiC2 The vaporized species are then deposited onto a monocrystalline seed crystal of a desired polytype. Such a system is schematically disclosed in FIG. 1.

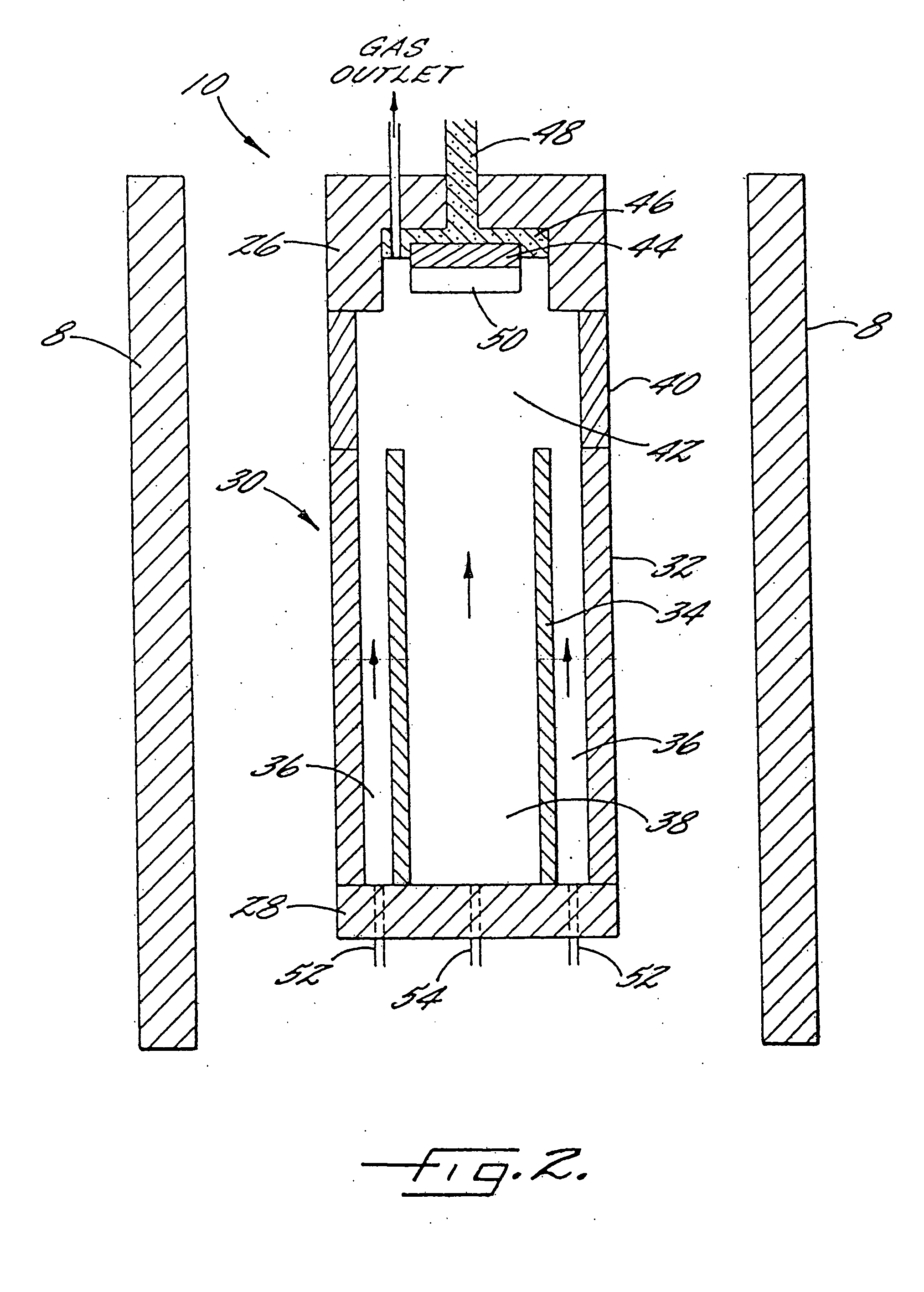

[0042] The GFS system of FIG. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap