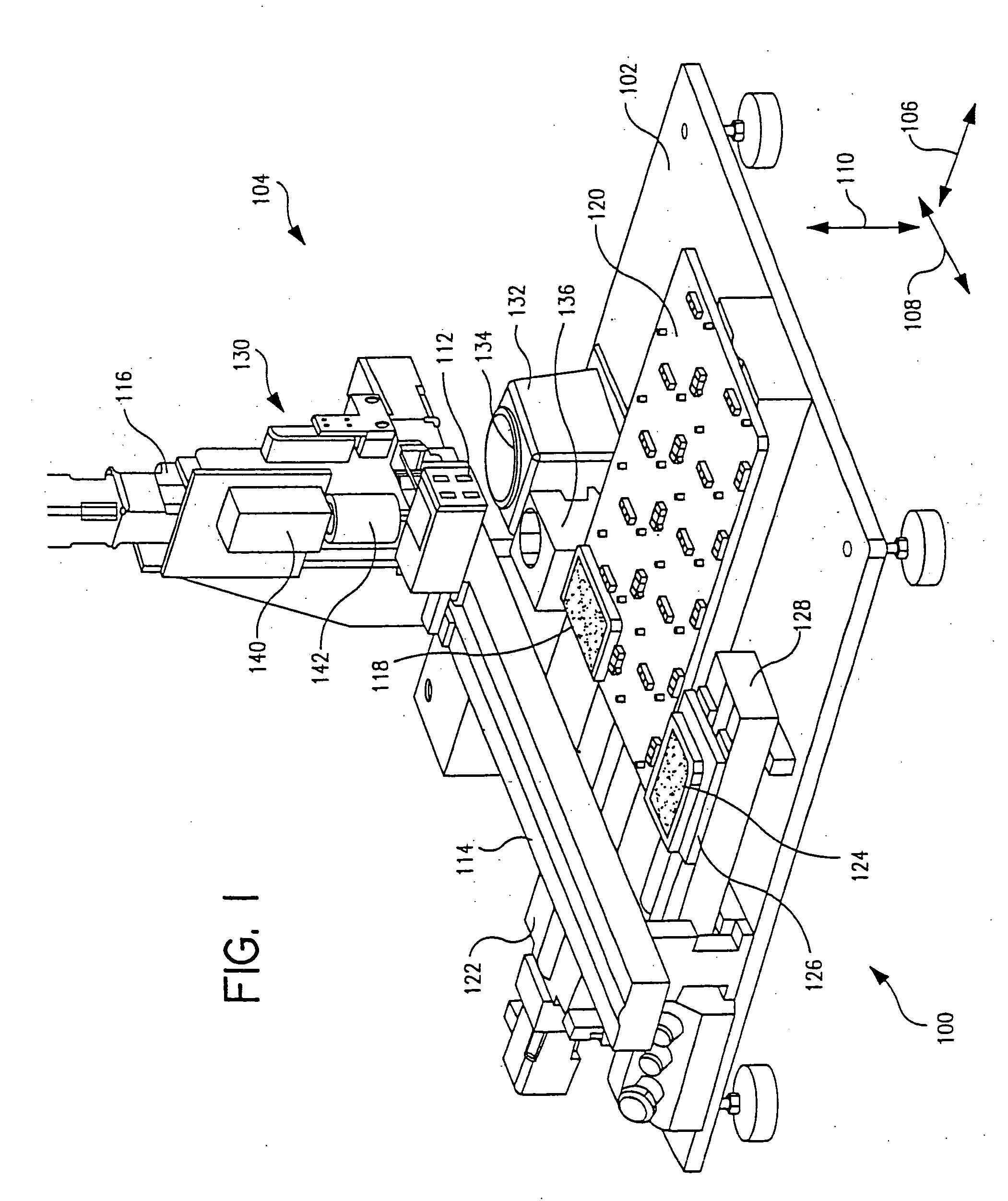

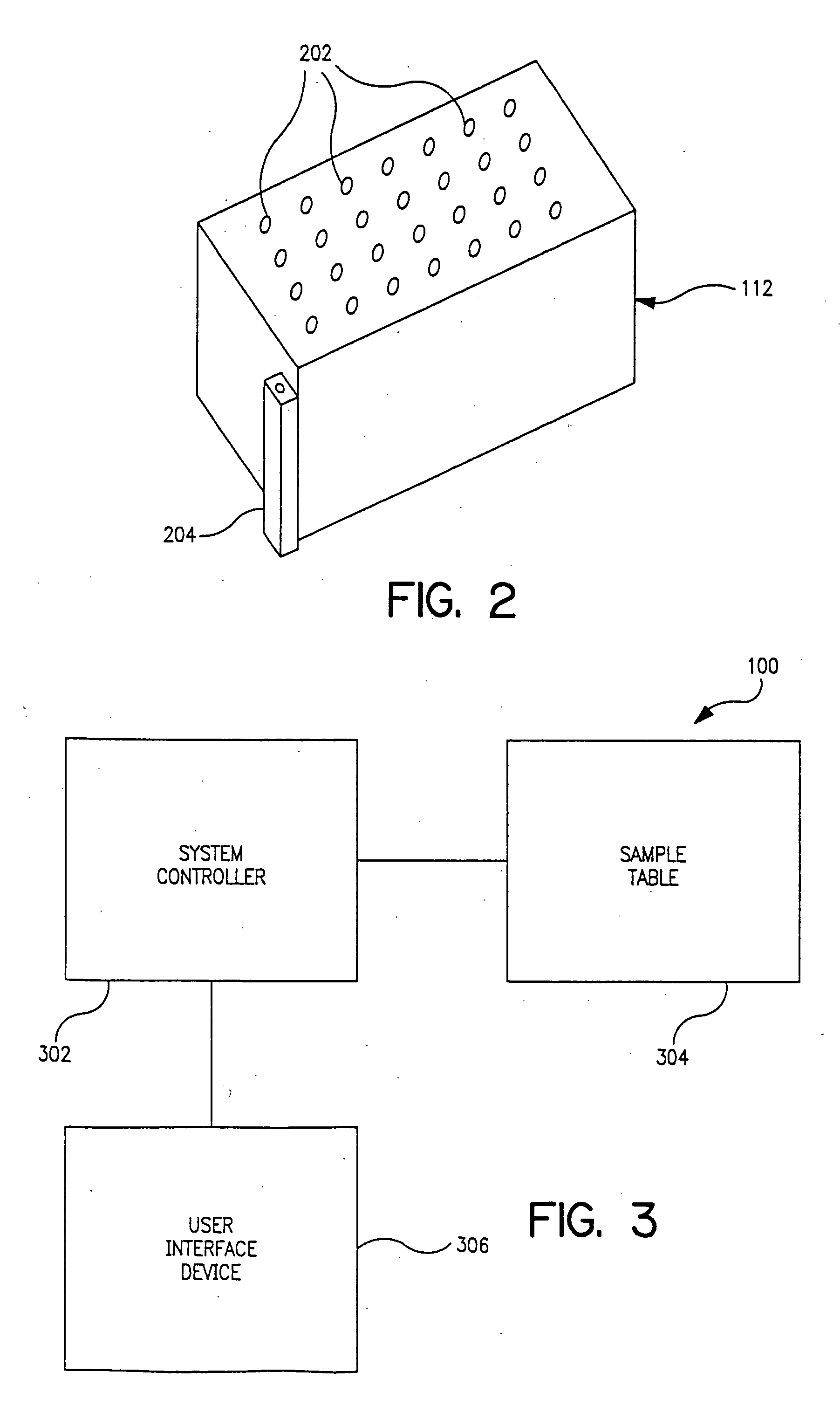

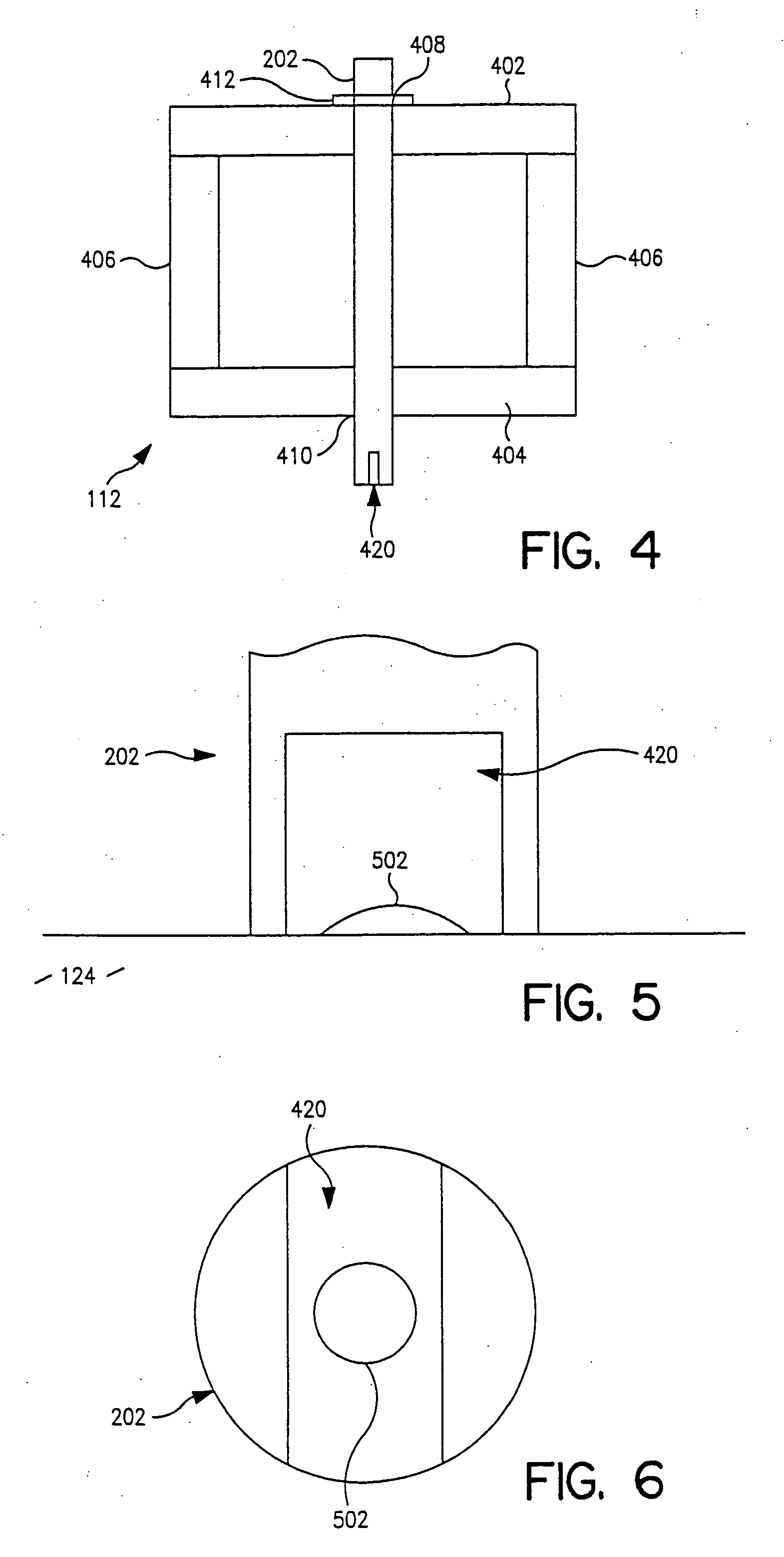

Method and apparatus for delivery of submicroliter volumes onto a substrate

a technology of submicroliter volume and substrate, applied in the field of sample dispensing systems, can solve the problems of pin tools being difficult to use pin tools can be problematic for high throughput systems, and pin tools cannot be used in contact dispensing situations,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0123] A flat substrate containing an array of less hydrophobic elements surrounded by more hydrophobic elements, was prepared with an array of photoresist elements. To prepare the array, silicon dioxide (SiO2) was grown on silicon wafers to a height of 3025 angstroms, ±5%. Alternatively, the SiO2 can be grown to a height of about 1050 angstroms. This process is performed by a “wet oxidation” method in which H2 and O2 gases are used in converting the Si to SiO2.

[0124] A photoresist material (such as “AZ 111 XFS” photoresist from Clariant Corporation of Charlotte, N.C., USA) was spun onto the SiO2 to a thickness of 0.2 μm to 1.22 μm, with a height of about 1.0 μm. The photoresist was solidified by baking at 65 degrees Celsius for two to three minutes. The surface was then exposed to light of 365 nm wavelength through a mask that blocked light at the target locations. The photoresist that was exposed to light in the unmasked portions of the substrate was then washed off with a phosph...

example 2

[0126] In another process provided herein, a microarray was produced with a flat starting substrate having an array of SiO2 elements surrounded by a silane surface, thereby creating an array of elements less hydrophobic than the surrounding area. The resulting substrate has target locations that are bare silicon dioxide, and the surrounding regions are silated with DMDCS.

[0127] Silicon dioxide was grown on silicon wafers to a height of 3025 Angstroms±5%. Alternatively, the SiO2 can be grown to a height of about 1050 angstroms. This process is performed by a “wet oxidation” method in which H2 and O2 gases are used in converting the Si to SiO2.

[0128] The resulting substrate was patterned with “MEGAPOSIT” SPR 900-0.8 photoresist from Shipley Company, L.L.C. of Marlborough, Mass., USA in the manner described above in Example 1. The wafer was then baked at 70° C. for 30 minutes to remove any remaining solvents. The patterned substrate was silated with 3.5% DMDCS for twenty minutes, as ...

example 3

[0129] In another process, a microarray was produced using a flat substrate having an array of SiO2 elements surrounded by a TEFLON® (polytetrafluoroethylene (PFTE)) surface, to create an array of target elements less hydrophobic than the surrounding area.

[0130] Silicon dioxide was grown on silicon wafers to a height of 3025 Angstroms±5%. Alternatively, the SiO2 can be grown to a height of about 1050 angstroms. This process is performed by a “wet oxidation” method in which H2 and O2 gases are used in converting the Si to SiO2.

[0131] The resulting substrate was patterned with “MEGAPOSIT” SPR 900-0.8 photoresist from Shipley Company, L.L.C. of Marlborough, Mass., USA as described above for Example 1. The resulting substrate was baked as in Example 2.

[0132] The patterned substrate was coated with a TEFLON® (polytetrafluoroethylene (PFTE)) coating, such as “PerFluoroCoat” from Cytonix Company of Beltsville, Md., USA, to a height of 148 to 1200 Angstroms. The photoresist pads were rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com