[0007] According to the present invention, techniques for fabricating

integrated circuit devices are provided. More particularly, the invention provides a method and structure for a non-

volatile memory device, commonly called a metal

oxide-

nitride-oxide on

silicon (“MONOS”) memory device. Merely by way of example, the present invention provides a method for

processing a

cell region of the MONOS memory separately while protecting peripheral regions of the device for efficiency and improvement in device characterization. The peripheral regions are then processed while protecting the

cell region in other embodiments. Certain steps are performed to process both the peripheral and

cell region for efficiency and improved

process integration purposes.

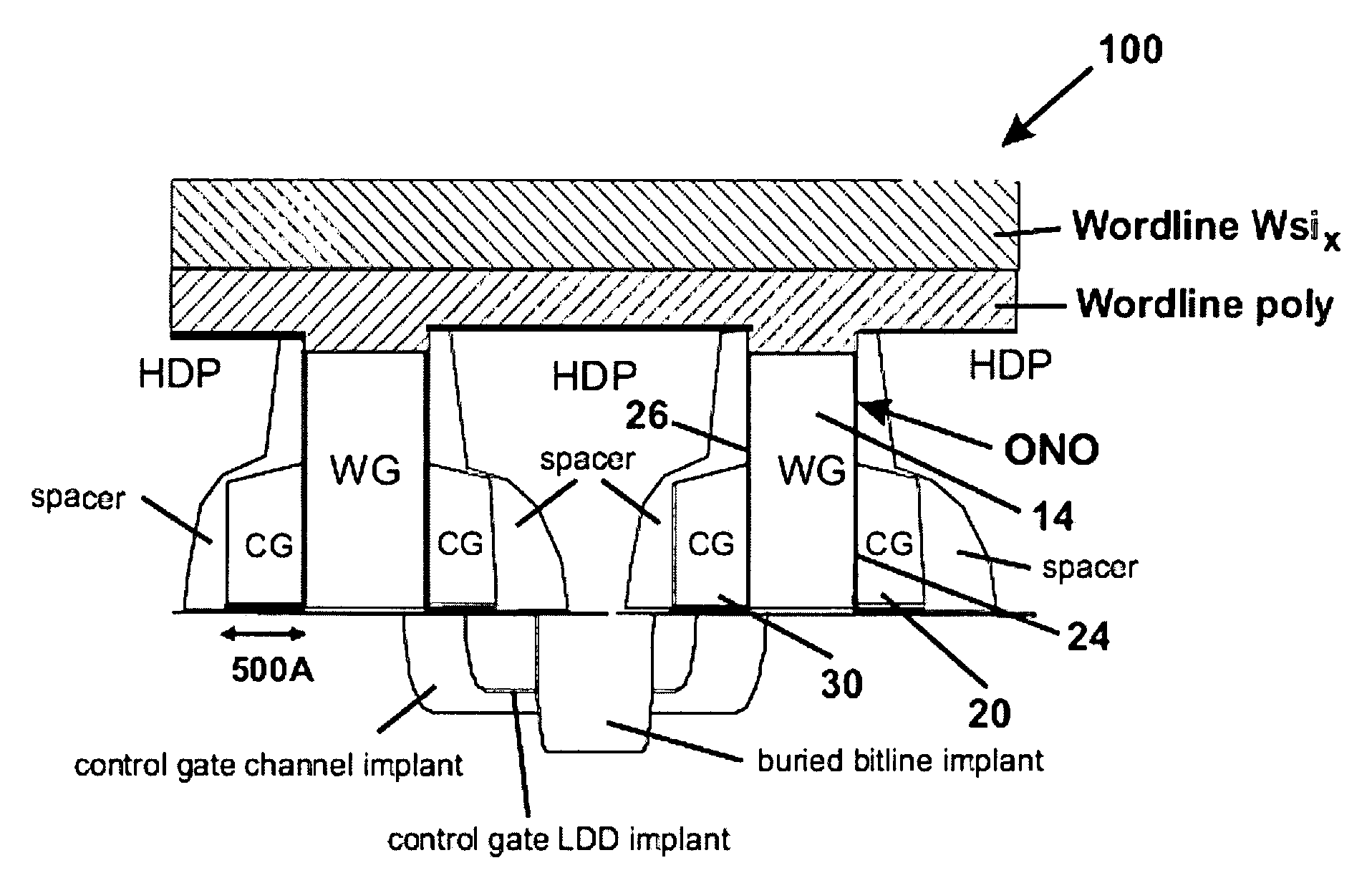

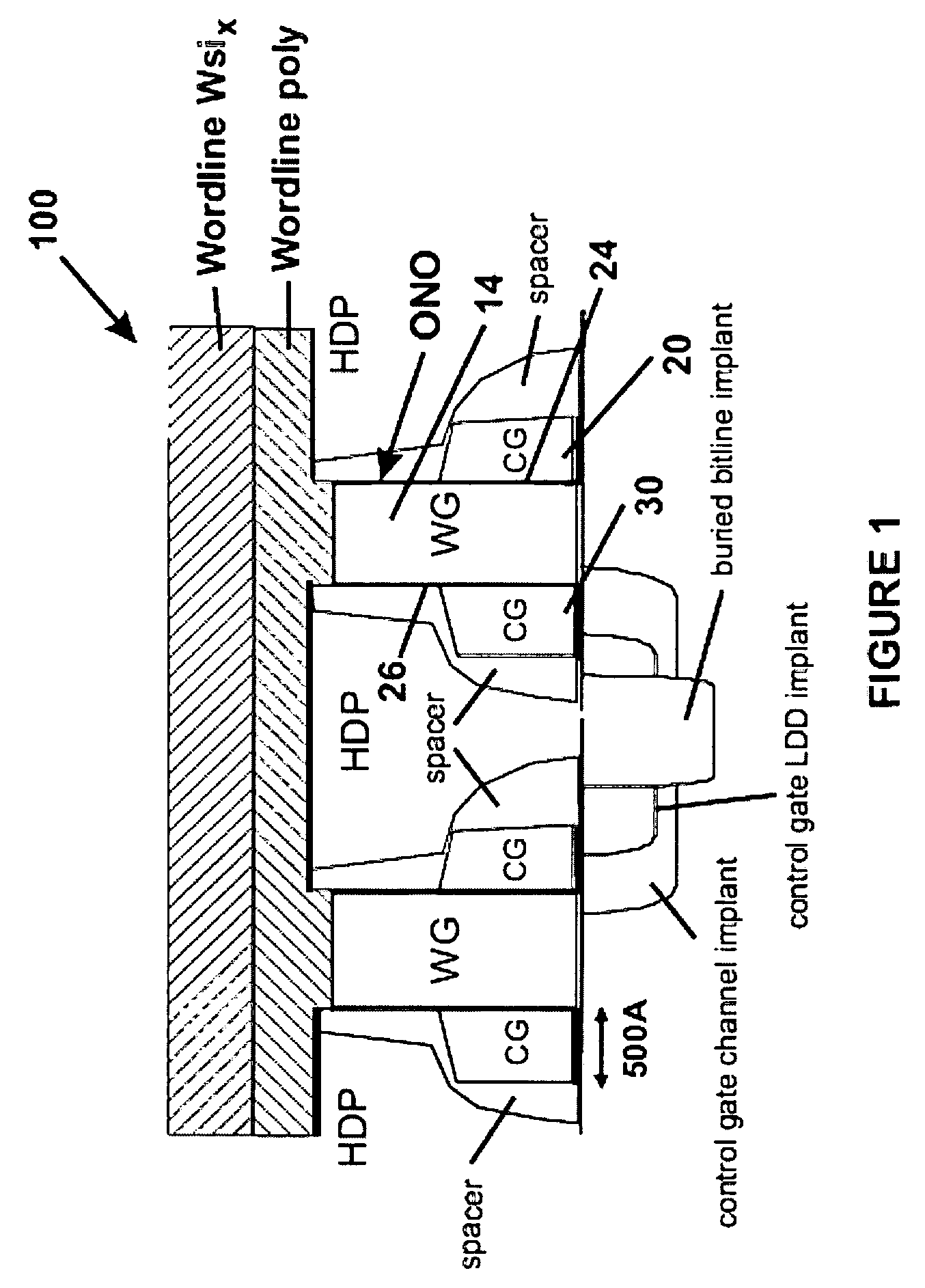

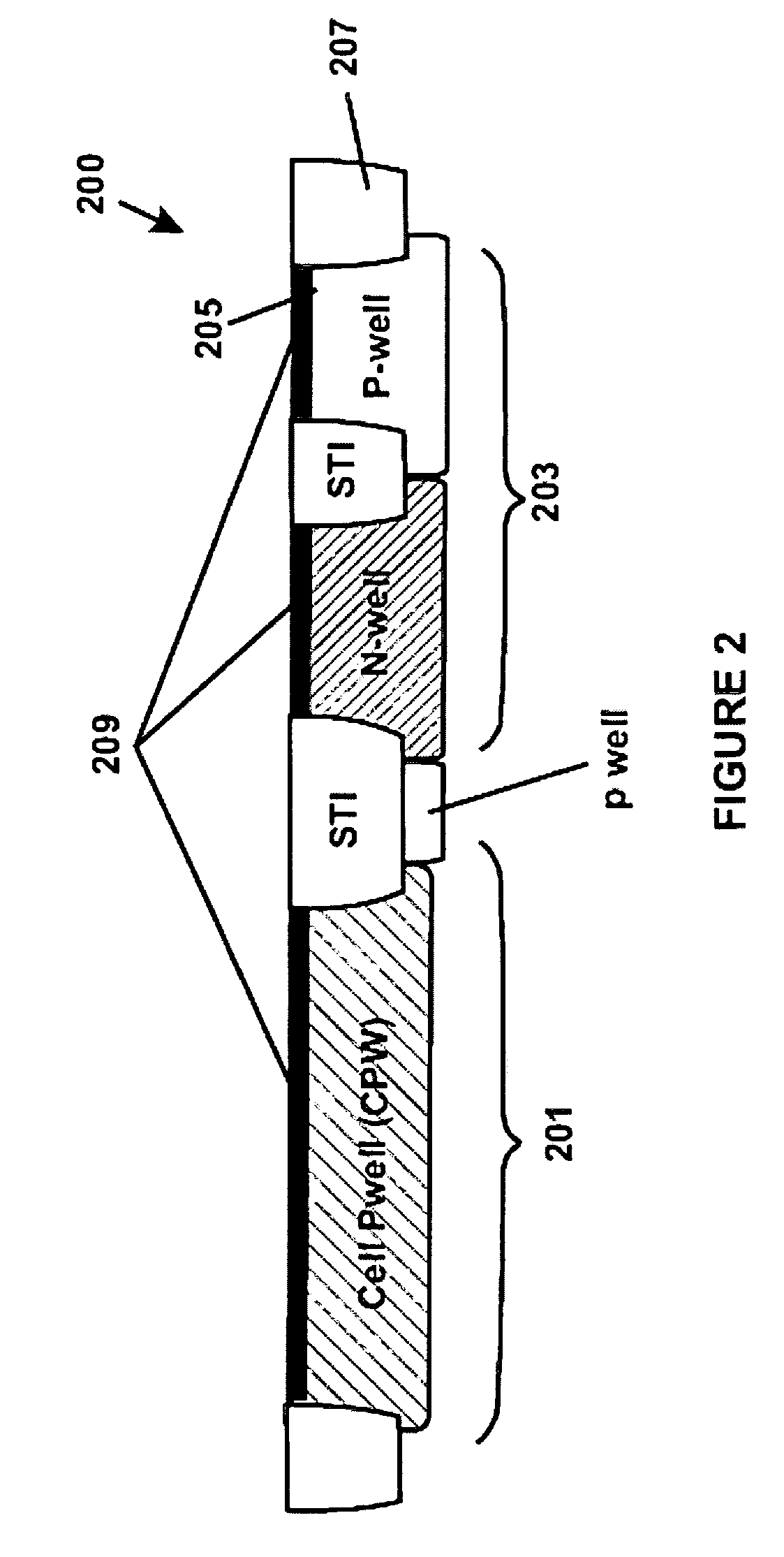

[0013] (1) A fabrication process that forms

memory cell array first, while peripheral poly is protected by an oxide layer to protect peripheral poly from later word line (WL) etch. After word gate (WG) deposition in our present flow, cap oxide is used to protect peripheral poly against a later WL etch, which stops on oxide. In the

memory cell area, however, oxide is removed by a cell

mask. The word gate is thereafter formed after SiN layer is deposited. As mentioned before, during WG etch, the peripheral poly is protected. Such a memory first process provides an ability to develop and possibly optimize the memory cells first without affecting peripheral logic

transistor architecture.

[0014] (2) The buried

bit line (BL) formation uses a

high density plasma (HDP) oxide layer, and includes a reverse

mask to remove oxide on peripheral region, which has

logic circuitry. After WG formation, while peripheral poly has been protected, many processes including control gate (CG) channel

implant, oxide-on-

nitride (ONO) / CG poly deposit and etch, cell LDD, oxide spacer, and BL

implant are provided to make a functional

memory cell transistor. Afterward, oxide-fill in-between BLs is provided for isolation. As device dimension shrinks, a gap fill oxide

deposition process is needed to fill the narrow BL spacing. Preferably,

high density plasma oxide has been used. A reverse

mask is then employed to clear peripheral area oxide first before BL oxidation oxide chemical mechanical

polishing, commonly called CMP. Such approach provides an

advantage of shorter

process time, better

process control, and wider

process window, among other possible benefits. Chemical Mechanical

Polishing technology has certain oxide to SiN selectivity such that minor surface morphology (i.e.,

shallow trench isolation (STI) edge) may

pose a problem for complete oxide removal without additional wet process after CMP. By using this embodiment of the invention, the additional wet recess process after the word gate, CMP could be used to optimize BL oxide recess specifically. Such BL oxide recess is often important or even critical for preventing shortage between nodes (e.g., WL, CG, WG).

[0015] (3) Simultaneous

contact formation for WL, buried BL,

logic gate and logic S / D. A practical manufacturing contact scheme is often a challenge for the buried

diffusion BL cell architecture, since BL has been sealed by HDP oxide in a relatively early stage of the process and a relatively high contact

aspect ratio. According to a preferred embodiment of the present invention, we adopted the scheme to form four different contacts simultaneously, with a

single step. As shown below, four contacts includes WL (with biggest step high ), BL contact,

logic gate contact, and logic S / D contact( with deepest aspect ration (A.R.)). Simultaneous

contact formation often saves process steps and mask counts according to preferred embodiments.

[0016] As noted, numerous benefits may be achieved using the present invention over other techniques. For example, the present invention provides an efficient way to optimize the cell region structures independently from the peripheral region structures. The cell region structures will include the MONOS memory devices. The peripheral region structures will include logic transistors. In other embodiments, the invention may use convention process technology for efficiency and reliability. One or more of these benefits may be achieved depending upon the embodiment. These and other benefits are described throughout the present specification and more particularly below.

Login to View More

Login to View More  Login to View More

Login to View More