Electrospun electroactive polymers for regenerative medicine applications

a technology of electroactive polymers and regenerative medicine, applied in the field of electroactive polymers for regenerative medicine applications, can solve the problems of poor quality reparative tissue, hyaline cartilage formation, and failure to restore a normal articular surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

Fabrication Of Piezoelectric Tissue Engineering Scaffolds

[0051]The present invention makes use of fibers formed from a permanently piezoelectric poly(vinylidene fluoride trifluoroethylene) (PVDF-TrFE) copolymer. The PVDF-TrFE copolymer was fabricated into a nanofibrous scaffold using an electrospinning technique.

[0052]The electrospinning process is affected by varying the electric potential, flow rate, solution concentration, capillary-collector distance, diameter of the needle, and ambient parameters like temperature. PVDF-TrFE and PLLA were electrospun into fibers according to commonly used optimization procedures whereby porosity, surface area, fineness and uniformity, diameter of fibers, and the pattern thickness of the sheet could be manipulated. See, e.g., Greiner, A. et al Angew Chem. Int. Ed. Engl. 46: 5670 (2007).

[0053]The electrospinning setup used herein is described in U.S. patent application Ser. No. 11 / 291,701, which is incorporated herein by reference. It is comprised...

example 2

Characterization of the Electrospun PVDF-TrFE Fibers

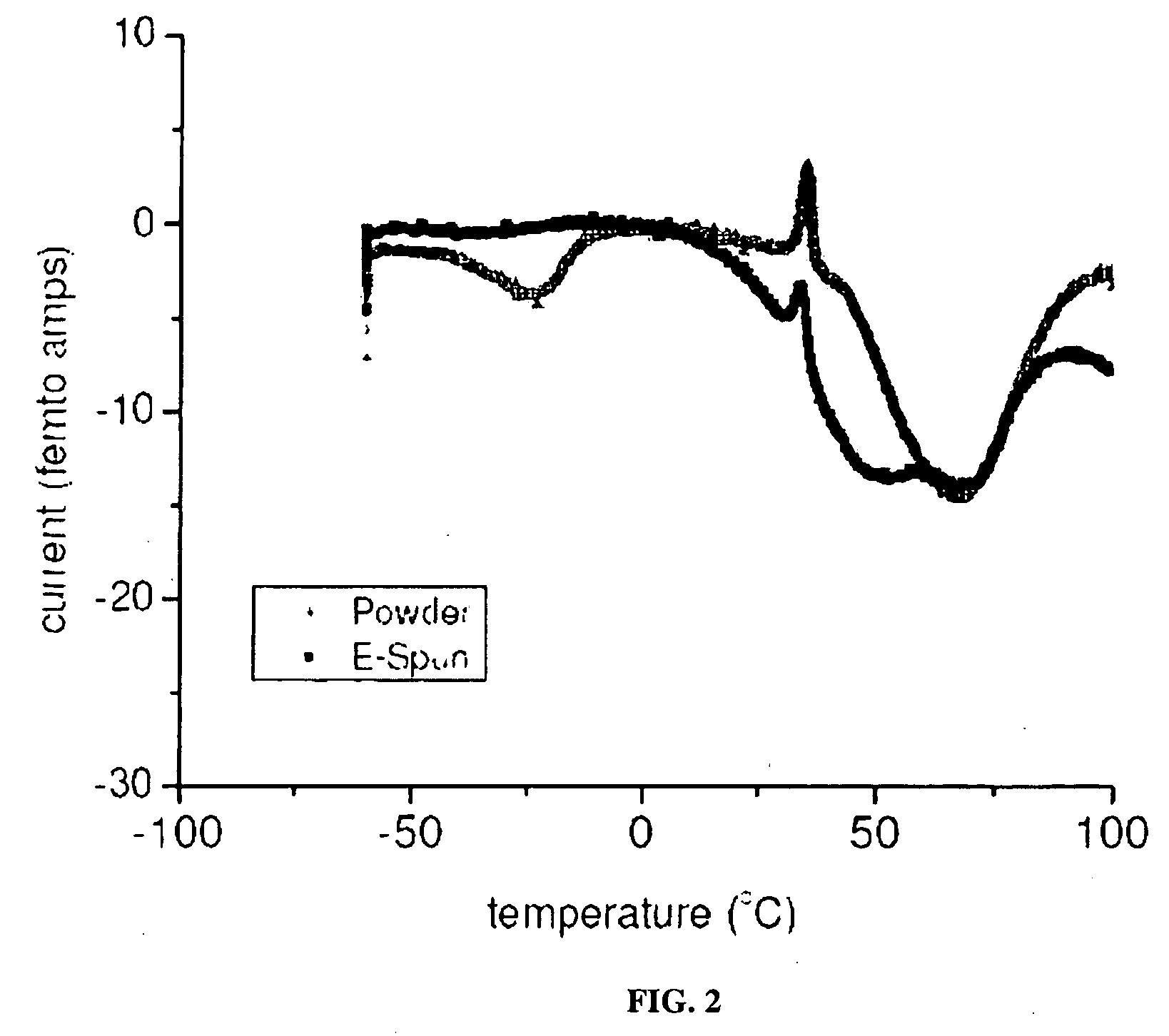

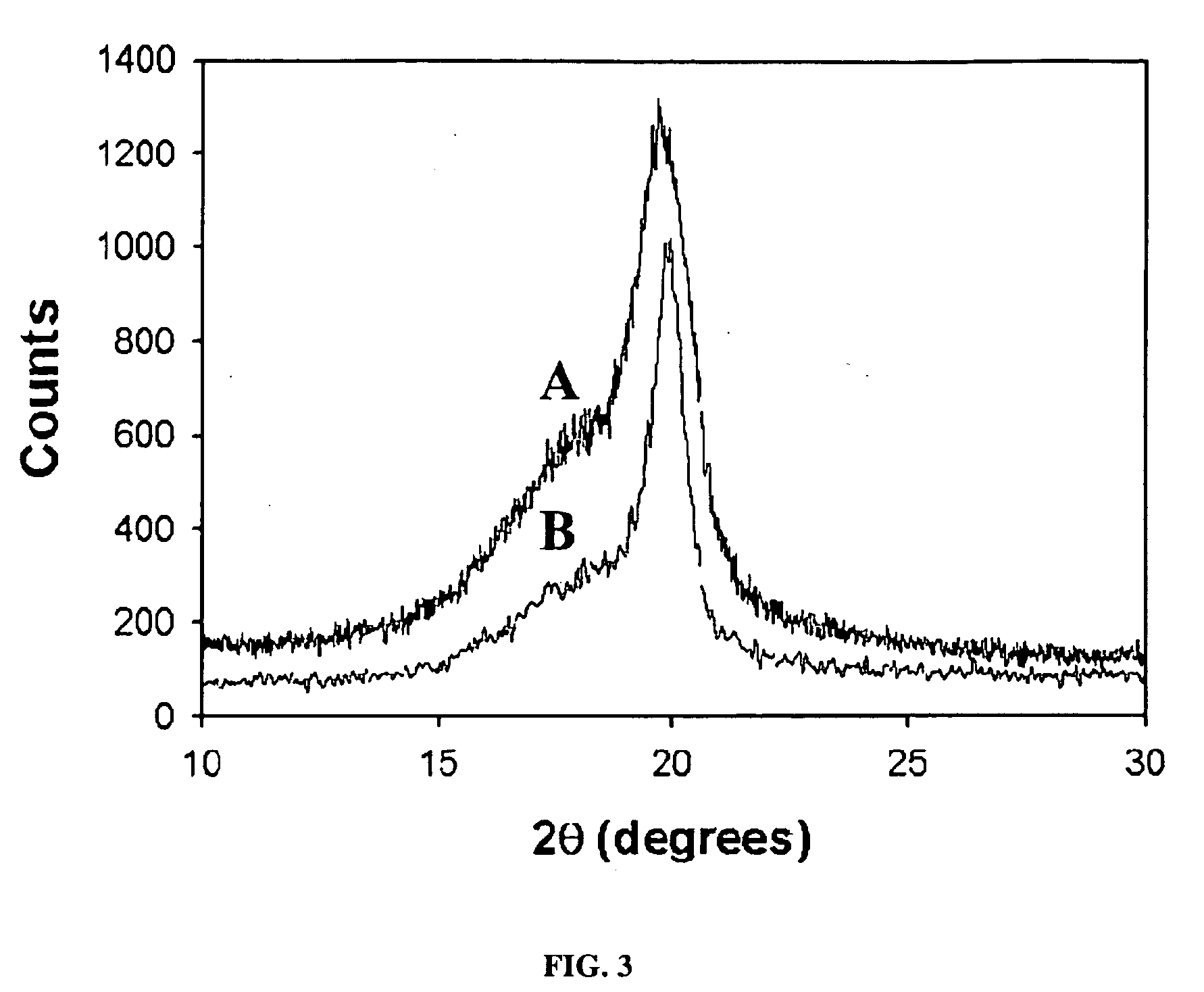

[0055]Structure and piezoelectric activity were examined by differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), thermally stimulated current (TSC) spectroscopy, X-ray diffraction (XRD) and fourier transform infrared spectroscopy (FTIR). Comparisons were made between PVDF-TrFE polymer powder and electrospun PVDF-TrFE fibers.

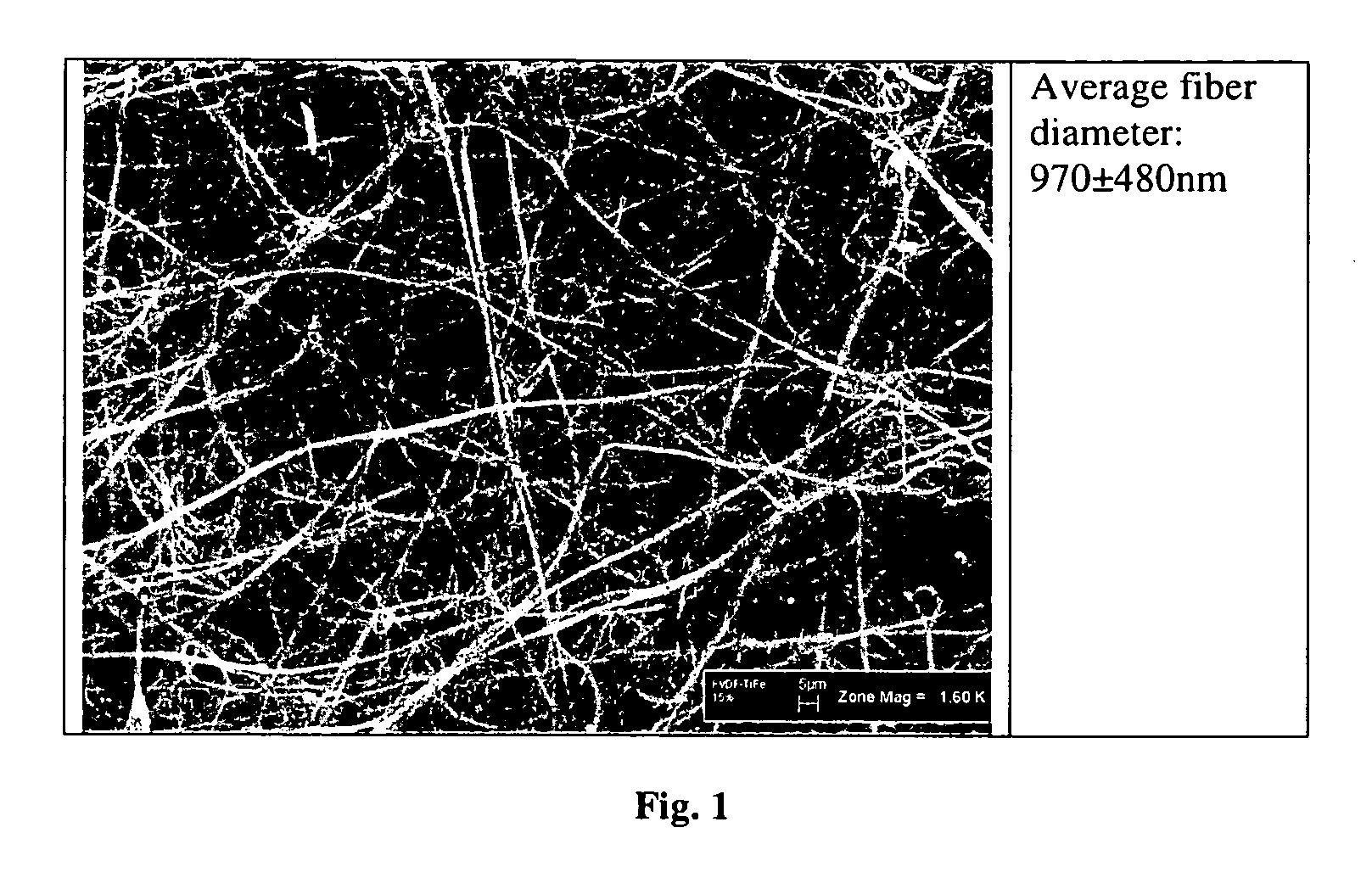

[0056]The fiber diameter of electrospun PVDF-TrFE fibers was characterized using Scanning Electron Microscopy (SEM) according to established methods and compared to poly L-lactic acid (PLLA) meshes. FIG. 1 shows that the resulting fibrous meshes had an average fiber diameter of 970±480 nm, with uniform fiber morphologies having no beading, as characterized by scanning electron microscopy. The fiber mats were free of droplets.

[0057]Thermally stimulated current (TSC) spectroscopy is widely used to understand dielectric relaxation in complex solid systems. TSC is based on the ability of polar ...

example 3

PVDF-TrFE Fiber Mats Support Stem Cells

[0071]Three studies were conducted to establish that the PVDF-TrFE fiber mesh can be used as a scaffold to support stem cells or other cell types

[0072]Materials and Methods

[0073]1. Cells

[0074](a) Cell line model for neuronal differentiation. When treated with nerve growth factor (NGF), PC12 cells, a cell line derived from a pheochromocytoma of the rat adrenal medulla, stop dividing, grow long neurites, and undergo terminal differentiation, which makes this cell line a useful model system for neuronal differentiation.

[0075]PC12 cells (ATCC number CRL-1721) were seeded at 3×103 cells per cm2 culture dish and maintained in ATCC formulated F-12K medium containing 1.5% fetal bovine serum and 15% horse serum. Cultures were maintained at 37 C, 95% air, 5% CO2 atmosphere. For induction of the neuronal phenotype, 50 ng / ml NGF (Chemicon) was added to the medium at the start of the culture and maintained throughout the duration of the culture. The term “i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Biocompatibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com