Pufa covered implants

a technology of metal implants and spherical layers, applied in the field of metal implants, can solve the problems of variation in the bond strength between the coating and the metallic substaret, affecting the success of the implant, and non-uniform layer thickness, so as to facilitate the control of hard and/or mineralized tissue adhesion, improve the adhesion of hard and/or mineralized tissue, and improve the effect of bone addition to the implant surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Matrix:

[0132]

TypeConcentrationof coinof EPATreatmentNo of coinsPolished 0 mMirradiated with UV lightin vitro 6 · 5 = 3010 mMno irradiationchar. 6 · 3 = 1850 mMGrit- 0 mMirradiated with UV lightin vitro 6 · 5 = 30blasted10 mMno irradiationchar. 6 · 3 = 1850 mMTotal number of coins96

Cleaning

[0133]1. Coins rinsed with pure water

2. Coins washed with ethanol

3. Ultrasonication of coins in water for 5 min

4. Again coins rinsed with pure water

5. Coins allowed to dry on sterile bench

6. Autoclaving of coins

[0134]1. Work in sterile bench

2. EPA solution is filtered (0.2 μm pore size) to sterilise it

3. 10 μl of respective solution of EPA in methanol is given on the surface of the coins

4. Coin is allowed to dry on sterile bench

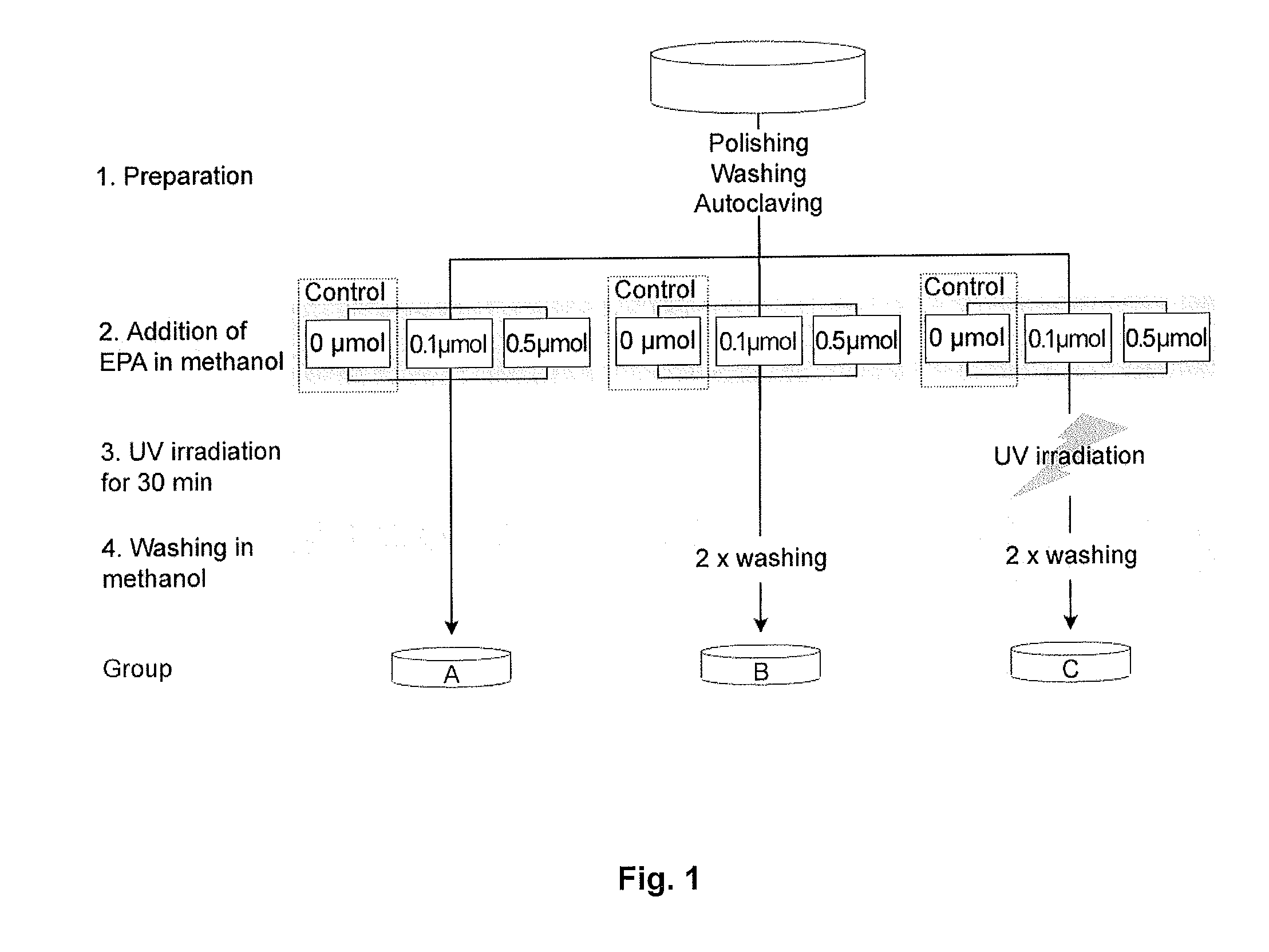

5. Part of the coins are irradiated with UV light after the solvent evaporated

→Fluo.link, λ=312 nm

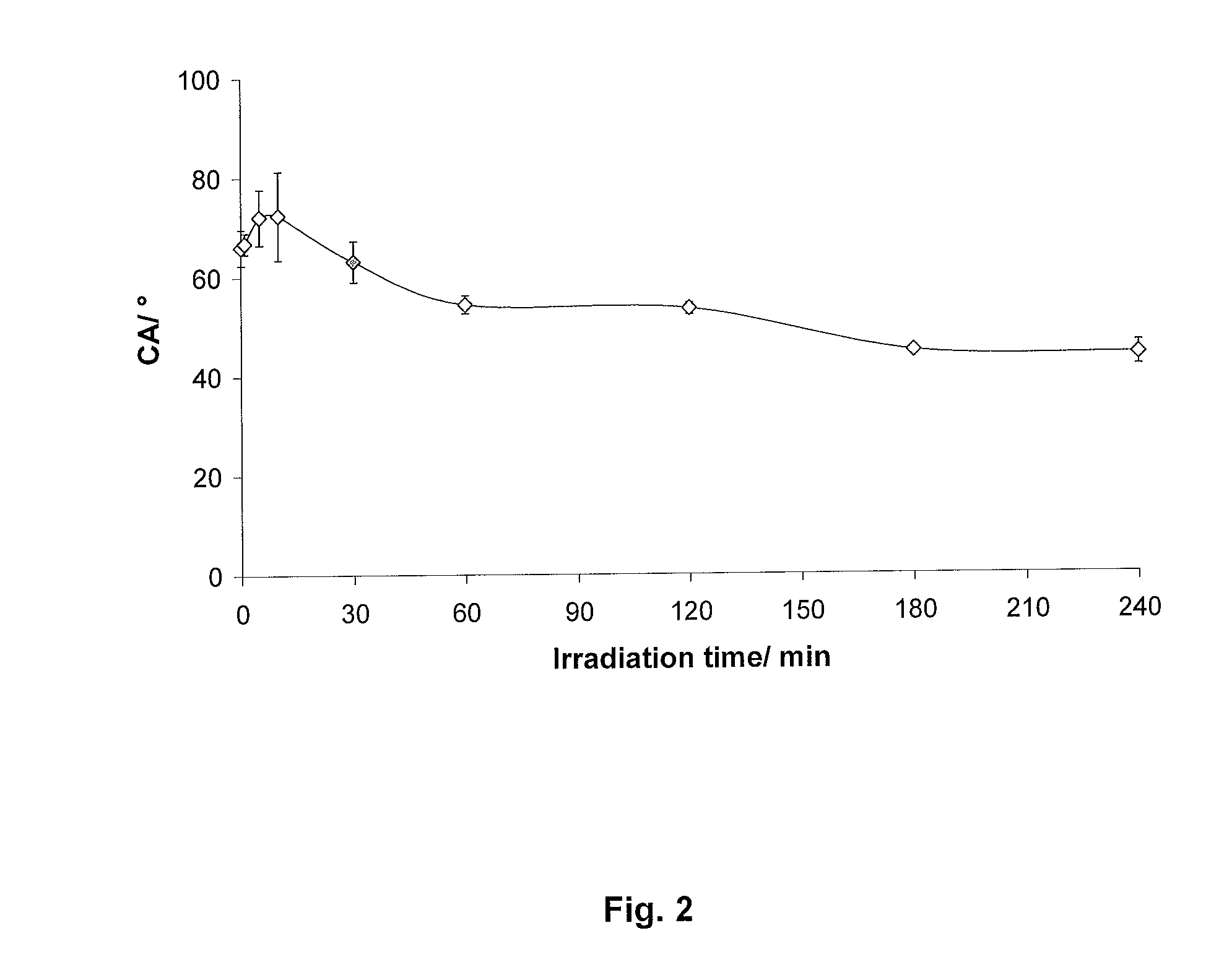

→Time of irradiation: 30 min (first test showed that the contact angle is increasing up to

10 min irradiation and decreases subsequently)...

example 2

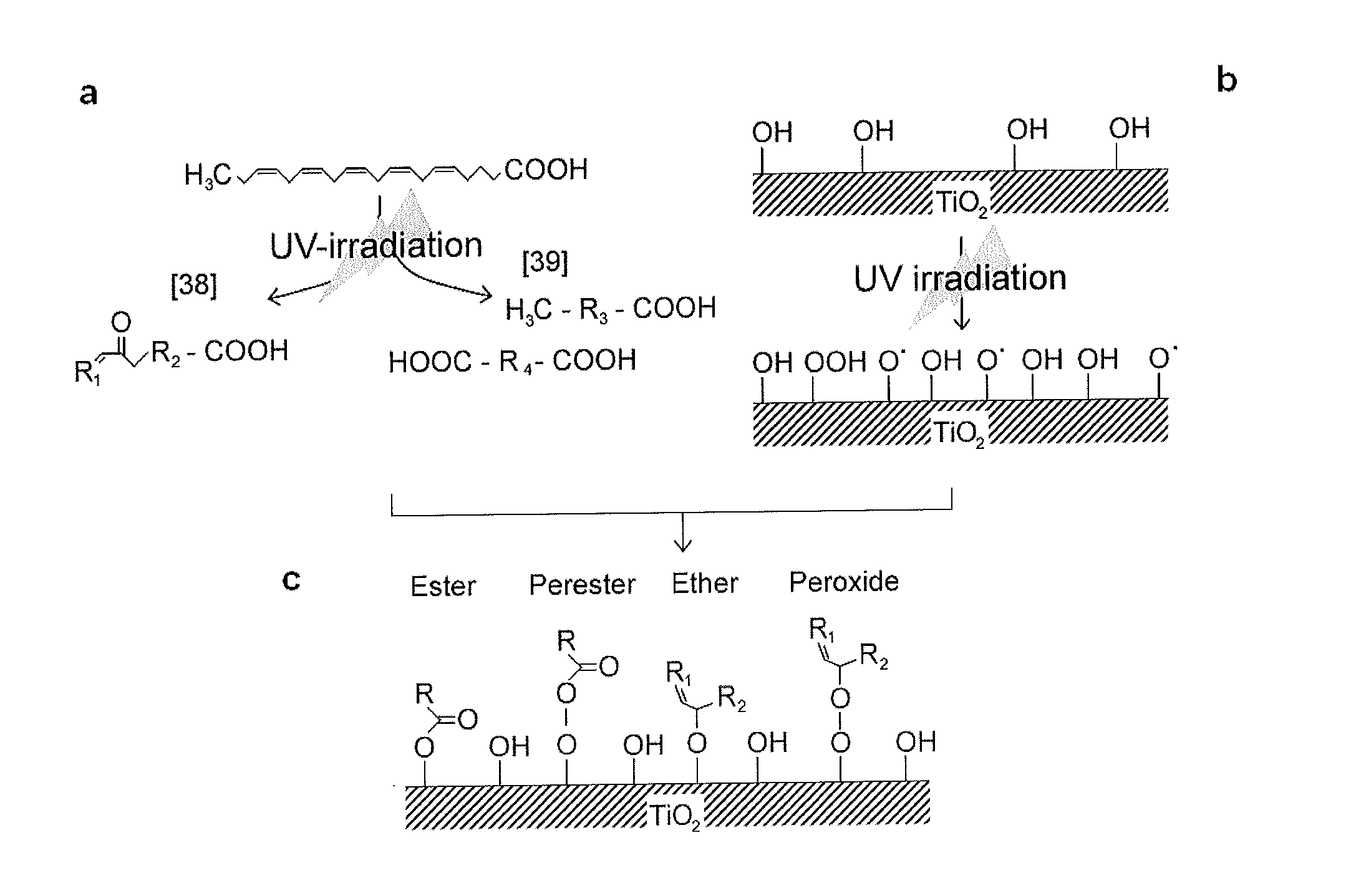

[0136]The aim of this study was to investigate the effect of EPA coating on Ti surface on osteoblast cell response in vitro. Methods to either physically adsorb or chemically bind the layer with EPA were compared, the latter one being produced by UV irradiation of TiO2 surfaces and EPA. Those surface coatings were detected and characterized by physical and chemical analytical methods. In vitro experiments were carried out to test cytotoxicity and ability of EPA-modified Ti surfaces to promote cell attachment and osteogenic differentiation of MC3T3-E1 cells.

Materials and Methods

Chemicals

[0137]EPA was purchased from Sigma (St. Louis, Mo., USA), radioactive labelled [14C]-EPA was obtained from American Radiolabeled Chemicals, Inc. (St. Louis, Mo., USA).

Titanium Implants and Treatments

[0138]Cp Ti implants with a diameter of 6.25 mm and a height of 2 mm were machined from cp Ti rods and subsequently grinded and polished (Phoenix 4000, Buehler GmbH, Düsseldorf, Germa...

example 3

[0176]Experiments performed in vivo with titanium implants containing a high dosage of physical adsorbed EPA and a low dosage of chemically-bound EPA.

Materials and Methods

Titanium Coins

[0177]Commercially pure (cp) machined titanium implants with a diameter of 6.25 mm and a height of 1.95 mm were cleaned and sterilized before use. Briefly, implants were washed together in a glass beaker with deionised water for 30 s, then with 70% ethanol for 30 s, and then with ultrasonic bath at 40° C. for 5 min in deionised water. The implants were subsequently placed in 40% NaOH solution in a water bath of 40° C. for 10 min, sonicated in deionised water for 5 min, and then washed with deionised water until the pH reached 6. Afterwards the implants were sonicated in deionised water at 50° C. for 5 min, placed in 50% HNO3 solution at 50° C. for 10 min, and sonicated in deionised water for another 5 min. The implants were washed with deionised water until reached pH=6 and were stored in 70% ethanol....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com