Hardmask composition for forming resist underlayer film, process for producing a semiconductor integrated circuit device, and semiconductor integrated circuit device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

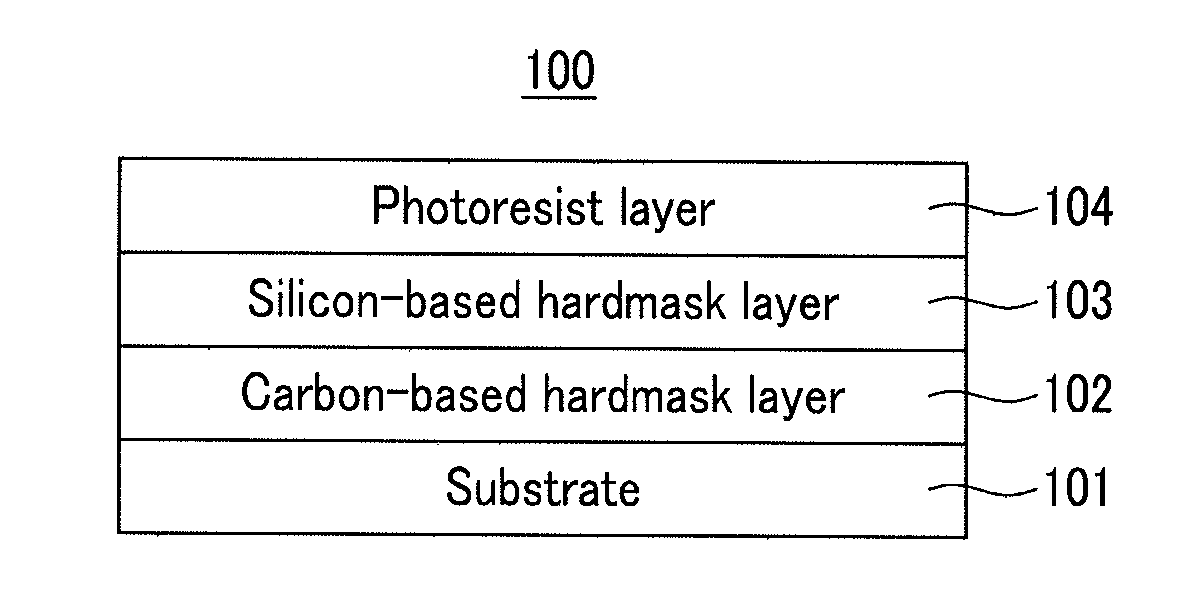

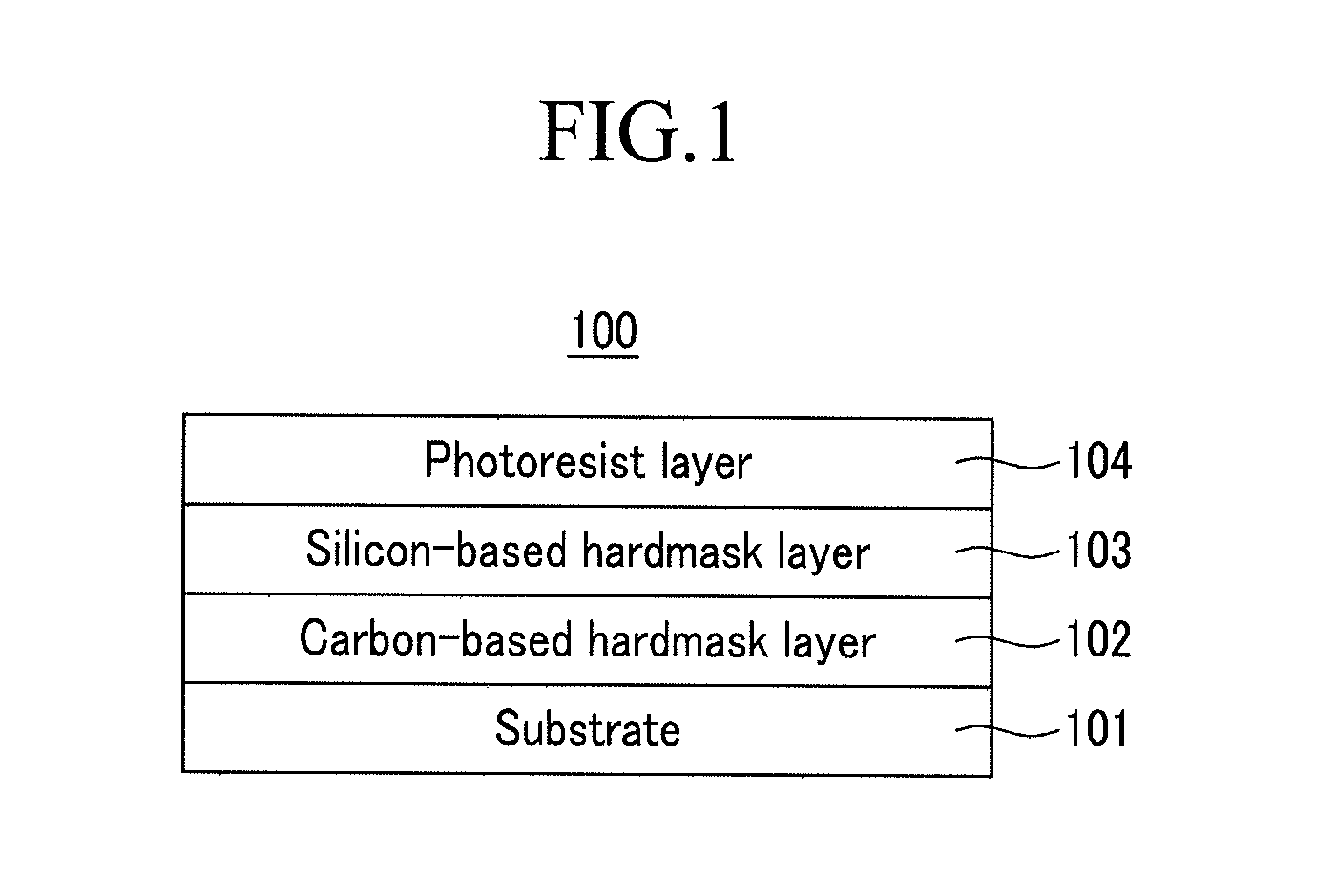

Image

Examples

example 1

[0096]1,750 g of methyltrimethoxysilane, 340 g of phenyltrimethoxysilane, and 313 g of trimethoxysilane were dissolved in 5,600 g of propylene glycol monomethyl ether acetate (PGMEA) in a 10-liter four-neck flask equipped with a mechanical agitator, a condenser, a dropping funnel, and a nitrogen inlet tube. To the solution was added 925 g of an aqueous nitric acid solution (1,000 ppm). After the mixture was allowed to react at 60° C. for 1 hour, methanol was removed from the reaction mixture under reduced pressure. The reaction was continued for 1 week while maintaining the reaction temperature at 50° C. After completion of the reaction, hexane was added to the reaction mixture to precipitate a polymer.

[0097]2.0 g of the polymer was diluted with 100 g of MIBK, and 0.002 g of pyridinium p-toluenesulfonate and 0.02 g of acetic anhydride were added thereto. A portion of the resulting solution was spin-coated on a silicon wafer coated with silicon nitride and a carbon-based hardmask, fo...

example 2

[0098]49.3 g of methyltrimethoxysilane, 43.9 g of phenyltrimethoxysilane, and 306.8 g of 1,2-bis(triethoxysilyl)ethane were dissolved in 1,600 g of propylene glycol monomethyl ether acetate (PGMEA) in a 3-liter four-neck flask equipped with a mechanical agitator, a condenser, a dropping funnel, and a nitrogen inlet tube. To the solution was added 131.3 g of an aqueous nitric acid solution (1,000 ppm). After the mixture was allowed to react at room temperature for 1 hour, alcohols were removed from the reaction mixture under reduced pressure. The reaction was continued for 1 week while maintaining the reaction temperature at 50° C. After completion of the reaction, hexane was added to the reaction mixture to precipitate a polymer.

[0099]2.0 g of the polymer was diluted with 100 g of MIBK, and 0.002 g of pyridinium p-toluenesulfonate and 10 g of propylene glycol propyl ether were added thereto. A portion of the resulting solution was spin-coated on a silicon wafer coated with silicon n...

example 3

[0100]220.1 g of methyltrimethoxysilane, 68.0 g of phenyltrimethoxysilane and 612.0 g of tetraethyl orthosilicate were dissolved in 2,100 g of propylene glycol monomethyl ether acetate (PGMEA) in a 5-liter four-neck flask equipped with a mechanical agitator, a condenser, a dropping funnel and a nitrogen inlet tube. To the solution was added 222.3 g of an aqueous nitric acid solution (1,000 ppm). After the mixture was allowed to react at room temperature for 5 hours, alcohols were removed from the reaction mixture under reduced pressure. The reaction was continued for 1 week while maintaining the reaction temperature at 50° C. After completion of the reaction, hexane was added to the reaction mixture to precipitate a polymer.

[0101]2.0 g of the polymer was diluted with 100 g of MIBK, and 0.002 g of pyridinium p-toluenesulfonate and 0.02 g of phenyltrimethoxysilane were added thereto. A portion of the resulting solution was spin-coated on a silicon wafer coated with silicon nitride and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com