Methods for fermenting carbohydrate-rich crops

a technology of carbohydrate-rich crops and methods, applied in the direction of fermentation, biofuels, etc., can solve the problems of 34° c temperature rise, high capital investment, and inability to cool the fermentation medium,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Infusion of Water into Sugar Beet Parenchyma Tissue

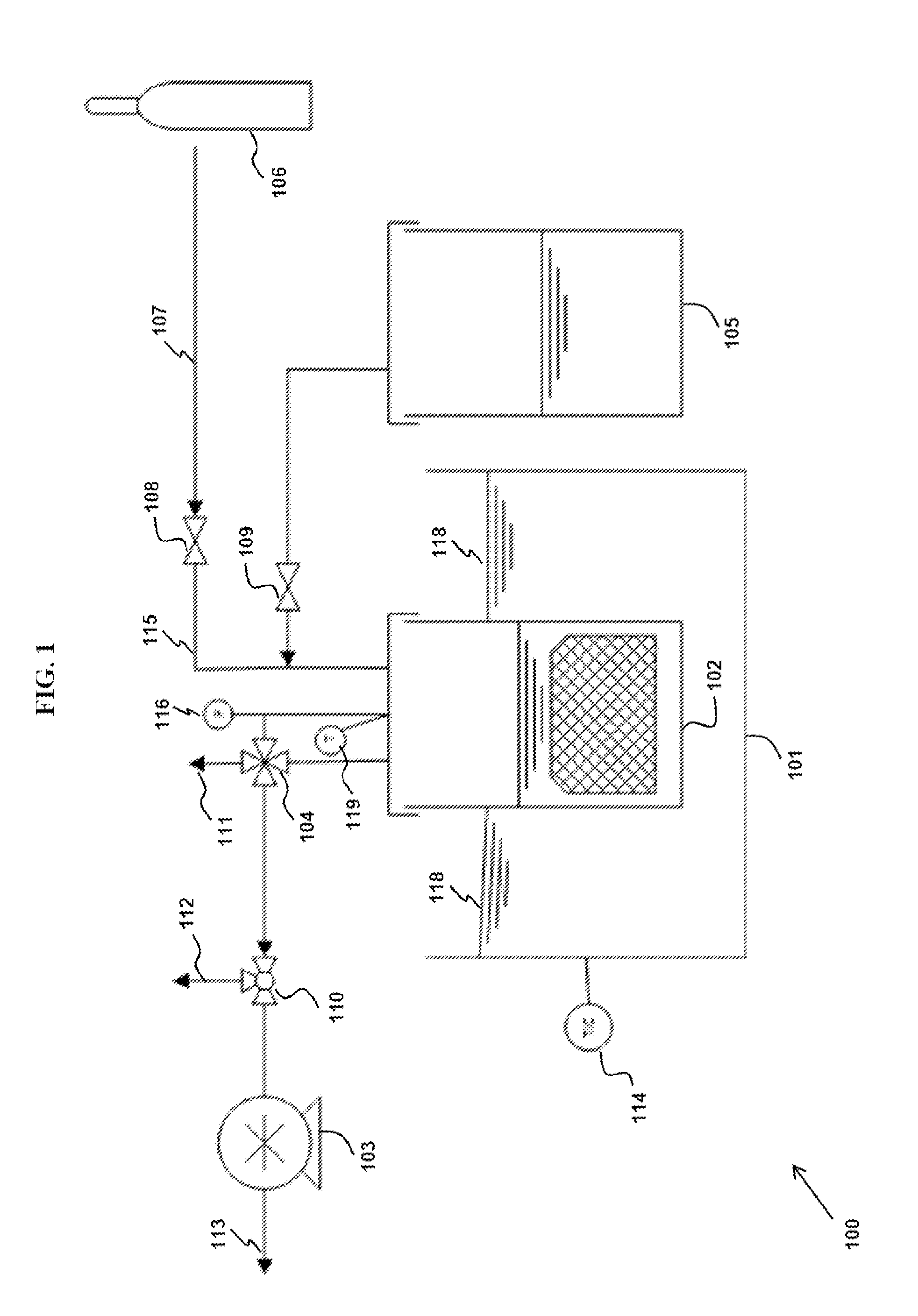

[0116]Slices of sugar beet were cut radially to three different thicknesses, 6 mm, 12 min and 18 mm. These slices were then cut into 25 mm square slices and all of the 25 mm square slices for each of the three thicknesses were weighed and put into three of the apparatus described above (FIG. 1). The gas cap was air for this example.

[0117]In Phase 1, a vacuum of 13 kPa was applied for 30 minutes, free water was removed, pressure was restored to 100 kPa and each cube was weighed.

[0118]In Phase 2, a vacuum of 13 kPa was applied for 30 minutes, water was infused under vacuum until the cube was covered, pressure was restored to 100 kPa, water infused into the parenchyma tissue for 30 minutes, free water was removed and then each cube was weighed.

[0119]In Phase 3, a vacuum of 13 kPa was applied for 30 minutes, free water was removed, pressure was restored to 100 kPa and each cube was weighed.

[0120]The result of this test are shown in Tabl...

example 2

[0121]Chopped sugar cane was infused with a slightly acidic yeast solution enriched with nitrogen-rich nutrients (Fermax from the BSG Corporation). Two different solutions were tested in duplicate, one using Thermosacc yeast and one using Distillamax yeast. Both yeasts are commercially available from Lallemand Biofuels & Distilled Spirits and differ in the average size of the cell bodies. The Thermosacc yeast has an average cell diameter of 5 microns and the Distillamax has an average cell diameter of 10 microns. After infusion was completed the carbon dioxide production was monitored through gas counters to estimate the fermentation progress. The following procedure was used:

[0122]1. Start heating thermostatic bath to 38° C.

[0123]2. Weigh approximately 50 g of sugar cane, then chop up into approximately one inch pieces, weighing the total amount of cane again after chopping.

[0124]3. Prepare two yeast solutions, one with 5 g / L Distillamax yeast, 1 g / L Ferma...

example 3

[0132]Coarsely chopped sugar beet pieces were infused with a slightly acidic yeast solution made Distillamax yeast by Lallemand Biofuels & Distilled Spirits. Different infusion times were used for each sample. After infusion was completed, the carbon dioxide production was monitored by the gas counters to estimate the fermentation progress. The following procedure was used:

[0133]1. Ensure that the thermostatic bath is at 38° C.

[0134]2. Weigh approximately 100 g of sugar beets, then chop up into pieces of approximately one-inch cubes, weighing the total beet again after chopping.

[0135]3. Prepare yeast solution with 5 g / L Distillamax yeast, buffering to a pH of 3.5 with phosphoric acid.

[0136]4. In the solution for samples 2 and 4 add an enzyme with pectinase activity at a loading of about 5 g per kg of dry biomass.

[0137]5. Place sugar beet sample in sealed beakers in the thermostatic bath, and apply vacuum for 30 min.

[0138]6. Infuse enough solution to submerg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com