Method for ceramization of aluminum alloy surface

a ceramization and aluminum alloy technology, applied in the field of aluminum alloy surface ceramization, can solve the problems of low-zone coating foaming, high cost, complex process and equipment, etc., and achieve good adsorption capacity, good elasticity, and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0018]1. Test Equipment

[0019]Heat, acid and alkali resistant plastic tank: 30 L; rectifier (oxidation power supply): 200A / 100V.

[0020]Plate: lead and lead-bismuth alloy plates; poles and wires: copper bars, copper wires

[0021]Material: aluminum alloy hub.

[0022]2. Dosing

[0023]1. Chromic acid and boric acid method (prepare 30 L solution)

[0024]Weigh 1120 g (40 g / L) of industrial-grade chromic anhydride and 84 g (3 g / L) of industrial-grade boric acid, dissolve into distilled water respectively, then add into a 30 L tank, and add distilled water to a prescribed volume for later use. In this method, the current density during electroplating process is 0.5-1.0 A / dm2.

[0025]2. Anodization and Anodization Post-Treatment

[0026]Heat with a heater, stir with compressed-air and hang anode plates bilaterally for oxidation under stable voltage, and fill with distilled water of about 90° C. for 30-60 minutes after anodization.

[0027]3. Process Test and Results

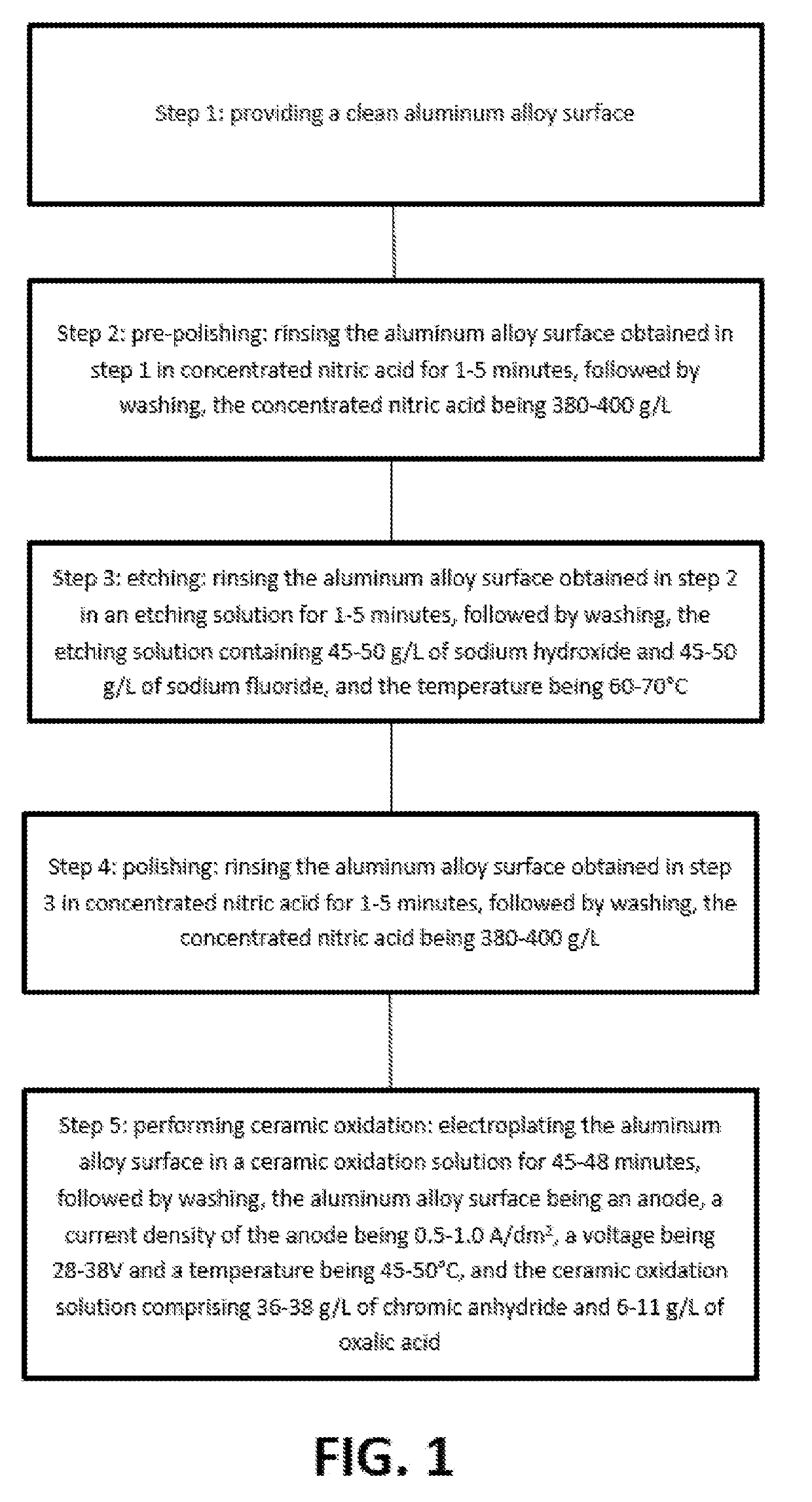

[0028]The method (FIG. 1) comprises the step...

embodiment 2

[0035]The method of this embodiment differs from Embodiment 1 in a step of rinsing the aluminum alloy surface under a high pressure water gun between steps 4 and 5, the water pressure of the high pressure water gun being 1360 Bar, and the rinsing time being 45 seconds.

[0036]In this embodiment, the following three dyeing conditions are taken:

[0037]A: dyeing at 28° C. for 7 minutes using a blue dyeing solution containing 30 g / L of potassium ferrocyanide and 40 g / L of potassium chloride.

[0038]B: dyeing at 28° C. for 7 minutes using a black dyeing solution containing 75 g / L of cobalt acetate and 22 g / L of potassium permanganate.

[0039]C: dyeing at 28° C. for 7 minutes using a white dyeing solution containing 30 g / L of lead acetate and 30 g / L of sodium sulfate.

embodiment 3

[0040]In this embodiment, the six surfaces obtained in Embodiments 1 and 2 were subjected to a copper accelerated acetic acid spray test respectively. The test was carried out in accordance with the methods described in GMW 14458:2011 (General Motors Worldwide Copper-Accelerated Acetic Acid Salt Spray (CASS) Test) and GMW 14729:2012 (General Motors Worldwide High Humidity Test). The results of samples were evaluated after exposure for 250, 500, 1000, 1250 and 1500 hours, and the results were shown in Table 1. The experiment was carried out in (SF2000SF2000SF2000)7# salt spray test chamber salt, and the test was completed by the Test Center of CITIC Daika Co., Ltd.

[0041]It can be seen from Table 1 that all the surfaces passed the CASS test of 1250 hours after the high pressure rinsing step was introduced in Embodiment 2, and had better protection capability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com