Tubular pecvd device for bifacial perc solar cell

a solar cell and tube-type technology, applied in the field of solar cells, can solve the problems of limited photoelectric conversion efficiency of the battery, less than ideal passivation effect of the film, low uptime, etc., and achieve the effect of improving the photoelectric conversion efficiency of the solar cell, reducing production costs, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

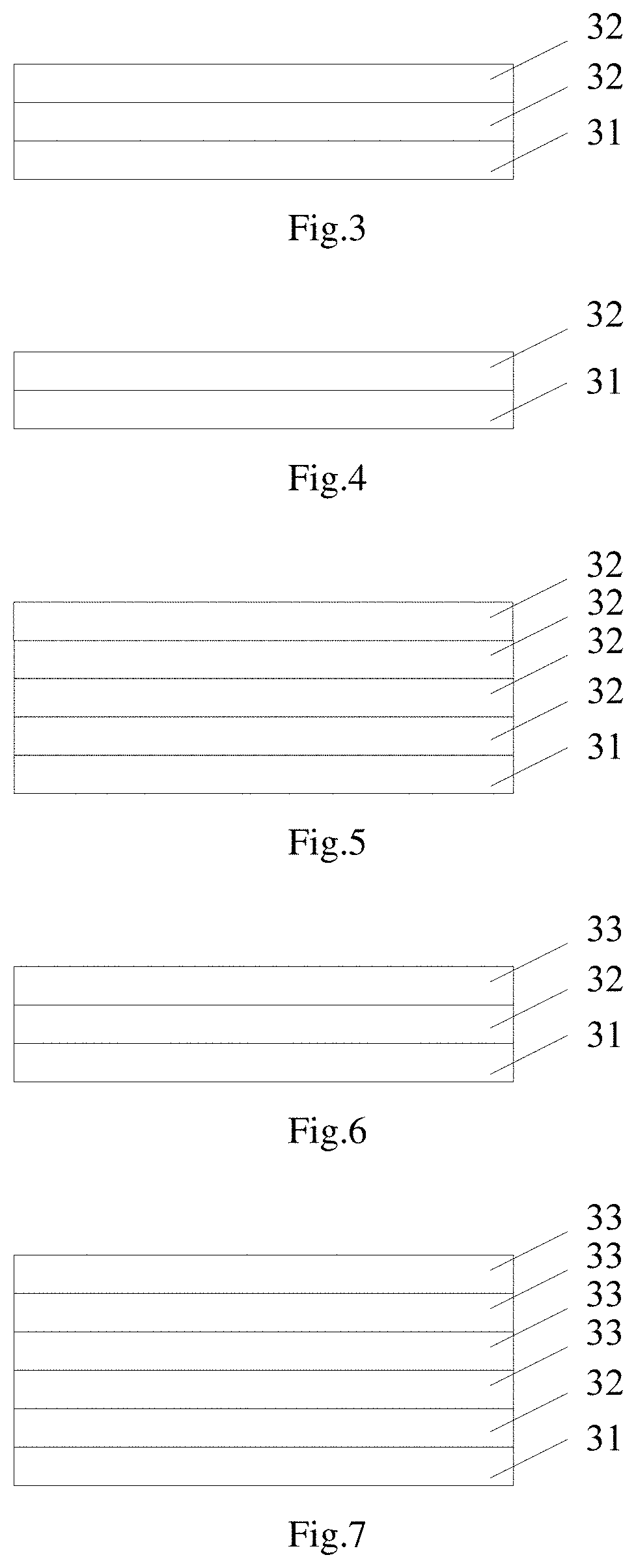

[0090]In the rear surface composite film shown in FIG. 3, the bottom layer 31 of the rear surface composite film 3 is an aluminum oxide film; the top layer 32 of the rear surface composite film is composed of a silicon oxynitride film and a silicon nitride film.

second embodiment

[0091]In the rear surface composite film shown in FIG. 4, the bottom layer 31 of the rear surface composite film is an aluminum oxide film; the top layer 32 of the rear surface composite film is a silicon nitride film.

third embodiment

[0092]In the rear surface composite film shown in FIG. 5, the bottom layer 31 of the rear surface composite film is an aluminum oxide film; the top layer 32 of the rear surface composite film is composed of a silicon dioxide film, a silicon oxynitride film A, a silicon oxynitride film B, and a silicon nitride film.

[0093]Referring to FIGS. 6, 7, and 8, the bottom layer 31 of the rear surface composite film is a silicon dioxide film; the middle layer 32 of the rear surface composite film is an aluminum oxide film; the top layer 33 is composed of one or more films selected from the group consisting of a silicon dioxide film, a silicon oxynitride film, and a silicon nitride film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle of inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com