Pressurized internal circulating fluidized-bed boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(First embodiment)

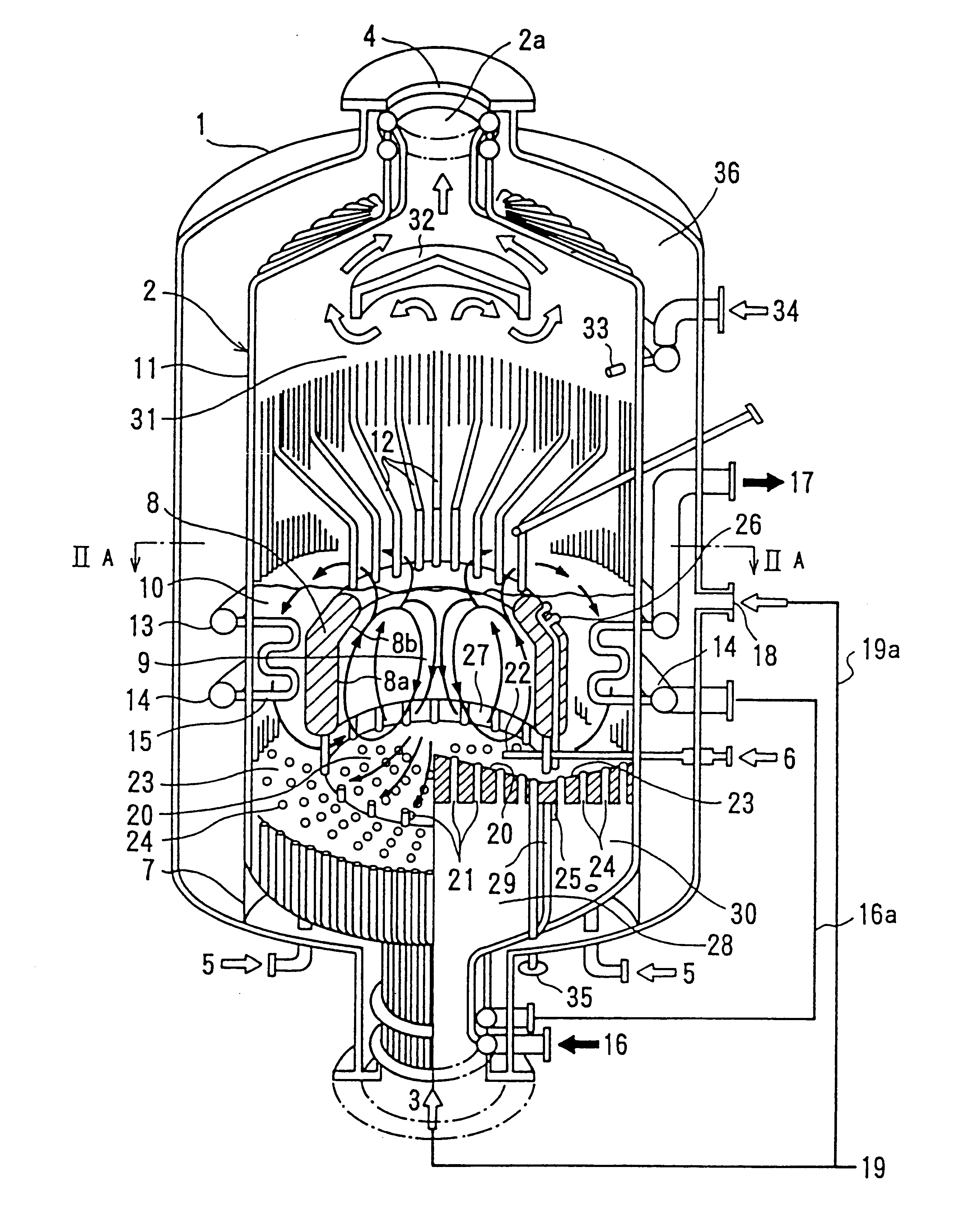

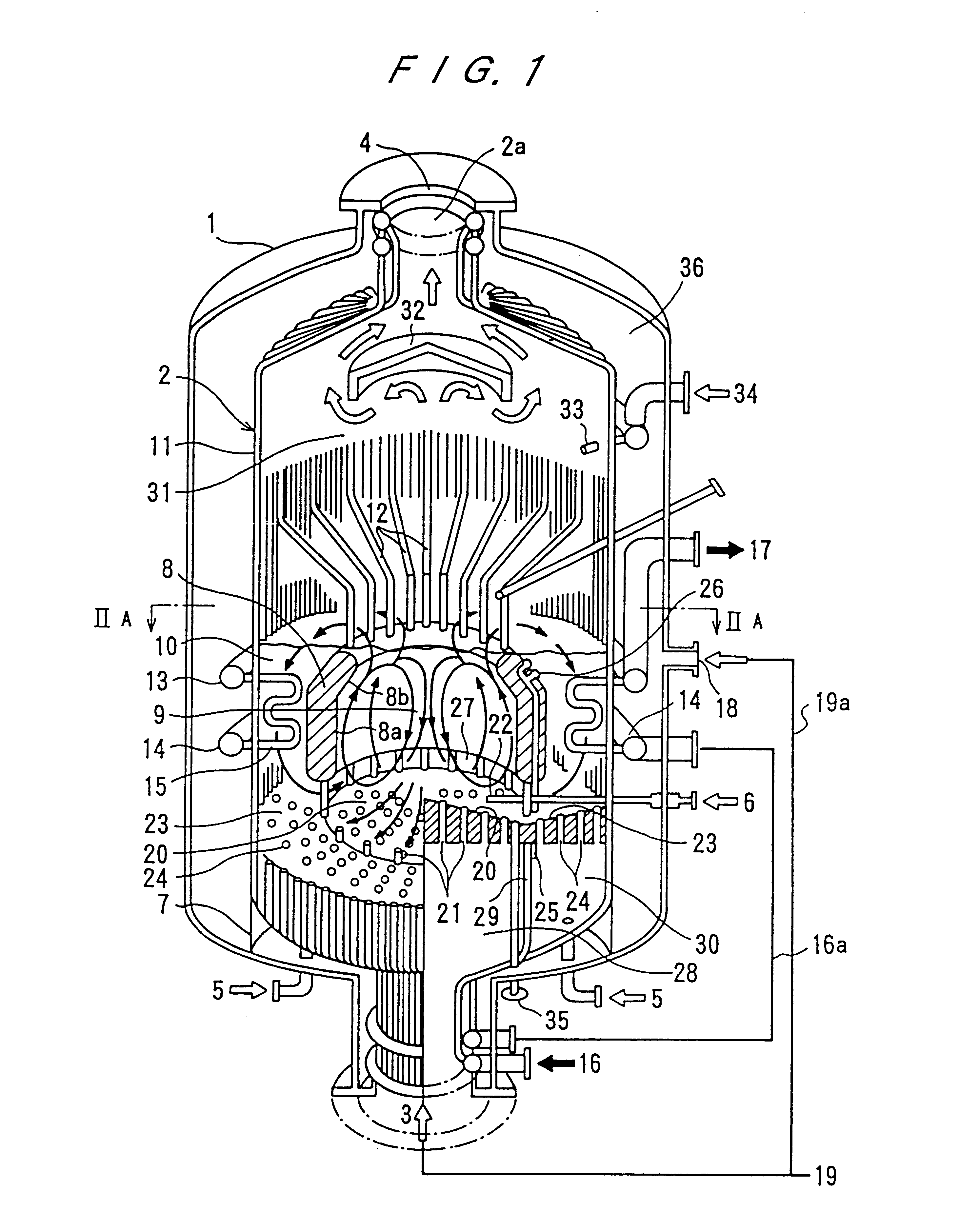

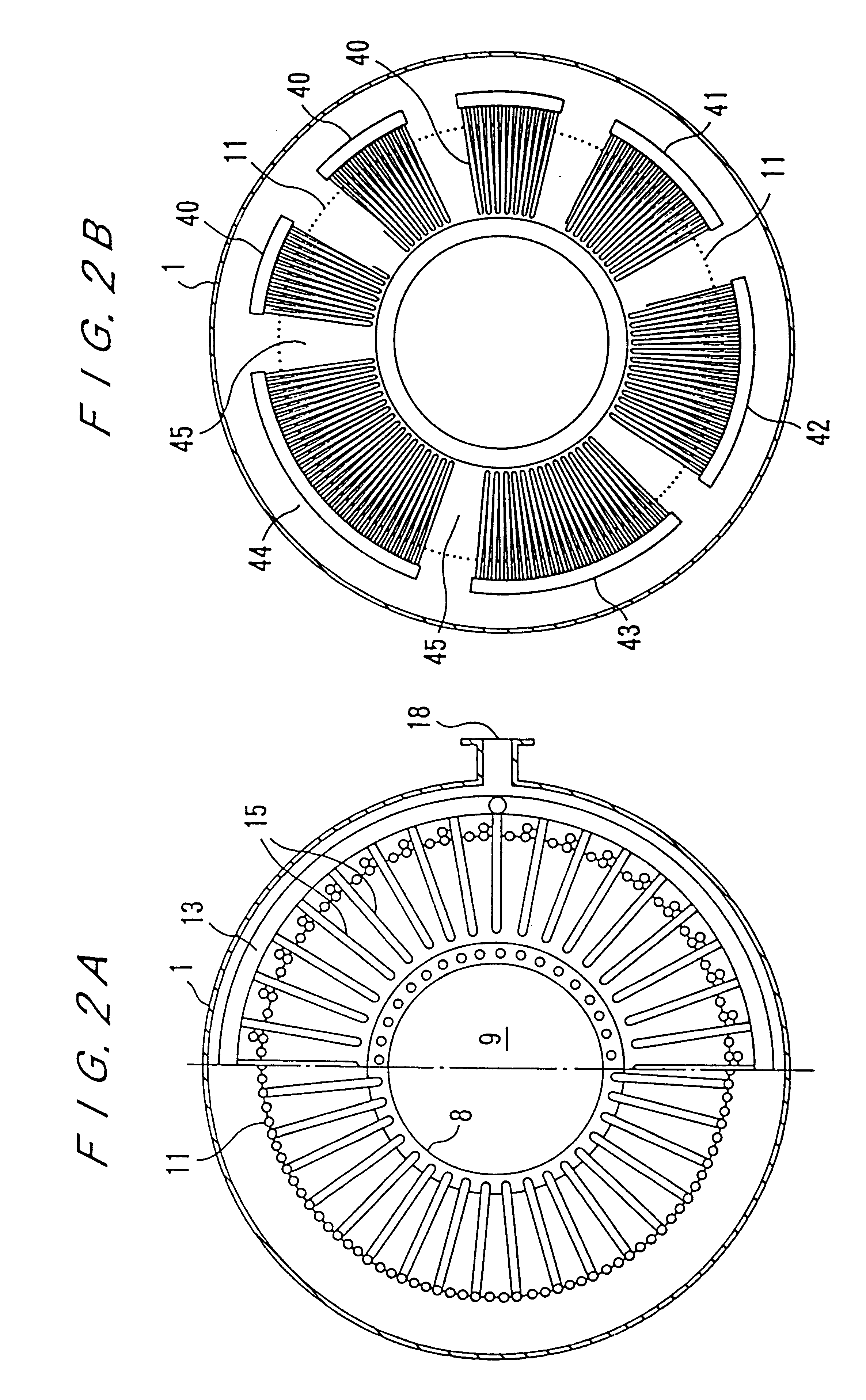

As shown in FIG. 1, the combined-cycle electric generating system includes a pressure vessel 1 which is of a cylindrical receptacle-like structure. The pressure vessel 1 is provided with a combustion gas outlet 4 at the top, a fluidizing air inlet 3 and thermal energy recovery chamber control air inlets 5 at the bottom. The pressure vessel 1 is constructed in such a way that it can retain higher inner pressure than atmospheric pressure. The pressure vessel 1 may be of a spherical body.

Inside the pressure vessel 1, there is provided a cylindrical combustor 2 which is an air tight vessel having a cylindrical membrane wall 11 consisting of water tubes. A main fluidized bed combustion chamber 9 is formed inside the cylindrical combustor 2. On the top of the cylindrical combustor 2, there is provided a combustion gas outlet 2a which is connected to the combustion gas outlet 4 of the pressure vessel 1. The cylindrical combustor 2 is firmly held to the bottom by a cylindr...

second embodiment

(Second embodiment)

FIG. 6 shows a system diagram of a combined-cycle electric generating system which incorporates a pressurized internal circulating fluidized-bed boiler according to a second embodiment of the present invention.

As shown in FIG. 6, an exhaust gas discharged from a pressure vessel 1 is introduced through an exhaust gas flow path 50 into a cyclone 51. Flying ashes collected by the cyclone 51 fall by gravity and are stored in a seal mechanism 52, from which they are carried by ash recycling 53 and returned to a thermal energy recovery chamber 10 through a recycled ash inlet pipe 54 that extends through side walls of a pressure vessel 1 and a cylindrical combustor 2.

Since flying ashes are recycled into the thermal energy recovery chamber 10, the average diameter and specific gravity of particles in the thermal energy recovery chamber 10 are reduced. While the average diameter of particles in the main combustion chamber 9 is about 0.6 mm, the diameter of particles which ...

third embodiment

(Third embodiment)

FIG. 7 illustrates a pressurized internal circulating fluidized-bed boiler according to a third embodiment of the present invention, the boiler including a system for processing an exhaust gas.

As shown in FIG. 7, flying ashes collected by a cyclone 51 in an exhaust gas flow path 50 are cooled by an ash cooler 77. A coolant used in the ash cooler 77 may be water supplied to the boiler or fluidizing air for effective recovery of the thermal energy from the ashes.

The cooled ashes are introduced through a lock hopper 78 into a classifying tank 79 in which they are mixed with flying ashes supplied from a dust collector 55 through an ash cooler 56 and a lock hopper 57, and the mixture is classified. In the illustrated embodiment, classifying air 80 is charged into the classifying tank 79 through an air diffuser pipe 81 for fluidized bed classification. However, this embodiment may not necessarily be limited to such type of classification.

Particles of unreacted desulfuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com