Silk brocade cloth dying method

A dyeing method and technology for real silk, applied in the field of dyeing, can solve problems such as unresearched and applied, difficult to control, and difficult to use, and achieve the effects of high dyeing efficiency, environmental protection, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

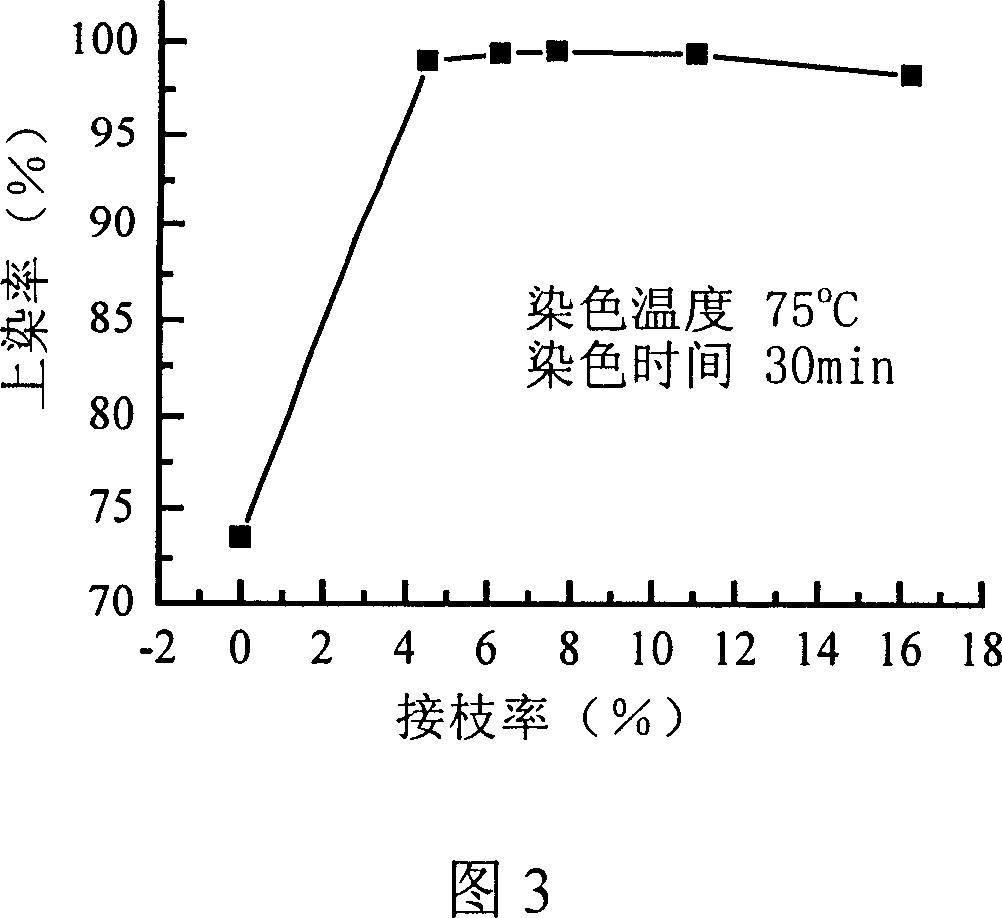

[0039] The grafting monomer is selected from ethyl methacrylate-2-(dimethylamine) ester (DMAEMAA), its concentration is 0.32mol / L, and the solvent is a mixed solution of ethanol and water (volume ratio is 4: 1). Dilute hydrochloric acid adjusts the pH value to 2, the padding (or dipping) bath ratio is: silk: solution=1: 40, the padding (or dipping) rate: 100 ± 2%; the ultraviolet light irradiation time is 20 minutes, obtains The grafting rate of real silk is about 6.5%.

Embodiment 2

[0041] The pH value of the grafting monomer solution was adjusted to 4, and the rest was the same as in Example 1, and the grafting rate of silk was about 8.6%.

Embodiment 3

[0043] The pH value of the grafting monomer solution was adjusted to 7, and the remainder was the same as that in Example 1, and the grafting rate of real silk was about 9.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com