Ultrahigh-molecular ethylene polymer

An ethylene polymer and ultra-high molecular weight technology, which is applied in the field of producing the ultra-high molecular weight ethylene polymer, can solve the problems of incomplete utilization of properties, residues, weak physical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

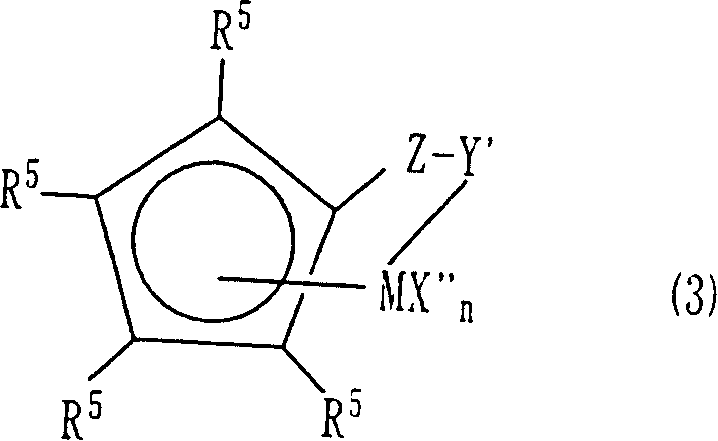

Method used

Image

Examples

Embodiment 1-9 and comparative example 1-4

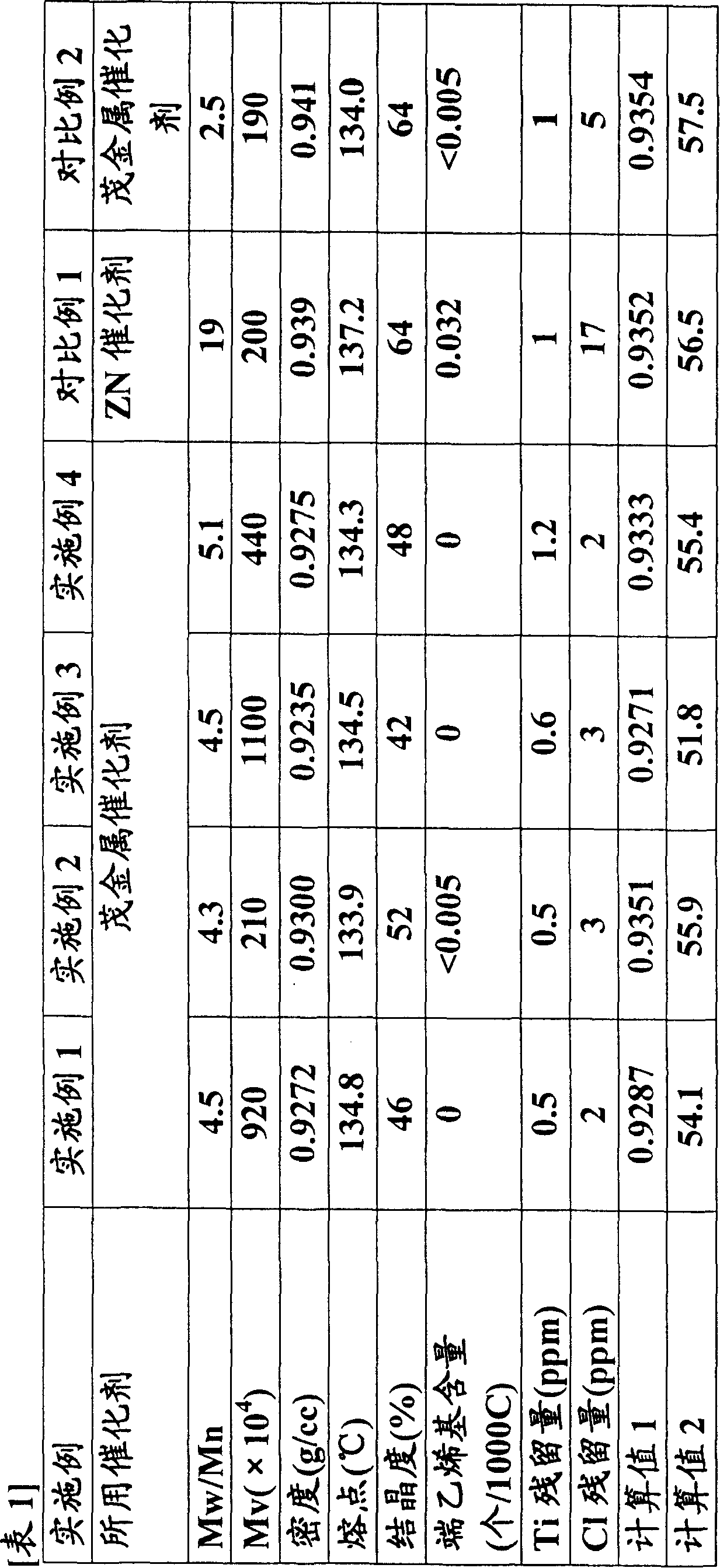

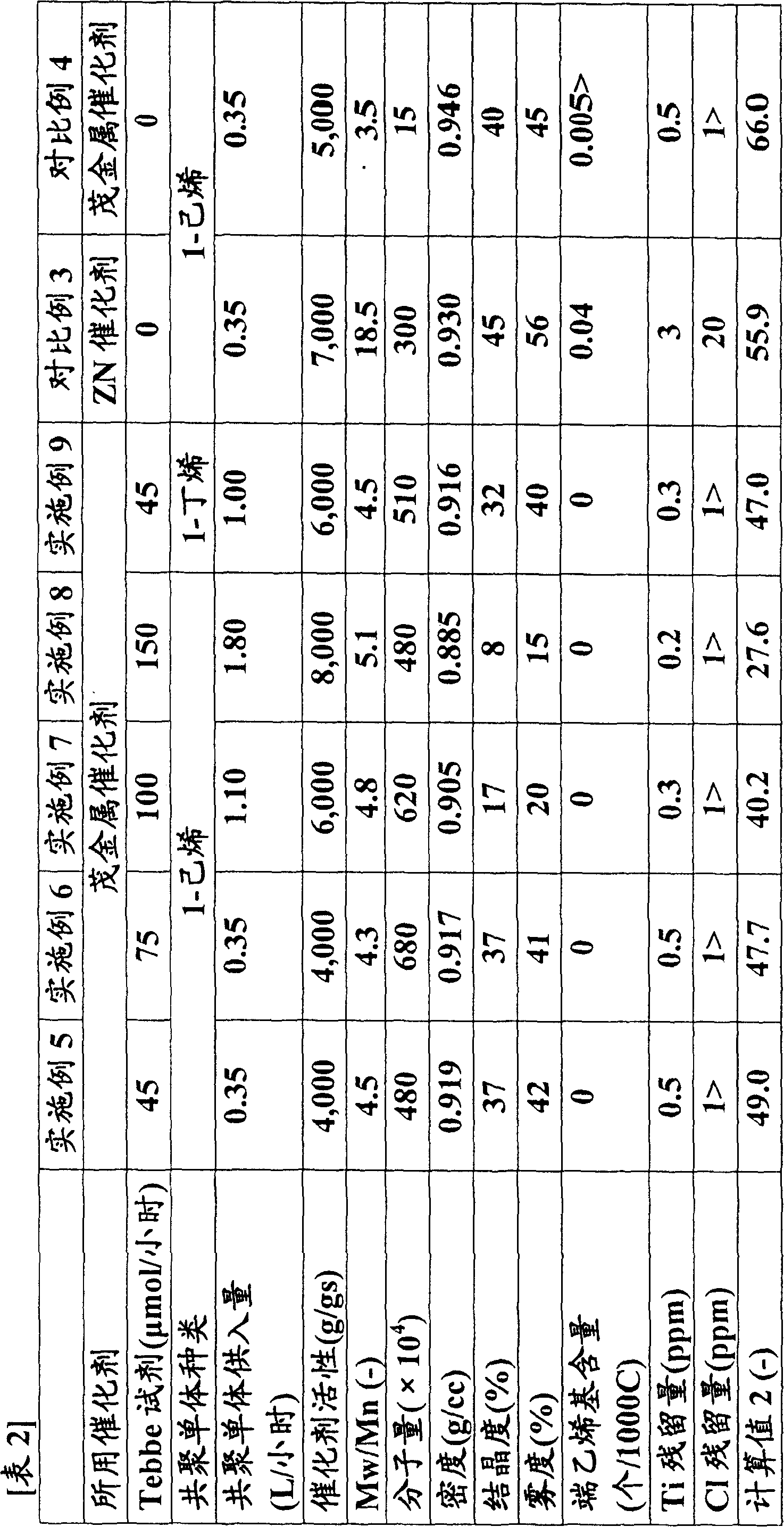

[0253] The present invention is described in detail below with reference to Examples and Comparative Examples. The present invention is by no means limited by these Examples. The measurement methods used in Examples and Comparative Examples are as follows.

[0254] [Measurement of Mw / Mn]

[0255] Using a 150-CA LC / GPC device (Waters Corporation), ShodexAT-807S (purchased from Showa Denko K.K.) and TSK-gel GMH-H16 (purchased from Tosoh Corporation) were used as columns in series, and a three-phase column containing 10 ppm IRGANOX1010 (Ciba Specialty Chemicals) was used. Chlorobenzene was used as solvent and measurements were carried out at 140 °C. A commercially available monodisperse polystyrene was used as a reference material to generate a calibration curve.

[0256] [Measurement of viscosity average molecular weight]

[0257] 2 mg of the polymer was added to 20 ml of decalin, and stirred at 150° C. for 2 hours to dissolve the polymer. Use the Ubbelohde viscometer to meas...

Embodiment 1

[0279] (preparation of compound (D) with hydrogenation ability)

[0280] A 3% by weight hexane suspension containing 30 mmol titanocene dichloride (available from Wako Pure Chemical Industries, Ltd.) and 60 mmol 1M trimethylaluminum hexane solution was stirred at room temperature for 100 hours to prepare Tebbe's reagent.

[0281] (Polymerizing ethylene: Preparation of ethylene homopolymer (A))

[0282] Isobutane, ethylene, hydrogen, metallocene catalyst, and Tebbe's reagent were continuously fed into a vessel-type polymerization reactor equipped with a stirrer to produce polyethylene (ethylene homopolymer) at a productivity of 10 kg / Hr. Hydrogen purified to 99.99 mol % or higher by contact with molecular sieves is used. Using [(N-tert-butylamino) (tetramethyl-η 5 -cyclopentadienyl)dimethylsilyl]titanium-1,3-pentadiene, bis(hydrogenated tallow alkyl)methylammonium-tris(pentafluorophenyl)(4-hydroxyphenyl)boron A catalyst obtained by loading a mixture of triethylaluminum salt ...

Embodiment 2

[0284] Polymerization was performed in the same manner as in Example 1, except that Tebbe's reagent was fed at a rate of 0.013 mmol / hour. In this case, no bulk polymer was produced, nor was the slurry discharge pipe blocked, and stable continuous operation was achieved. The resulting polyethylene had an average molecular weight of 2,100,000 as determined by intrinsic viscosity (135° C.) in decalin, a density of 0.9300 g / cc and a crystallinity of 52%. The results of these and other measurements for this example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com