Bovine serum albumin hot ethanol extracting process

A technology of bovine serum albumin and extraction process, which is applied in the field of bovine serum albumin hot ethanol extraction process, can solve the problems of low production efficiency, time-consuming and labor-intensive, low yield of cold salting out method, and achieve easy mastery and process flow Short and economically significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

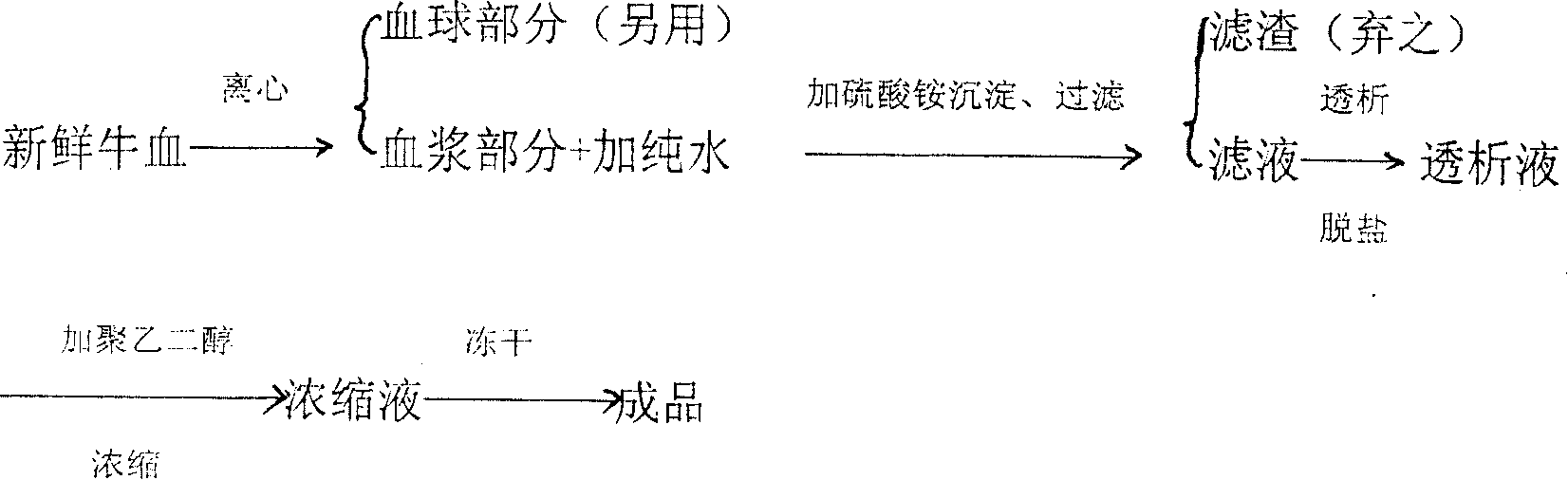

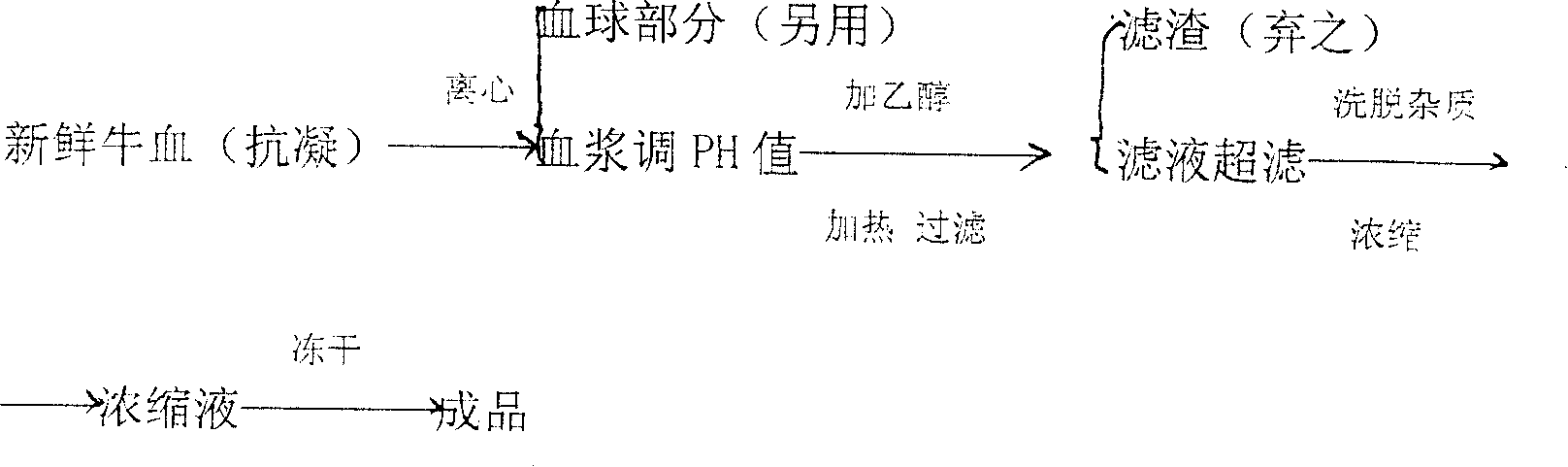

[0023] Technology of the present invention has the following steps:

[0024] A. To separate the plasma, take the fresh cattle blood from natural grazing cattle, go through strict quarantine to ensure that there is no infectious disease, put the blood into a centrifuge with refrigeration function, add 10% of the blood volume and 3.8% citron Sodium bicarbonate, centrifuge at 4000 rpm, temperature below 2°C, separate plasma and blood cells, collect plasma, and blood cells for another use;

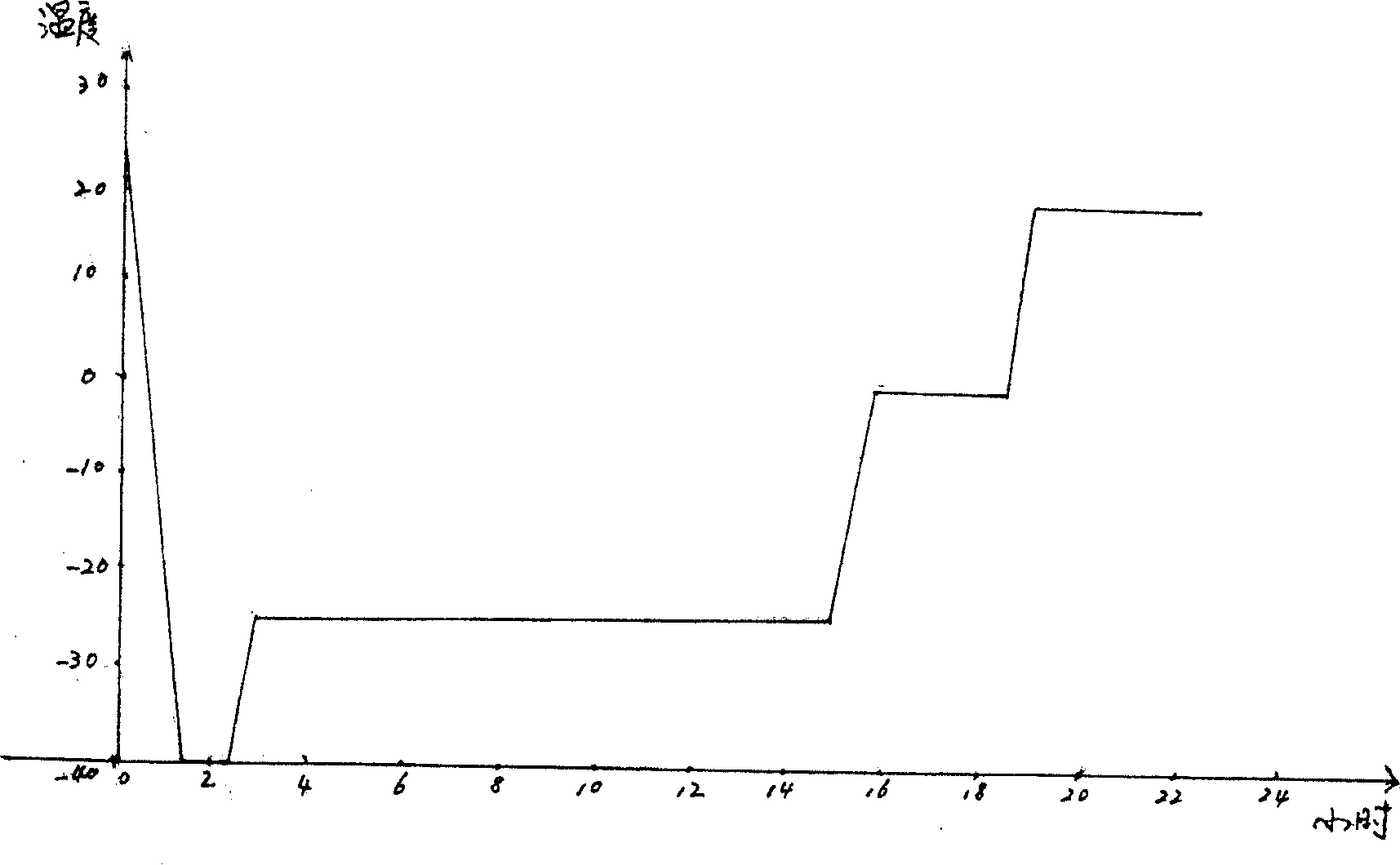

[0025] B. Extraction, put the plasma into the interlayer reaction tank, heat the water in the interlayer, add 0.2-0.3% sodium octanoate of bovine serum volume while heating, stir slowly, the temperature is 55 ° C ~ 60 ° C, adjust the pH value after dissolution , adding concentration of 1 mole of hydrochloric acid, the pH is adjusted to 6, then adding 5.5% of the total serum concentration of 95% ethanol, heating time is 25-40 minutes; then filter with canvas, and discard the filter residue;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com