Semi-dry microwave treating process of preparing galactomannan

A technology of galactomannan oligosaccharides and galactomannan, which is applied in the field of preparation of galactomannan oligosaccharides by semi-dry microwave treatment, can solve the problems of high energy consumption, low production efficiency, and many pollutants, and achieve refining efficiency High efficiency, improved production efficiency, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

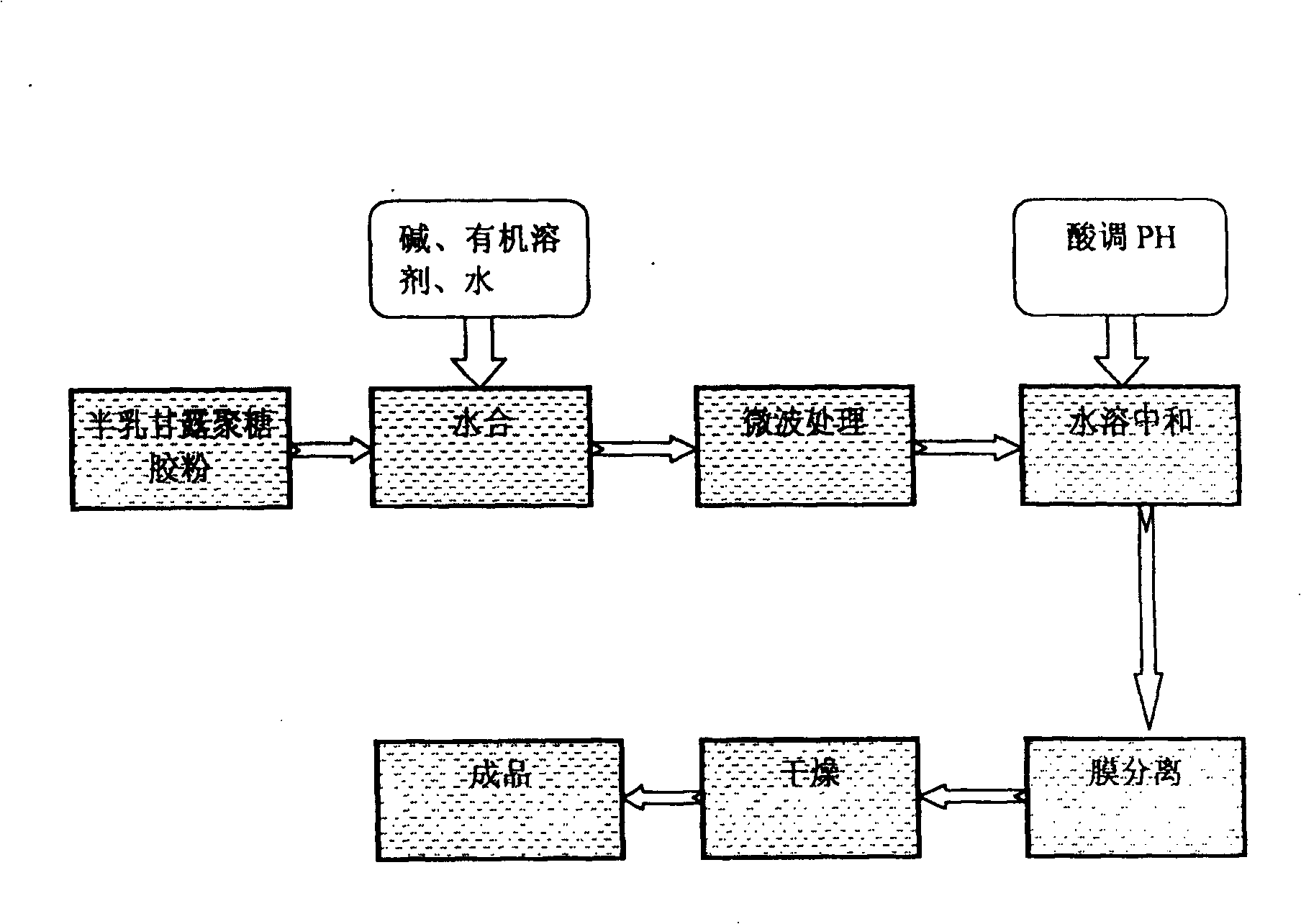

Method used

Image

Examples

Embodiment 1

[0029] 10kg of wild honey locust gum powder is added to stirring device, add 0.75kg sodium hydroxide, 1.5kg95% ethanol, 0.75kg water, stir for 45 minutes, semi-wet wild honey locust gum powder is placed in microwave drying equipment, adjust microwave power 750 watts, Treat for 25 minutes, dissolve the treated rubber powder in water to form a solution with a concentration of 15%, adjust the pH to 7.0 with citric acid, pass the solution through a hollow fiber membrane with a molecular weight cut-off of 2000 Daltons at room temperature, and work at a pressure of 0.12Mpa. The Acacia oligosaccharide solution passing through the membrane was spray-dried, and the spray drying outlet temperature was controlled at 85° C. to obtain 7.3 kg of white Acacia oligosaccharide powder.

Embodiment 2

[0031] Put 10kg of fenugreek powder into the stirring device, add 0.6kg of sodium hydroxide, 1.3kg of isopropanol, 0.7kg of water, stir for 35 minutes, put the semi-wet powder of fenugreek in the microwave drying equipment, adjust the microwave power 500 watts, treat for 15 minutes, dissolve the processed rubber powder in water to make a solution with a concentration of 12%, adjust the pH to 7.0 with hydrochloric acid, pass the solution through a hollow fiber membrane with a molecular weight cut-off of 2000 Daltons at room temperature, and work at a pressure of 0.14Mpa , and spray-dry the Acacia oligosaccharide solution passing through the membrane, and the temperature of the spray-drying air outlet is controlled at 75° C. to obtain 8.6 kg of white oligosaccharide powder.

Embodiment 3

[0033] Add 10kg of guar gum powder into the stirring device, add 0.8kg of potassium hydroxide, 1.5kg of methanol, 0.8kg of water, stir for 25 minutes, place the semi-wet wild honey locust gum powder in the microwave drying equipment, adjust the microwave power to 1200 watts, and process After 10 minutes, dissolve the treated rubber powder in water to make a 10% solution, adjust the pH to 7.0 with citric acid, pass the solution through a hollow fiber membrane with a molecular weight cut-off of 2000 Daltons at room temperature, and pass the membrane at a working pressure of 0.15Mpa. Acacia oligosaccharide solution was spray-dried, and the spray drying outlet temperature was controlled at 85° C. to obtain 6.8 kg of white oligosaccharide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com