Preparation method of molecular engram silicon oxide nanometer particle with sensing molecule identification to TNT

A molecular recognition and nanoparticle technology, applied in the field of material science, can solve the problem that molecular recognition has not been reported, and achieve the effect of easy grafting of organic functional groups, large surface area, and wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

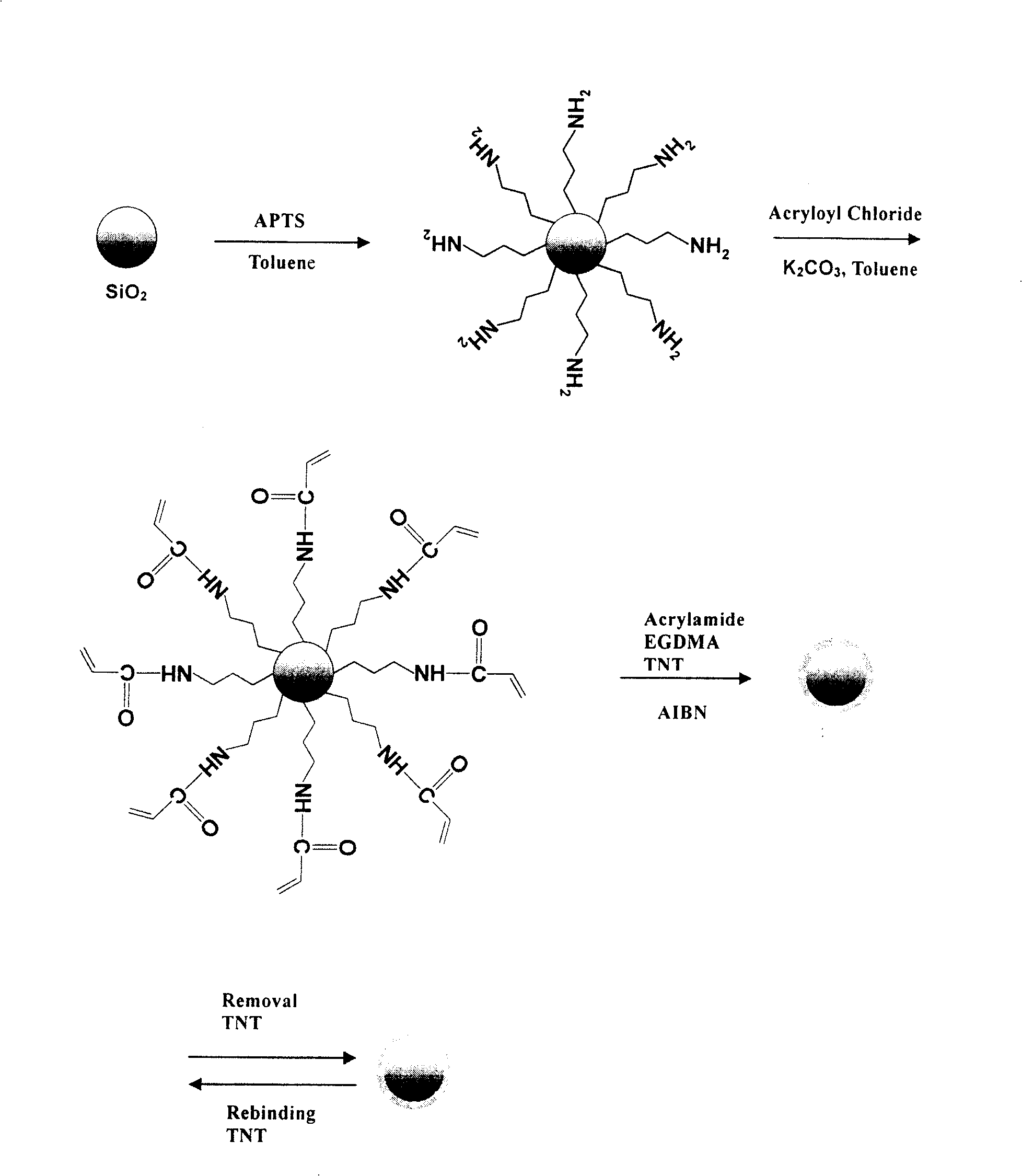

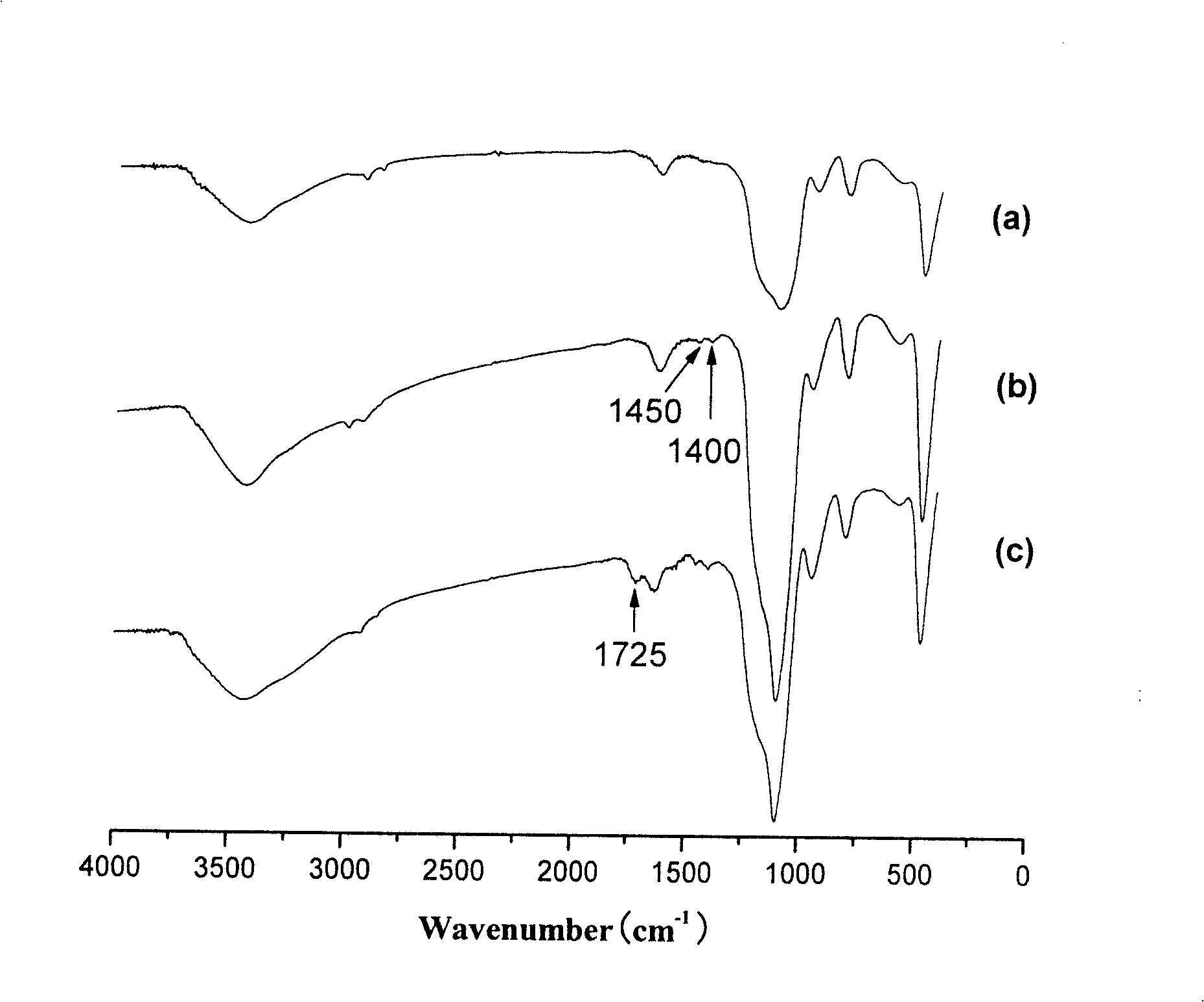

[0039] A chemical preparation method for molecularly imprinted silica nanoparticles with sensitive molecular recognition for TNT, comprising using silica spherical particles as a template and modifying the surface with aminopropyl groups, characterized in that: the silica spherical particles are then Further amidation to make its surface with specific functional groups, the preparation process of the present invention comprises the following two steps:

[0040] The first step is to dissolve the functional monomer, the recognized molecule and the cross-linking agent in 50 ml of acetonitrile so that the concentrations are 0.0020-0.0046 mol / L, 0.00264 mol / L and 0.0080-0.0184 mol / L, and then add mass Initiator with a fraction of 2-5% and 20 mg of a two-step modified spherical template, sealed with nitrogen and deoxygenated, heated to 50°C for 6 hours to form oligomers on the surface of the spherical template, and then heated to 60°C React for 18 hours to form a low-degree polymeri...

Embodiment

[0044] Embodiment: According to the precipitation polymerization reaction, using nano-silicon oxide as a template, a two-step reaction can be used to obtain nanocomposite balls.

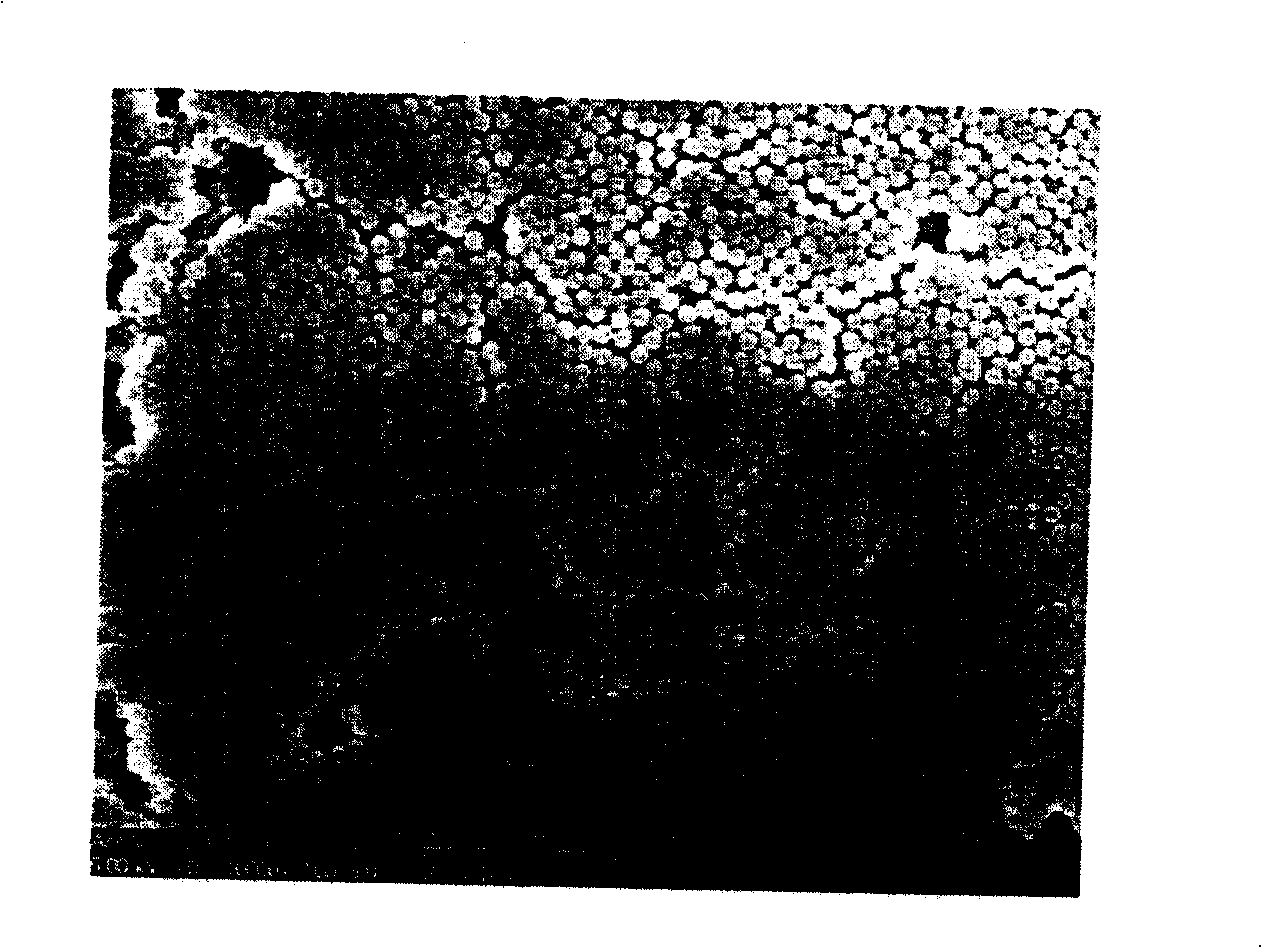

[0045] 1. Synthesis of monodisperse silica sol nanospheres: at room temperature, dissolve 3.6ml tetraethyl orthosilicate (TEOS) in 88.1ml ethanol and stir for three minutes, then add 11.9ml ammonia water (25%) to the above-mentioned The reaction mixture was stirred vigorously for three minutes, then gently for 24 hours. The obtained silica sol nanospheres were dispersed in toluene after three centrifugation washes.

[0046] (1) The silica nanoparticles obtained above were dispersed in 50 ml of toluene, then 1 ml of aminopropyltriethoxysilane (APTS) was added dropwise, and refluxed for 24 hours under an inert atmosphere. The resulting product was dispersed in toluene after three centrifugal washes.

[0047] (2) Add 0.2 g of anhydrous potassium carbonate to the above-mentioned modified silicon oxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com