Nano crystal constructed porous copper oxide aggregate and its preparing method

A technology of copper oxide and nanocrystals, which is applied in the direction of nanostructure manufacturing, copper oxide/copper hydroxide, nanotechnology, etc., can solve the problems of high industrialization cost, product pollution, monodispersion, etc., to improve reaction and catalytic activity, facilitate Effect of recycling and reuse, good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

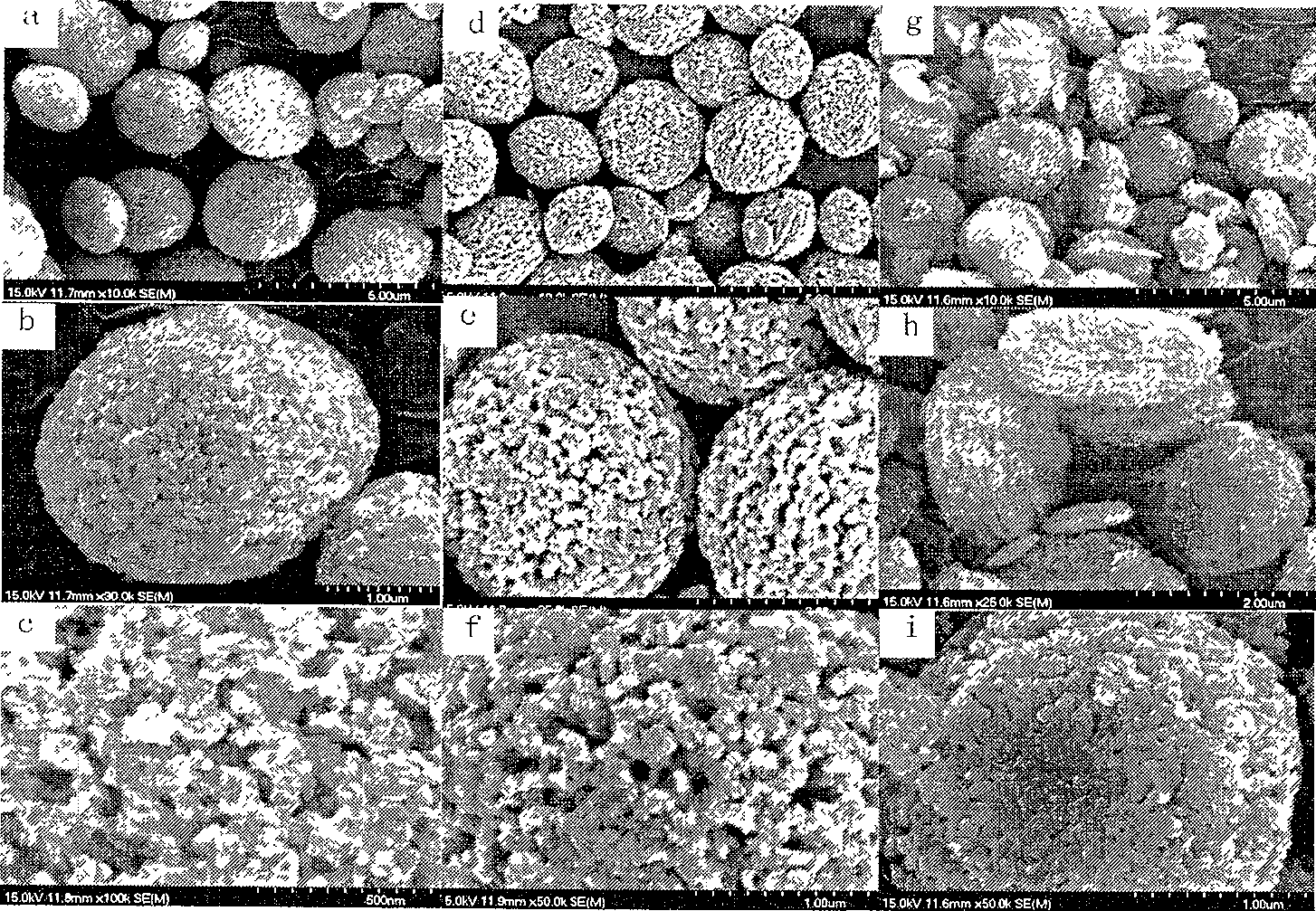

[0025] Dissolve 50g of copper sulfate in 10L of water, and another 29g of potassium oxalate solution in the same volume of water; add the potassium oxalate solution into the stirred copper sulfate solution, the reaction temperature is 5-10°C; react at this temperature for 60min, and age After 2 hours, the material liquid was taken out and dehydrated, and the obtained product was dried in the air at 80°C for 5 hours to obtain oblate spherical copper oxalate powder.

[0026] Place the dried copper oxalate precursor in a muffle furnace, raise the temperature to 400°C at a rate of 5°C / min, keep it warm for 4h, and then slowly cool to room temperature with the furnace temperature to obtain the nanocrystalline porous copper oxide of the present invention Powder.

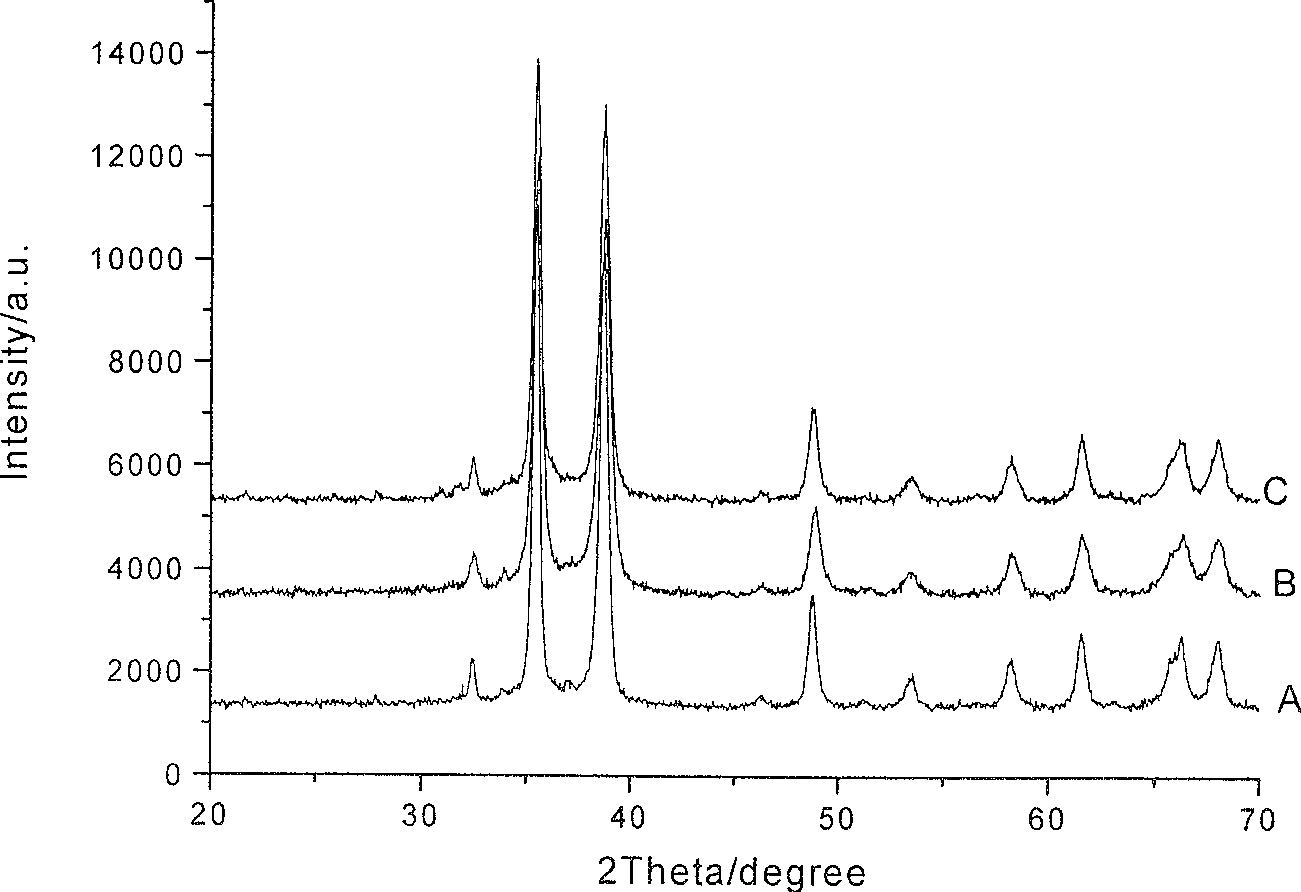

[0027] Thermo NORAN VANTAGE EIS X-ray energy dispersive spectrometer (EDS) was used for energy spectrum analysis, and its composition was determined to be CuO; X-ray diffraction was used to characterize the structure of th...

Embodiment 2

[0030] Soluble oxalate uses ammonium oxalate, press n((NH 4 ) 2 C 2 o 4 ): n(CuSO 4 )) = 1:1 ratio feeding, the amount of ammonium oxalate and copper sulfate is 128g and 200g respectively, the reaction temperature is 20-30°C, and the reaction is 30min; when calcining, the temperature is raised to 300°C at a rate of 2°C / min to calcine the precursor body, and incubated for 8h, and others are implemented in the same manner as in Example 1.

[0031] The analysis result of the obtained porous copper oxide material is similar to that of Example 1.

Embodiment 3

[0033] Soluble oxalate is sodium oxalate, press n(Na 2 C 2 o 4 ): n(CuSO 4) = 1.25:1 ratio feeding, the amount of sodium oxalate and copper sulfate is 335g and 500g respectively, 10L copper sulfate solution is added to the sodium oxalate solution under stirring, the reaction temperature is 50 ~ 60 ℃, reaction 15min; with 10 The temperature was raised to 350°C at a rate of °C / min to calcine the precursor, and kept at this temperature for 6 hours, and the rest were implemented in the same manner as in Example 1.

[0034] The analysis result of the obtained porous copper oxide material is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com