Method for treating chlorine alkali waste water by calcium carbide ethyne method and biological treatment agent thereof

A calcium carbide acetylene and biological treatment technology, applied in sustainable biological treatment, multi-stage water/sewage treatment, biological water/sewage treatment, etc. The effect is unstable and other problems, and the effect of good nitrification effect, good denitrification effect and low cost is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

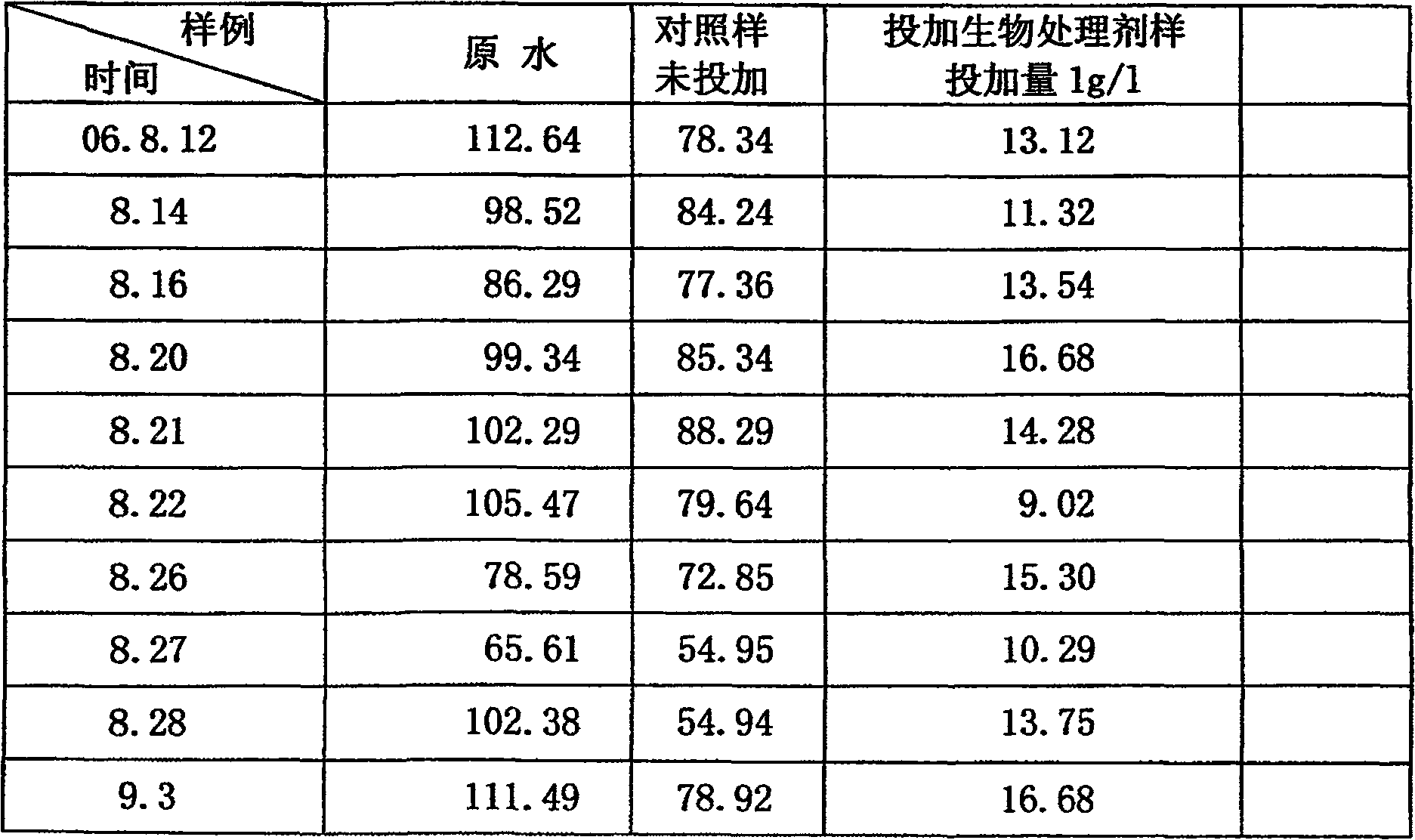

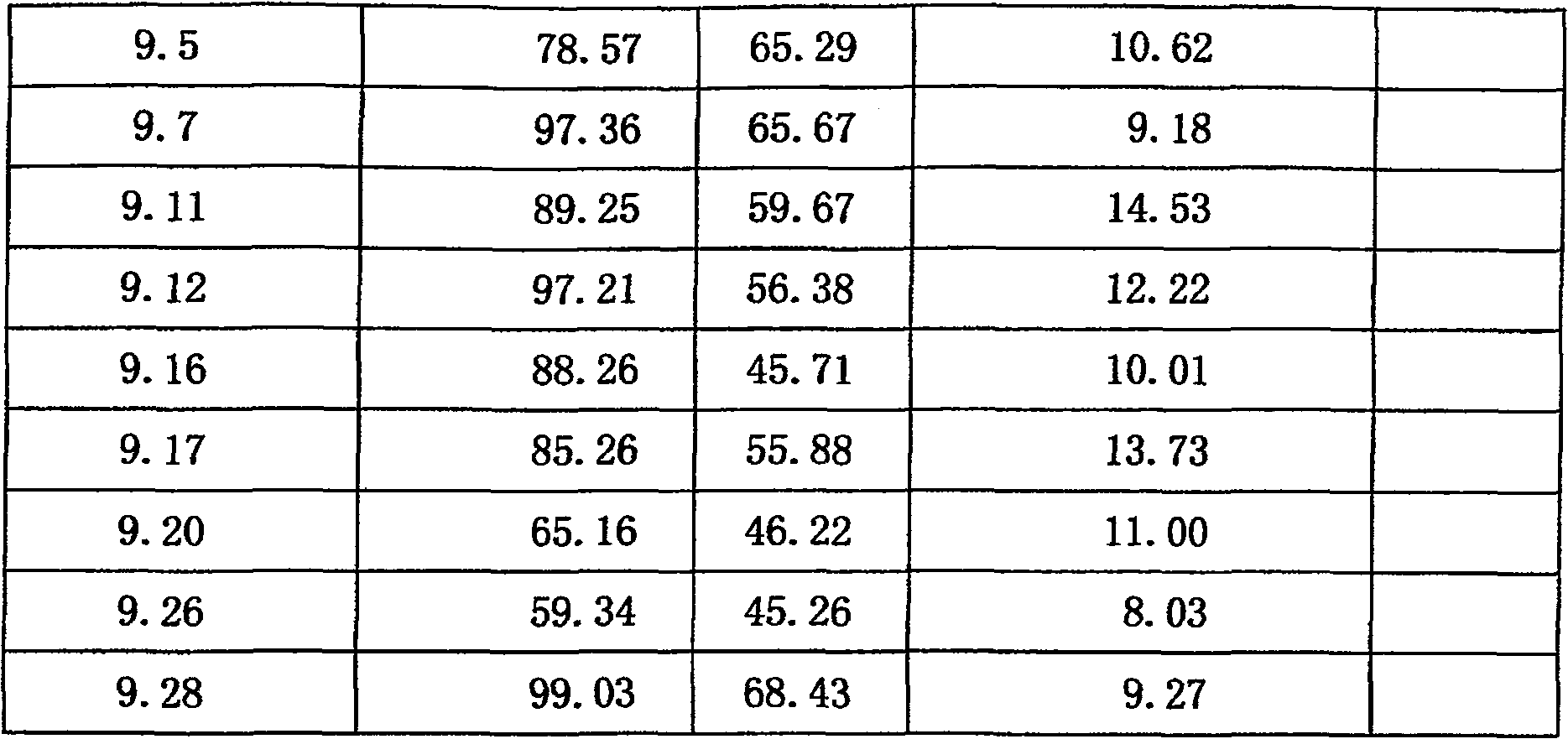

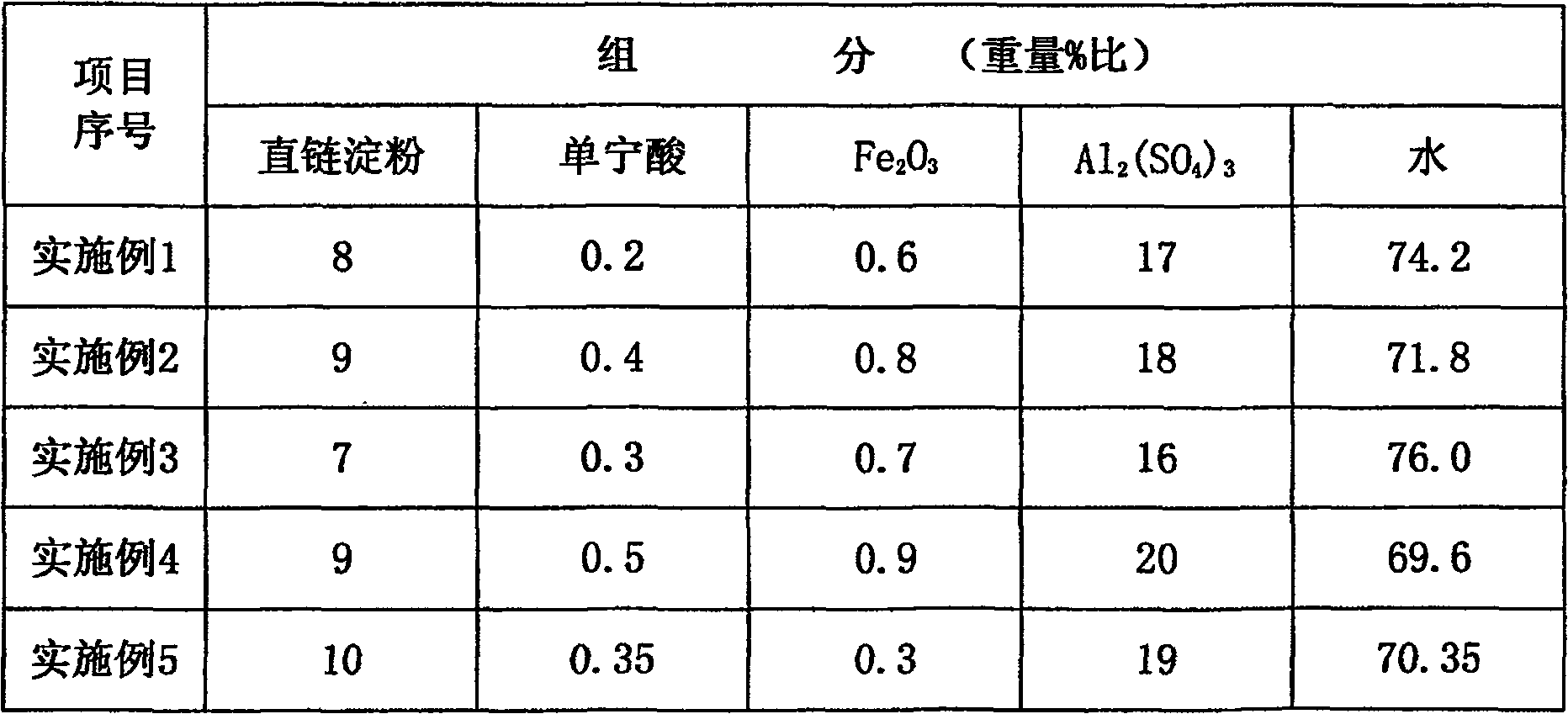

[0037] First prepare the biological treatment agent according to the table below.

[0038]

[0039] The biological treatment agent is an emulsified liquid prepared after modification at a medium temperature (45-60° C.), with a light yellow appearance, a specific gravity of 1.25-1.3, and a solid content of not less than 25%.

[0040] Amylose, Tannic acid, Fe 2 o 3 、Al 2 (SO 4 ) 3 Both serve as the carrier of microorganisms. Compared with the single-component carrier, the function of the coagulation functional group formed is more perfect, which can improve the coagulation performance of activated sludge and the effective sludge concentration per unit volume. In addition, amylose is used as a carbon source for microorganisms; tannic acid is used to precipitate heavy metals and complex cations; Fe 2 o 3 、Al 2 (SO 4 ) 3 Both are used to adsorb polyvinyl alcohol and monomer vinyl chloride.

[0041] The wastewater treatment steps are as follows:

[0042] 1. Chemical pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com