Microwave fast solid phase sintering method for cathode material lithium iron phosphate of lithium ionic cell

A lithium-ion battery and lithium iron phosphate technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of being unsuitable for large-scale industrial production, poor stability of mass production, and reducing sintering time, etc., to achieve excellent pole pieces Processing performance, low cost, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Mix 3080 grams of lithium hydroxide, 5620 grams of ferric oxide, 8261 grams of ammonium hydrogen phosphate and 2240 grams of sucrose, put them into a sand mill, add 8 liters of water, add 20 kilograms of agate balls, and mix for 3.5 hours. Dry the mixed slurry with a spray granulator at a temperature of 200°C, then use a continuous extruder to form a block, and put it into a 2KW microwave reaction furnace. The temperature was raised to 750°C at a rate of 50°C / min, held for 45 minutes, and then cooled to room temperature; after the sintered material was crushed with a crusher, it was graded on a jet mill to obtain lithium iron phosphate with uniform particles.

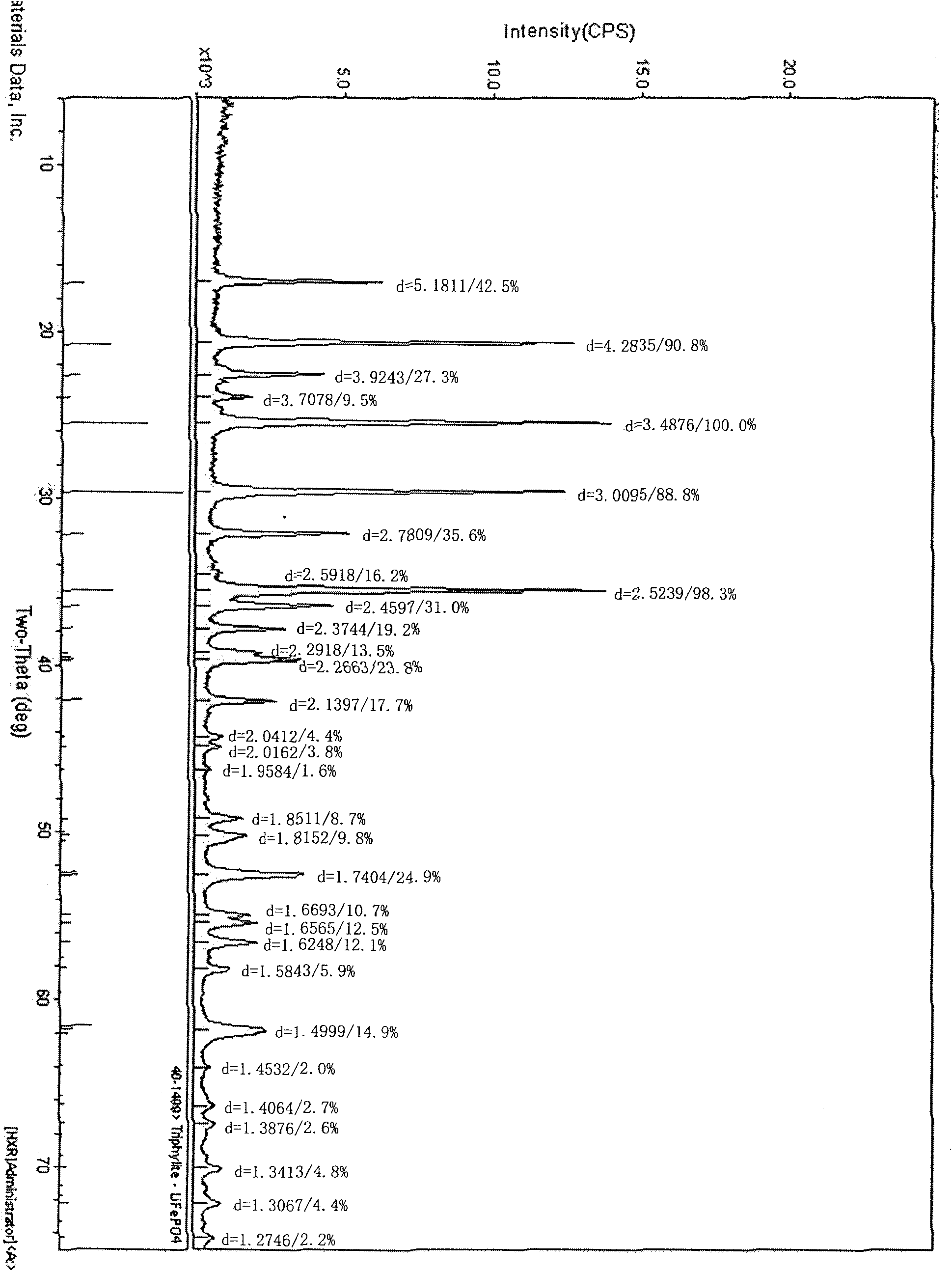

[0029] The measured carbon content in the material is 5.6%, and its XRD spectrum is shown in figure 1 , compared with the standard card, it is olivine lithium iron phosphate with intact crystal form, no diffraction peak of carbon is observed, indicating that carbon exists as amorphous carbon.

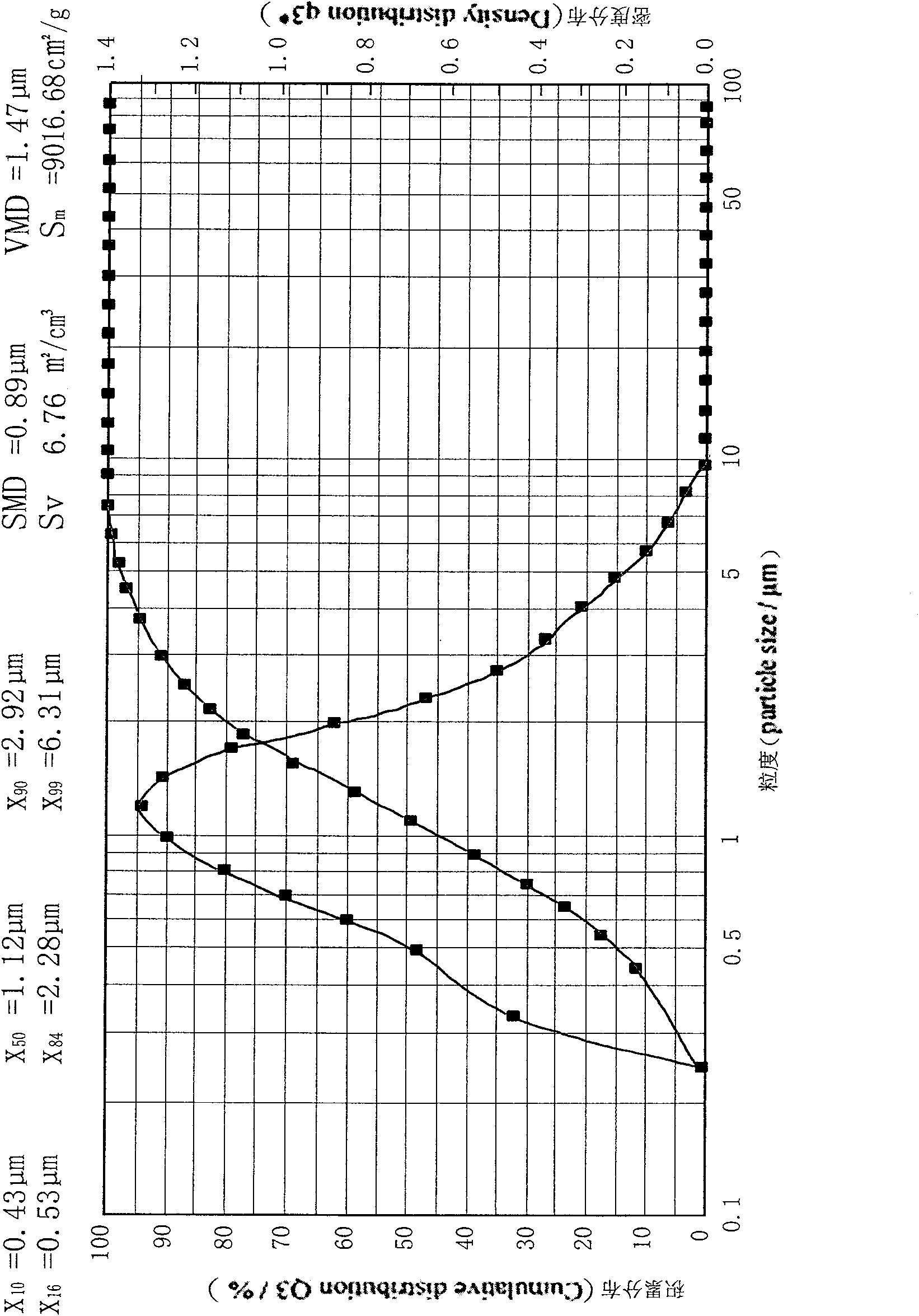

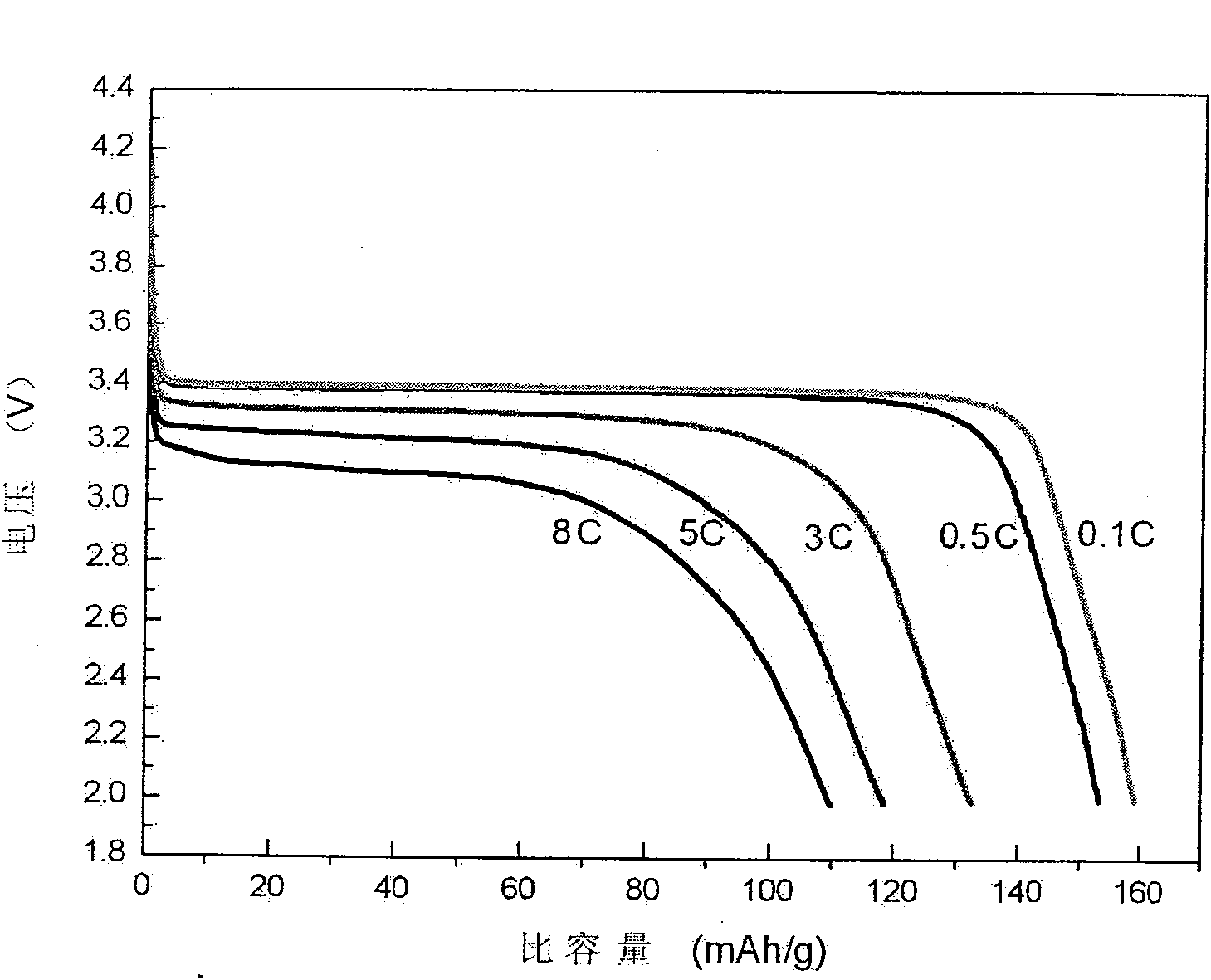

[0030] The measur...

Embodiment 2

[0034] Mix 3695 grams of lithium carbonate, 7985 grams of ferric oxide, 123206 grams of ammonium hydrogen phosphate and 1600 grams of sucrose, put them into a sand mill, add 8 liters of water, add 20 kilograms of agate balls, and mix for 2 hours. The mixed slurry is finely ground with an ultra-fine mill, then dried in an oven at a temperature of 100°C, then made into a block using an extruder, and put into a microwave reaction furnace with a power of 3KW. Under a nitrogen atmosphere of 1 / min, the temperature was raised to 800°C at a rate of 60°C / min, kept for 30 minutes, and then cooled to room temperature. After the sintered material is crushed with a crusher, it is classified on a jet mill to obtain lithium iron phosphate with uniform particles.

[0035] The carbon content of the active material was measured to be 5.8%, and the simulated button battery was prepared according to the method of Example 1. After the battery was assembled, the reversible gram capacity was 148mAh / ...

Embodiment 3

[0037] Mix 30.0 kg of lithium phosphate, 62.2 kg of ferric oxide, 68.7 kg of diammonium hydrogen phosphate, 24.0 kg of sucrose and 12.0 kg of glucose, put them into a mixer, add 50 liters of alcohol, add 200 kg of agate balls, and mix for 2 hours . Then mix with an ultrafine mill for 1 hour, dry the mixed slurry with a spray granulator at a temperature of 180°C, then put the powder into a crucible, and put it into a continuous In a microwave reaction furnace for industrial use, under a nitrogen atmosphere of 10 liters / min, the temperature was raised to 700°C at a rate of 40°C / min, kept for 60 minutes, and then cooled to room temperature. After the sintered material is crushed with a crusher, it is classified on a jet mill to obtain lithium iron phosphate with uniform particles.

[0038] The obtained materials were sent to the lithium-ion battery factory to prepare electrode sheets and assembled into 17500 cylindrical batteries. Under the charge and discharge rate of 0.5C, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com