Coal liquifying process based on pentacarbonyl iron as catalyst

A technology of iron pentacarbonyl and catalyst, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. , equipment, technical requirements and other issues, to achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

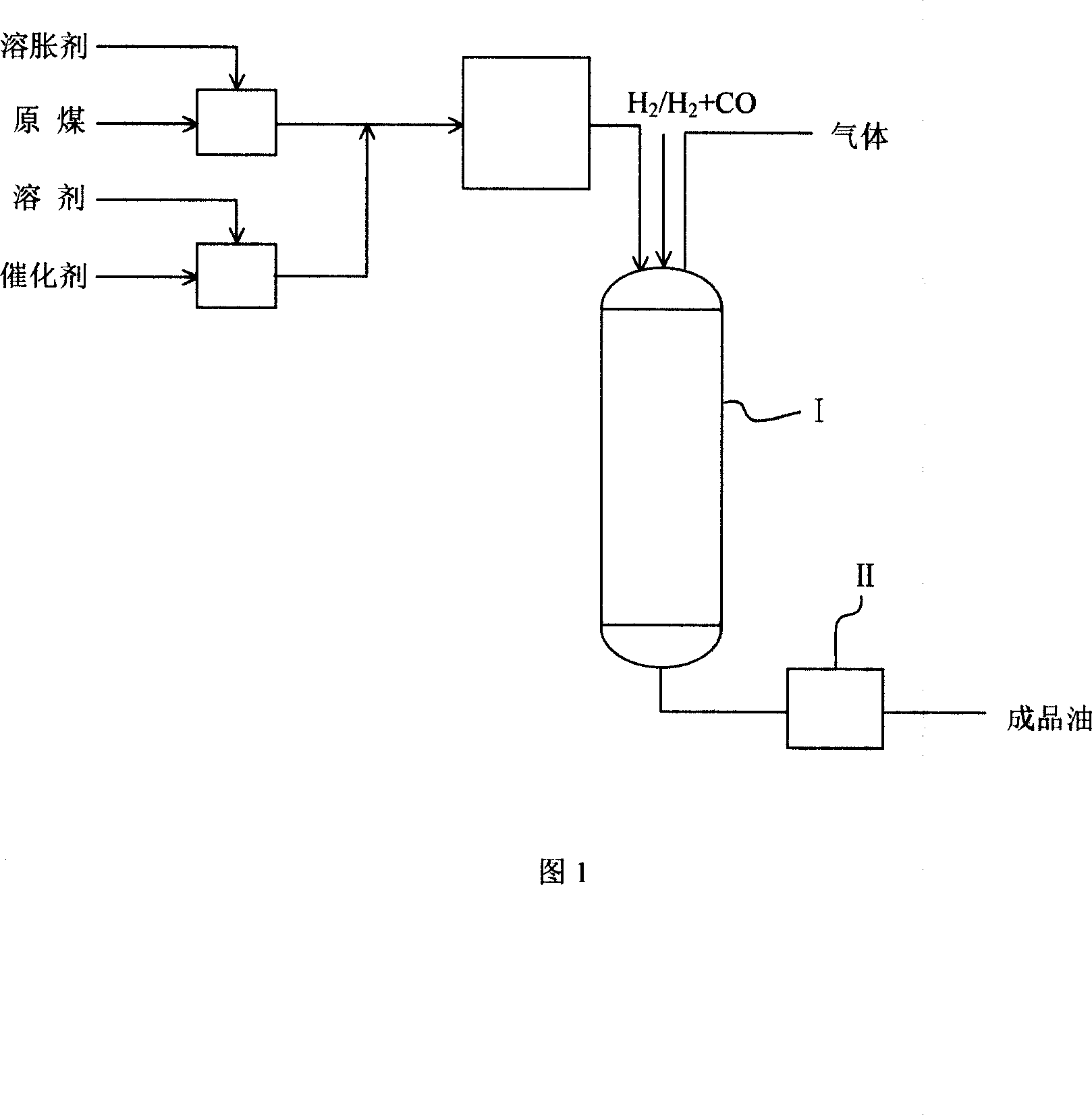

[0025] ③Preparation of coal slurry, mixing pulverized coal with a catalyst-containing hydrogen-donating solvent, and stirring to obtain a coal slurry;

[0026] ④Coal slurry liquefaction reaction, import the coal slurry into the high-pressure stirring reactor of the liquefaction reaction equipment, seal the equipment, replace or evacuate the air in the reactor, and then inject hydrogen or a mixed gas of hydrogen and carbon monoxide to reach the reaction pressure, and slowly heat the equipment to Liquefaction reaction temperature, heat preservation, under the condition of continuous or intermittent stirring, the coal slurry can fully complete the liquefaction cracking hydrogenation reaction;

[0027] ⑤ Separation of the product after the liquefaction reaction, the gaseous product of the liquefaction reaction is exported and separated, and the available hydrogen or carbon monoxide is recycled; the liquid product is introduced into the distillation equipment, and the boiling point ...

Embodiment 1

[0036] After pulverizing the dried coal with a ball mill, sieve through 100 meshes, mix the coal powder and swelling agent methanol, fully stir, the swelling time is 24 hours, recover the swelling agent through low-temperature distillation, and dry the swollen coal powder under the protection of nitrogen Dry;

[0037] Add catalyst iron pentacarbonyl liquid into the hydrogen-donating solvent tetrahydronaphthalene, the amount added is 0.5% of the coal mass in terms of iron atoms, and stir under the condition of avoiding light to make it fully mixed;

[0038] Mix the above-mentioned swollen coal powder and the catalyst-containing hydrogen-donating solvent in a ratio of 1:1, stir well to form a coal slurry, and then introduce the coal slurry into a high-pressure stirred reactor, replace the air and seal it, add hydrogen and pressurize it by 2MPa Up to 8MPa, set the reaction temperature to 350°C, slowly heat the equipment to the set temperature and keep it warm for 60 minutes to ca...

Embodiment 2

[0042] 80 mesh coal powder was swollen with acetone for 4 hours, the coal powder and the cresol hydrogen-donating solvent containing the catalyst were mixed according to the ratio of 2.5:1, and the addition amount of the catalyst iron pentacarbonyl liquid was 0.1% of the coal mass in terms of iron atoms. Liquefaction was carried out in the same manner as in Example 1. The temperature of the liquefaction reaction was 380° C., the pressure of the liquefaction reaction was 14 MPa, and the reaction time of the liquefaction reaction was 10 minutes. The reaction product adopts the same analysis method to calculate the liquefaction conversion rate, and weighs the mass of various distillation products, and calculates its percentage in the liquefaction reaction product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com