Combustion system for changing methanol into hydrogen fuel used in industrial furnace and thermal power plant.

A technology for combustion systems and thermal power plants, applied in burners, combustion methods, liquid fuel supply/distribution, etc., can solve the adverse effects of equipment safety, controllability, system operation stability, large size of waste heat heaters, and coal burning. pollution hazards and other problems, to alleviate excessive dependence on oil, save energy, and improve conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

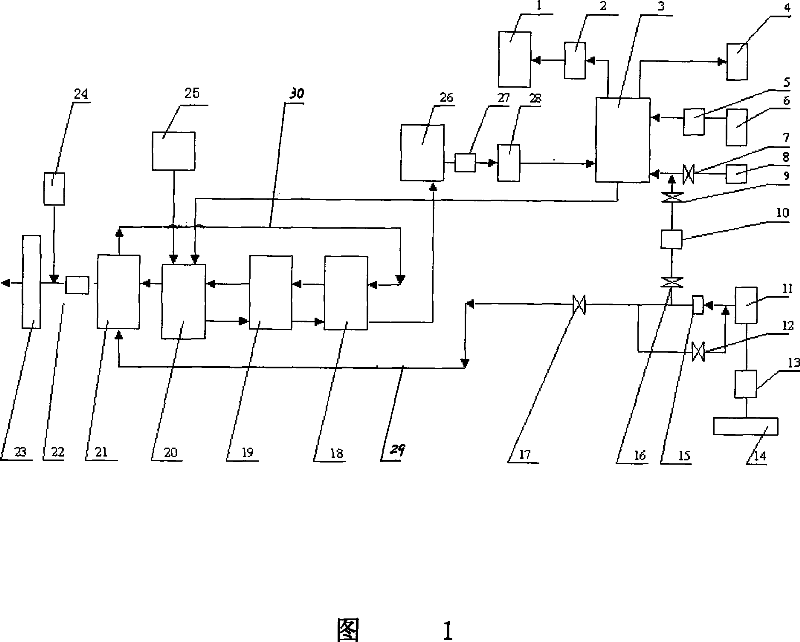

[0037] Combustion system for converting methanol into hydrogen fuel for industrial kilns and thermal power stations, including hydrogen production combustion system, heat transfer oil heating circulation system, furnace waste heat flue gas heating system, air preheating system, start-up system and bypass recirculation system, which states:

[0038] The hydrogen production combustion system consists of a methanol station 14 connected in series through pipelines, a methanol feed pump 13, a methanol fuel tank 11, a methanol metering pump 15, a starting system switching valve 17, a methanol preheating and hydrogen storage tank 21, a vaporizer 18, and a heating Device 19, catalyst activation system 25, methanol catalytic pyrolysis hydrogen conversion generator 20, steam-water separator 22, flame arrester 24 and burner 23;

[0039]The heat transfer oil heating cycle system consists of a heat transfer oil tank 26, a filter 27, a heat transfer oil circulation pump 28, a waste heat hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com