Raw material formulation and method for low-temperature silicon carbide synthesization

A technology of silicon carbide and low temperature, which is applied in the field of raw material formula for low temperature synthesis of silicon carbide, can solve the problems of low carbothermal reduction temperature and long reaction time, and achieve the effect of simple equipment, easy source and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

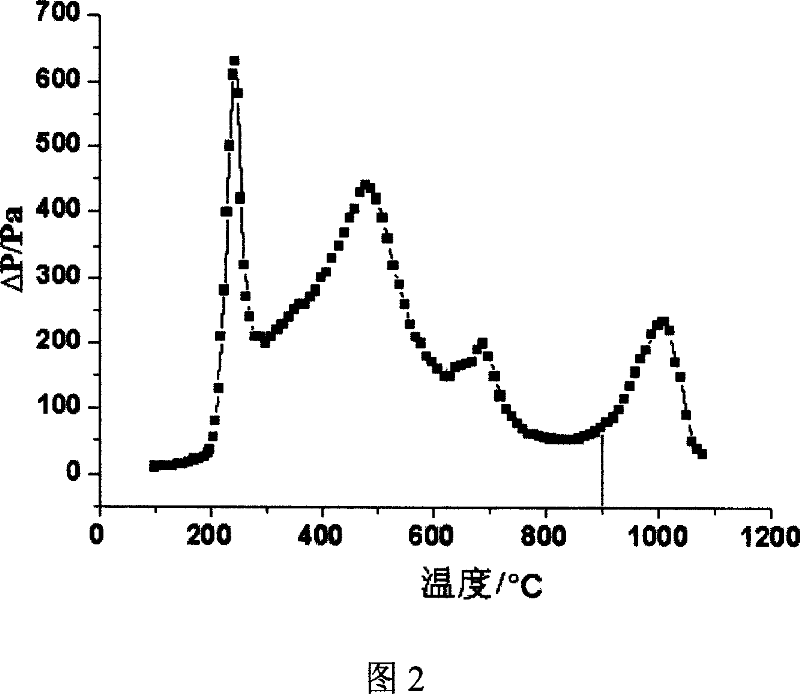

[0021] The corresponding minimum reaction temperature in Example 2 was 900°C.

example 3

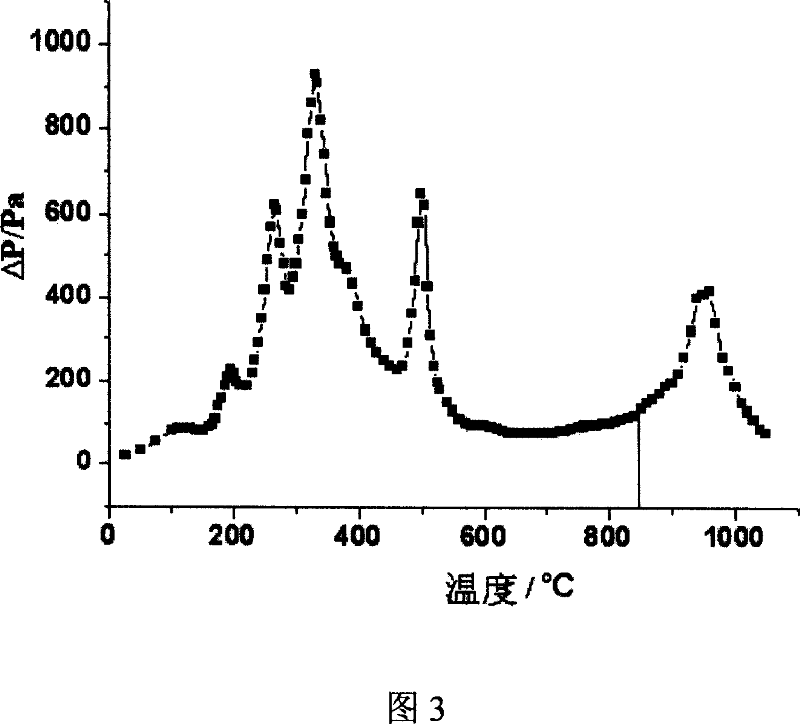

[0022] The corresponding minimum reaction temperature in Example 3 was 850°C.

Embodiment 1

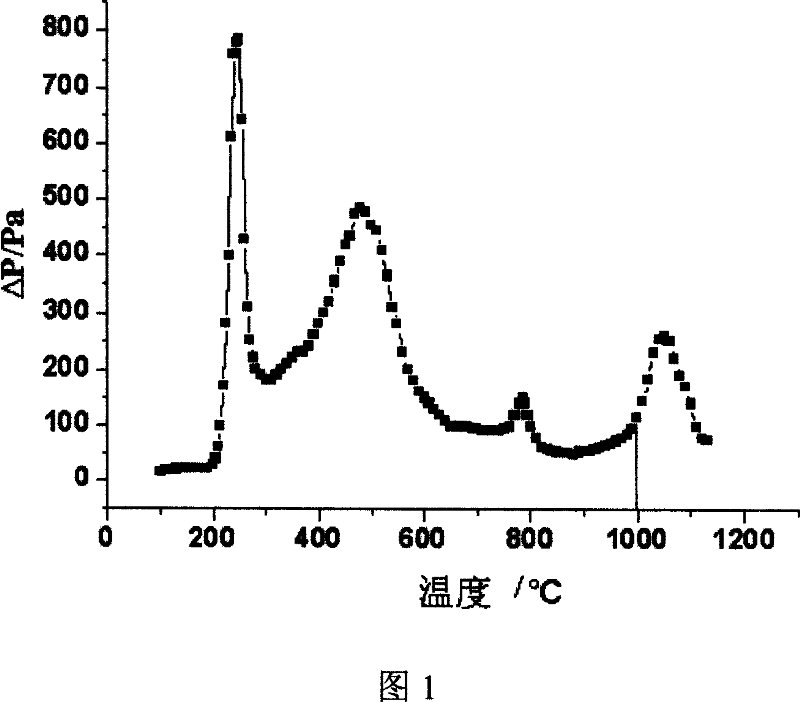

[0024] 25g of sucrose was dissolved in a mixed solution of 20ml of deionized water and 30ml of absolute ethanol, 3.5g of ferric nitrate (ferric nitrate nonahydrate) was added, and 50ml of TEOS and 10ml of 3.5% oxalic acid solution were added dropwise at the same time. Stir well at 60°C for hydrolysis until the solution becomes gel. The gel was dried at 100 °C for 30 h to obtain a silicon carbide precursor xerogel. The resulting dry glue was placed in a vacuum graphite furnace, and the air pressure in the furnace was pumped to 10 -2 Pa, continue to start the mechanical pump, heat at a heating rate of 20°C / min under power vacuum conditions, record the change of air pressure in the furnace with temperature, and draw a curve of air pressure in the furnace versus temperature, as shown in Figure 1, determine the carbon The minimum temperature required to prepare silicon carbide by thermal reduction is 1000°C. Then the reaction is carried out under the condition of 1000℃ power vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com