Nanocrystalline WC-Co-Ni catalyst

A catalyst and nanocrystalline technology, applied in the field of nanocrystalline WC-Co-Ni catalysts, can solve problems that have not yet been seen in literature and application reports, and achieve the effects of wide application prospects, high catalytic performance, and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

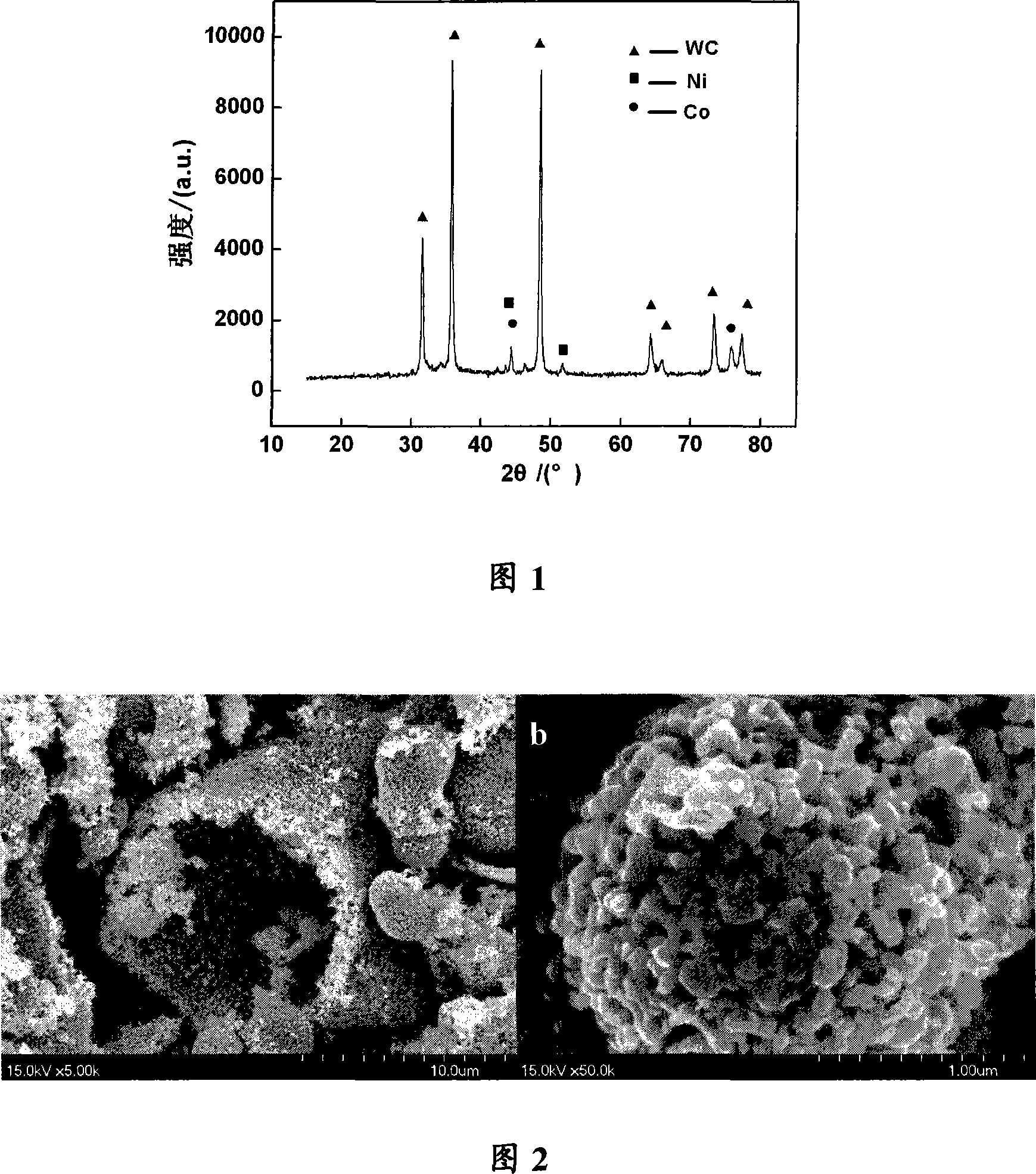

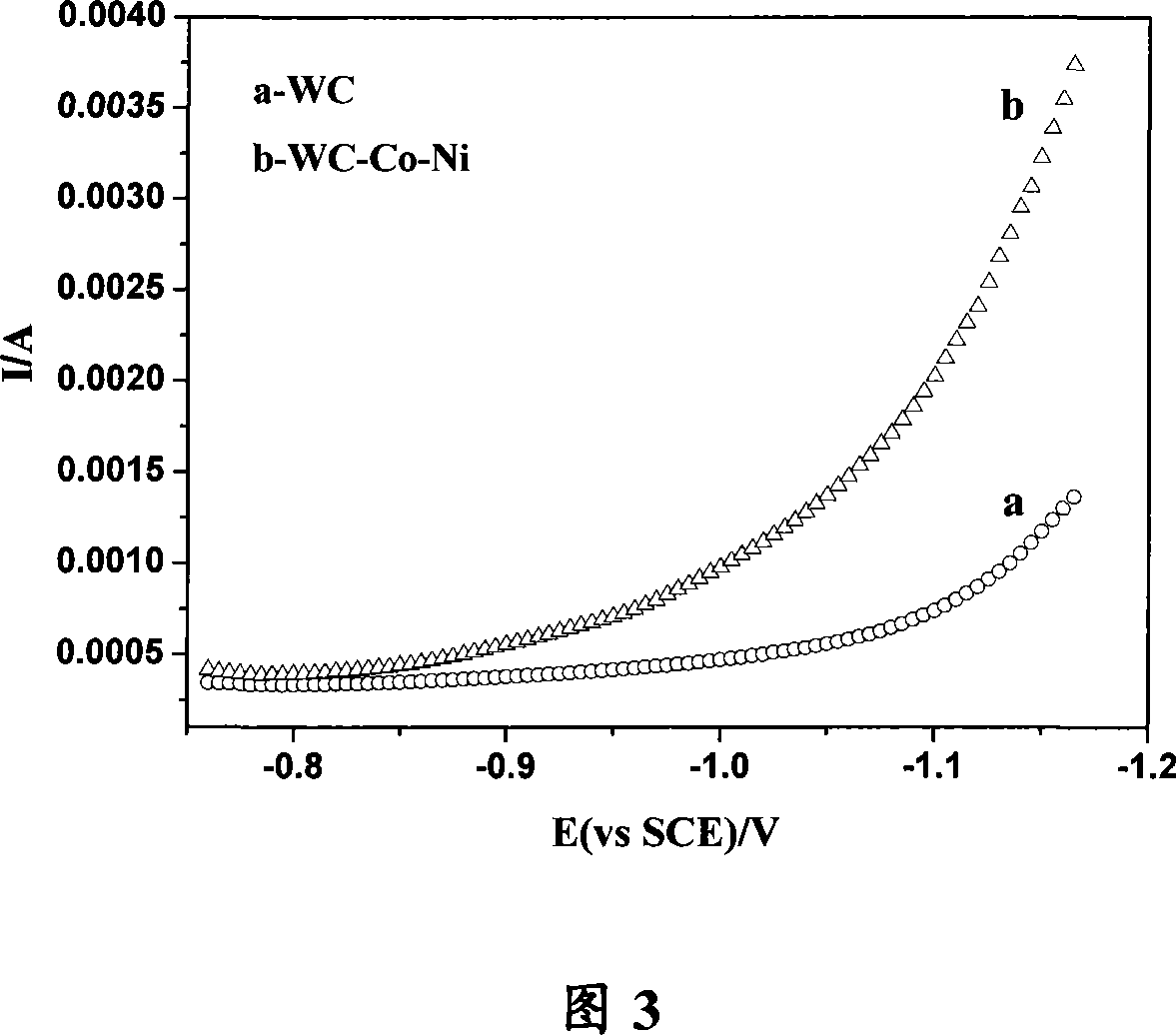

Embodiment 1

[0035] 16.25g of ammonium metatungstate, 1.63g of cobalt nitrate and 1.63g of nickel nitrate were fully mixed in distilled water to prepare a mixed aqueous solution with a mass concentration of 10%. Ultrasonic vibration was used for 30 minutes at room temperature, and then stirred by a magnetic stirrer. The solution is introduced into a spray dryer for spray drying to obtain oxide particle precursors. In the spray drying process, the inlet flow rate of the mixture aqueous solution is 20mL / min, the air inlet flow rate is 600L / h, and the inlet nozzle temperature of the hot air nozzle is 200 °C, the temperature at the outlet of the tail gas is 100 °C; put the dried precursor into a quartz boat and place it in a tube-type resistance furnace, pass hydrogen gas at 450 °C, perform 2 hours of baking heat treatment, and then raise the temperature to 750 °C , into the mixed gas of methane and hydrogen for reductive carbonization, the mass ratio of methane and hydrogen mixed is 1:8, the g...

Embodiment 2

[0037]Fully mix 20.20g ammonium paratungstate, 0.20g cobalt oxalate and 0.20g nickel chloride in distilled water to prepare a mixed aqueous solution with a mass concentration of 5%, vibrate ultrasonically for 10 minutes at room temperature, and then stir the solution with a magnetic stirrer Import into a spray dryer for spray drying to obtain oxide particle precursors. During the spray drying process, the inlet flow rate of the mixture aqueous solution is 5mL / min, the air inlet flow rate is 400L / h, and the inlet nozzle temperature of the hot air nozzle is 160°C. The temperature at the outlet of the tail gas was 80°C; the dried precursor was loaded into a quartz boat and placed in a tubular resistance furnace, and hydrogen gas was introduced at 400°C for 0.5 hours of calcination heat treatment, then the temperature was raised to 900°C, and the The mixed gas of methane and hydrogen was added for reductive carbonization, the mass ratio of methane and hydrogen mixed was 1:15, the g...

Embodiment 3

[0039] 22.10g tungsten hexacarboxylate, 0.22g cobalt acetate and 4.42g nickel acetate were fully mixed in distilled water to prepare a mixed aqueous solution with a mass concentration of 30%. Ultrasonic vibration was used at room temperature for 60 minutes, and then the mixture was stirred with a magnetic stirrer. The solution is introduced into a spray dryer for spray drying to obtain oxide particle precursors. During the spray drying process, the inlet flow rate of the mixture aqueous solution is 40mL / min, the air inlet flow rate is 800L / h, and the inlet nozzle temperature of the hot air nozzle is 250°C , the temperature at the outlet of the tail gas is 120°C; the dried precursor is loaded into a quartz boat and placed in a tubular resistance furnace, and hydrogen gas is introduced at 500°C for 1 hour of baking heat treatment, and then the temperature is raised to 600°C. The mixed gas of methane and hydrogen is introduced for reduction carbonization, the mass ratio of methane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com