Thin-film material for medical purpose

A film material and plastic technology, applied in the field of making blood and blood components, can solve the problems of poor air permeability, low plasticization efficiency, brittleness, etc., and achieve the effects of reducing cost, improving quality and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

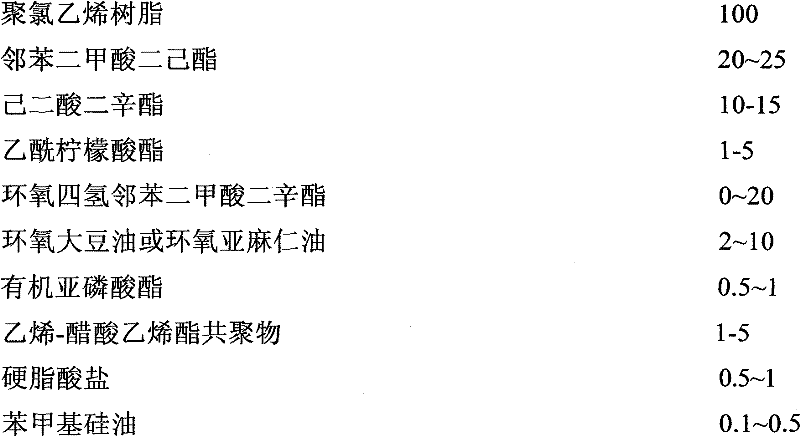

[0042] A kind of medical film material, its used plastic main body is polyvinyl chloride (PVC) resin, concrete component and content are (weight part):

[0043] Polyvinyl chloride resin (PVC) 100

[0044]Dihexyl phthalate (DEHP) 20

[0045] Dioctyl adipate (DOA) 10

[0046] Acetyl Citrate 1

[0047] Dioctyl Epoxy Tetrahydrophthalate (EPS) 20

[0048] Epoxidized soybean oil (ESO) 3

[0049] Organic phosphite (602) 0.5

[0050] Ethylene-vinyl acetate copolymer (EVA) 4

[0052] Benzyl silicone oil 0.2

[0053] Mix the above-mentioned ingredients in proportion, and use the mature PVC plastic processing technology to perform the following steps:

[0054] (1) Kneading The materials of the above proportioning ratio are fully stirred after being pressurized and heated in a stainless steel container, and then discharged;

[0055] (2) Granulation After kneading, extrude and granulate under the set mature process parameters;

[0056] (3) Calenderin...

Embodiment 2

[0059] A kind of medical film material, its used plastic main body is polyvinyl chloride (PVC) resin, concrete component and content are (weight part):

[0060] Polyvinyl chloride resin (PVC) 100

[0061] Dihexyl phthalate (DEHP) 25

[0062] Dioctyl adipate (DOA) 14

[0063] Acetyl Citrate 3

[0064] Dioctyl Epoxy Tetrahydrophthalate (EPS) 2

[0065] Epoxy Linseed Oil (ELO) 8

[0066] Organic phosphite (CH55) 1

[0067] Ethylene-vinyl acetate copolymer (EVA) (or polyurethane) 1

[0068] Calcium Zinc Composite Stabilizer 1

[0069] Benzyl silicone oil 0.5

[0070] In this formula, CH55 is used instead of 602 in the stabilizer system, and the calcium-zinc composite stabilizer is used instead of stearate (calcium stearate, zinc and aluminum). The formula has better safety and higher thermal stability.

[0071] The above-mentioned components of the present invention are mixed, granulated and calendered to form a film material with a thickness of 0.35-0.45 mm. The obtained...

Embodiment 3

[0073] A kind of medical film material, its used plastic main body is polyvinyl chloride (PVC) resin, concrete component and content are (weight part):

[0074] Polyvinyl chloride resin (PVC) 100

[0075] Dihexyl phthalate (DEHP) 22

[0076] Dioctyl adipate (DOA) 18

[0077] Acetyl citrate 5

[0078] Dioctyl Epoxy Tetrahydrophthalate (EPS) 7

[0079] Epoxy Linseed Oil (ELO) 10

[0080] Organic phosphite (CH55) 0.6

[0081] Ethylene-vinyl acetate copolymer (EVA) 5

[0082] Stearate 0.7

[0083] Benzyl silicone oil 0.1

[0084] The raw materials used in this formula are produced according to the normal production steps after being measured, and made into pellets, which are mixed, granulated and calendered to form a film material with a thickness of 0.35-0.45mm. The obtained film material is soft and transparent, has good air permeability, good thermal stability and good low temperature resistance. The film is heat-synthesized into bags of different specifications on a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com