Water soluble magnetic nanometer crystal with high dissolvability and method of producing the same

A magnetic nano, high solubility technology, applied in the direction of magnetic objects, magnetic materials, microsphere preparation, etc., can solve the problems that have not been reported in literature and domestic and foreign patents, and achieve the effect of simple technical route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

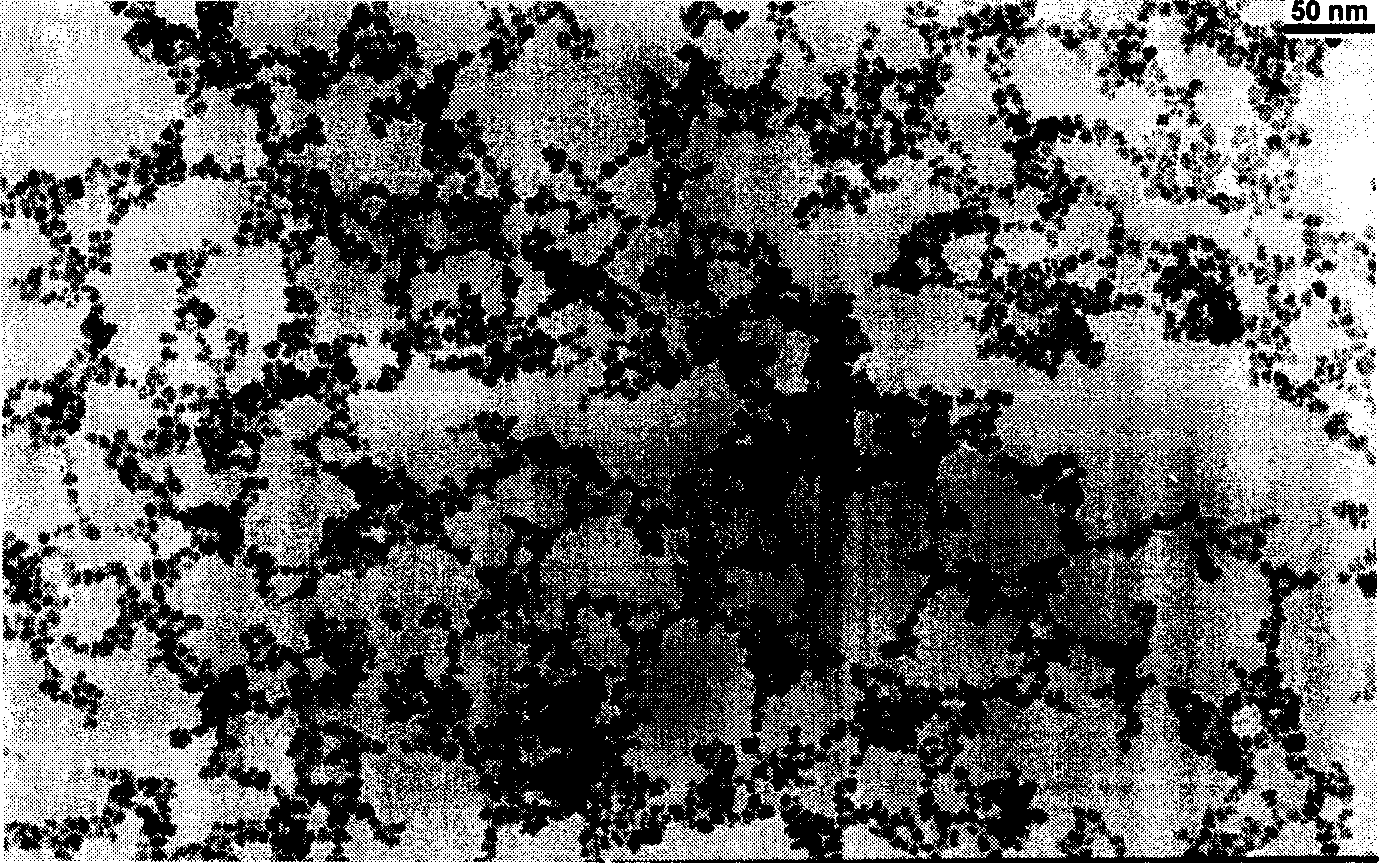

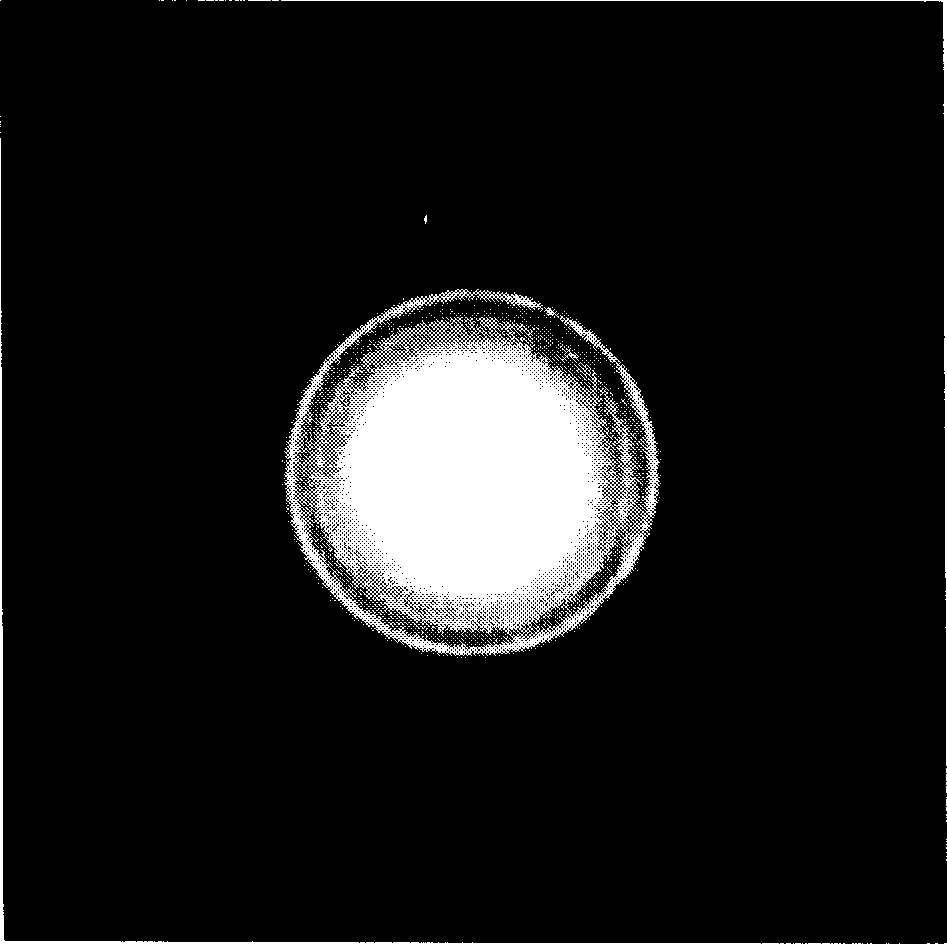

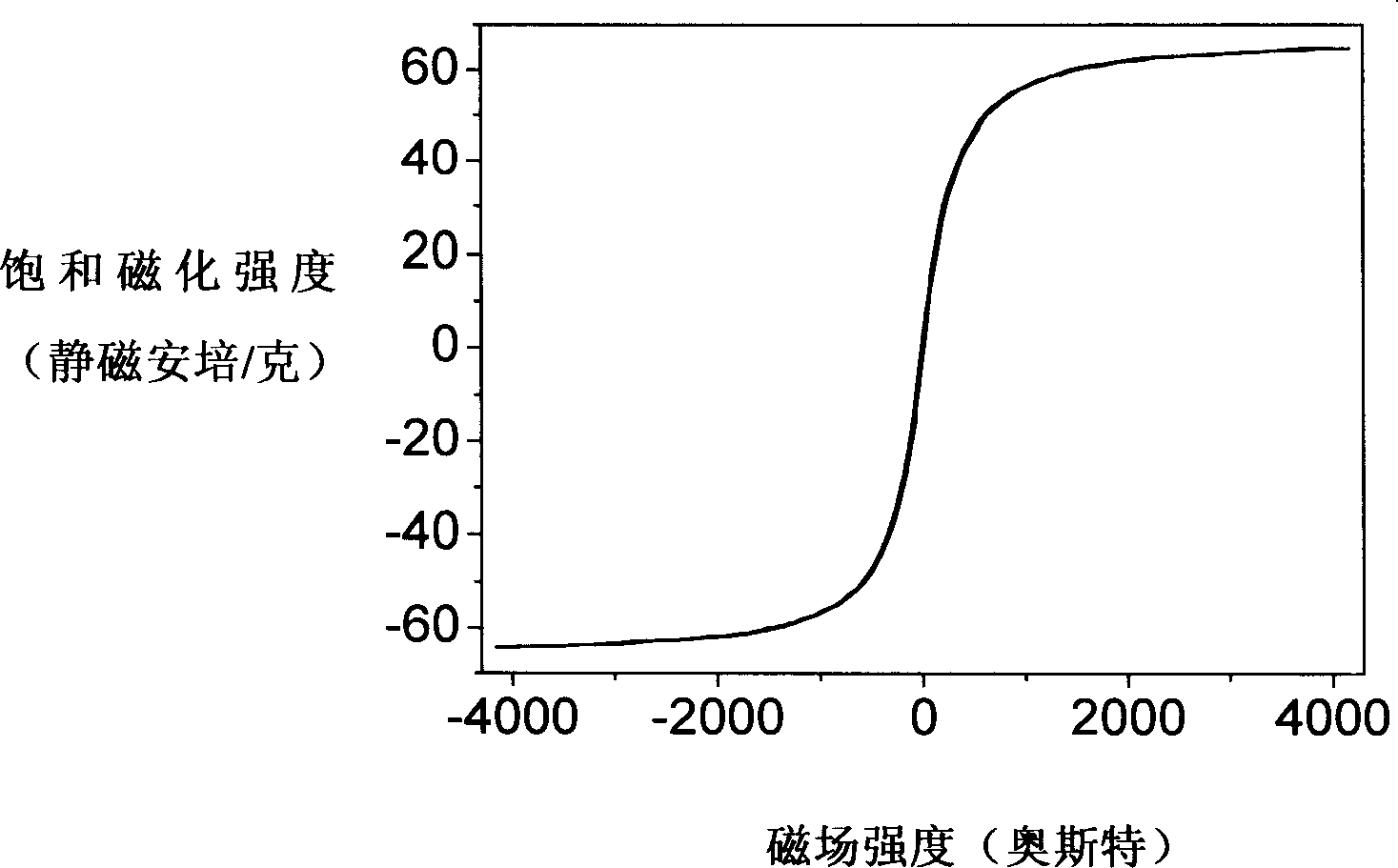

Embodiment 1

[0053] Dissolve 7.2345g of iron acetylacetonate in 500mL of N-vinylpyrrolidone to form a solution, put the above solution into a 1000mL three-neck flask, then pass in nitrogen gas to remove oxygen for 30-90 minutes, and heat at 190-210°C for 0.5-3 The reaction is carried out within hours, and at the same time as the formation of the magnetic nanocrystals, water-soluble and biocompatible poly-N-vinylpyrrolidone macromolecules are formed in situ on the surface of the nanocrystals. Then the reaction solution is cooled to room temperature, the reaction solution is precipitated with a mixed solvent of ethanol and ether, and magnetic particles with strong magnetic response are obtained by magnetic separation or centrifugation. Then, the ferroferrogen tetroxide magnetic nanocrystals with high crystallinity, narrow dispersion and strong magnetic response are obtained through multiple washings with a mixed solvent of ethanol and ether, magnetic separation and centrifugal separation. Th...

Embodiment 2

[0055] Weigh 4.9258g five-carbon base iron (Fe(CO) 5 ) was dissolved in 500mL N-vinylpyrrolidone to form a solution, the above solution was put into a 1000mL three-neck flask, and then nitrogen gas was introduced to remove oxygen for 30-90 minutes, and heated at 190-210°C for 0.5-2 hours. Simultaneously with the formation of crystals, water-soluble and biocompatible poly-N-vinylpyrrolidone macromolecules are formed in situ on the surface of the nanocrystals. Then the reaction solution was cooled to room temperature, and the reaction solution was precipitated with methanol solvent, and subjected to centrifugation or magnetic separation to obtain a black precipitate. Re-dissolving the precipitate with methanol solvent, centrifuging the precipitate, and drying to obtain ferroferric oxide magnetic nanocrystals with high crystallinity, narrow dispersion, and strong magnetic response. The magnetic nano crystal can be well dissolved in neutral water (pH=6-8), so as to obtain a neutr...

Embodiment 3

[0057] Weigh 4.8862g of anhydrous ferric chloride and dissolve it in 500mL of N-vinylpyrrolidone to form a solution, put the above solution into a 1000mL three-necked flask, then pass through nitrogen to remove oxygen for 30-90 minutes, and heat at 190-210°C In 1-4 hours, water-soluble and biocompatible poly(N-vinylpyrrolidone) macromolecules are formed on the surface of the nanocrystals at the same time as the magnetic nanocrystals are formed. Then the reaction solution was cooled to room temperature, and the treatment method was as in Example 1. The black precipitate obtained after drying is dissolved in neutral water (pH=6-8) to obtain a neutral magnetic fluid with strong magnetic response and superparamagnetism. The particle shape is a spherical magnetic nano crystal, and the particle diameter is between 10 and 14 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com