Stacking organic photovoltaic power cell taking three layers organic hetero-junction thin film as middle electric pole

A technology of organic photovoltaic cells and intermediate electrodes, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as poor light transmission properties, quenching, loss of open circuit voltage and fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

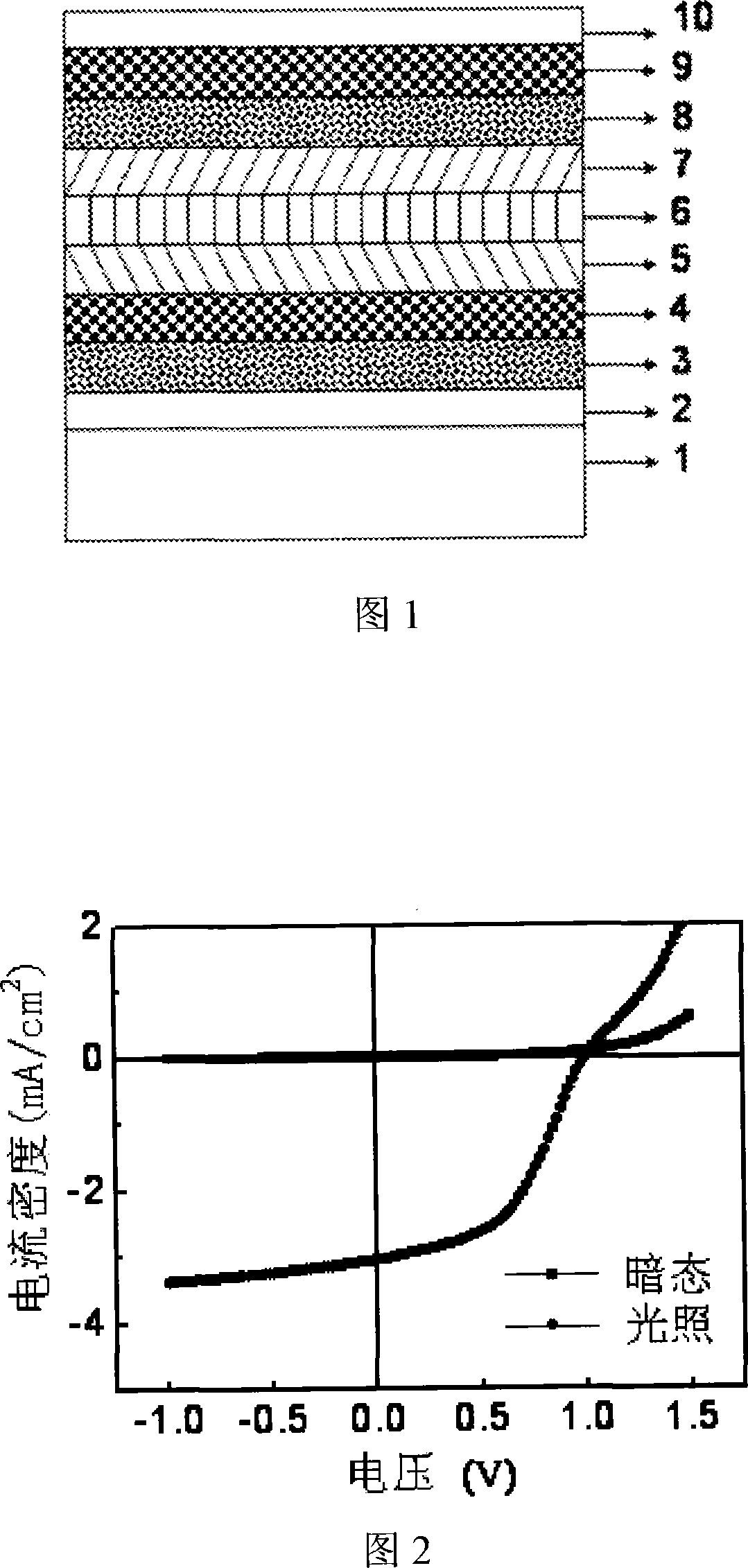

Embodiment 1

[0045] Nickel phthalocyanine (NiPc), tin phthalocyanine (SnPc), copper phthalocyanine (CuPc), cobalt phthalocyanine (CoPc), zinc phthalocyanine (ZnPc), lead phthalocyanine (PbPc), vanadium phthalocyanine (VOPc) , Titanium phthalocyanine (TiOPc), iron phthalocyanine chloride (FeClPc), titanium phthalocyanine dichloride (TiCl 2 Pc), tin phthalocyanine dichloride (SnCl 2 Pc), phthalocyanine indium chloride (InClPc), hexadecachloro phthalocyanine aluminum chloride (Cl 16 AlClPc), phthalocyanine manganese chloride (MnClPc), phthalocyanine gallium chloride (GaClPc), phthalocyanine tin oxide (SnOPc), titanium phthalocyanine difluoride (TiF) 2 Pc), phthalocyanine tin difluoride (SnF 2 Pc), phthalocyanine indium fluoride (InFPc), phthalocyanine germanium dichloride (GeCl 2 Pc), hexafluorophthalocyanine titanyl (F 16 TiOPc), hexadecafluorophthalocyanine vanadyl (F 16 VOPc), hexafluorophthalocyanine indium chloride (F 16 InClPc), hexafluorophthalocyanine manganese chloride (F 16 MnClPc), hex...

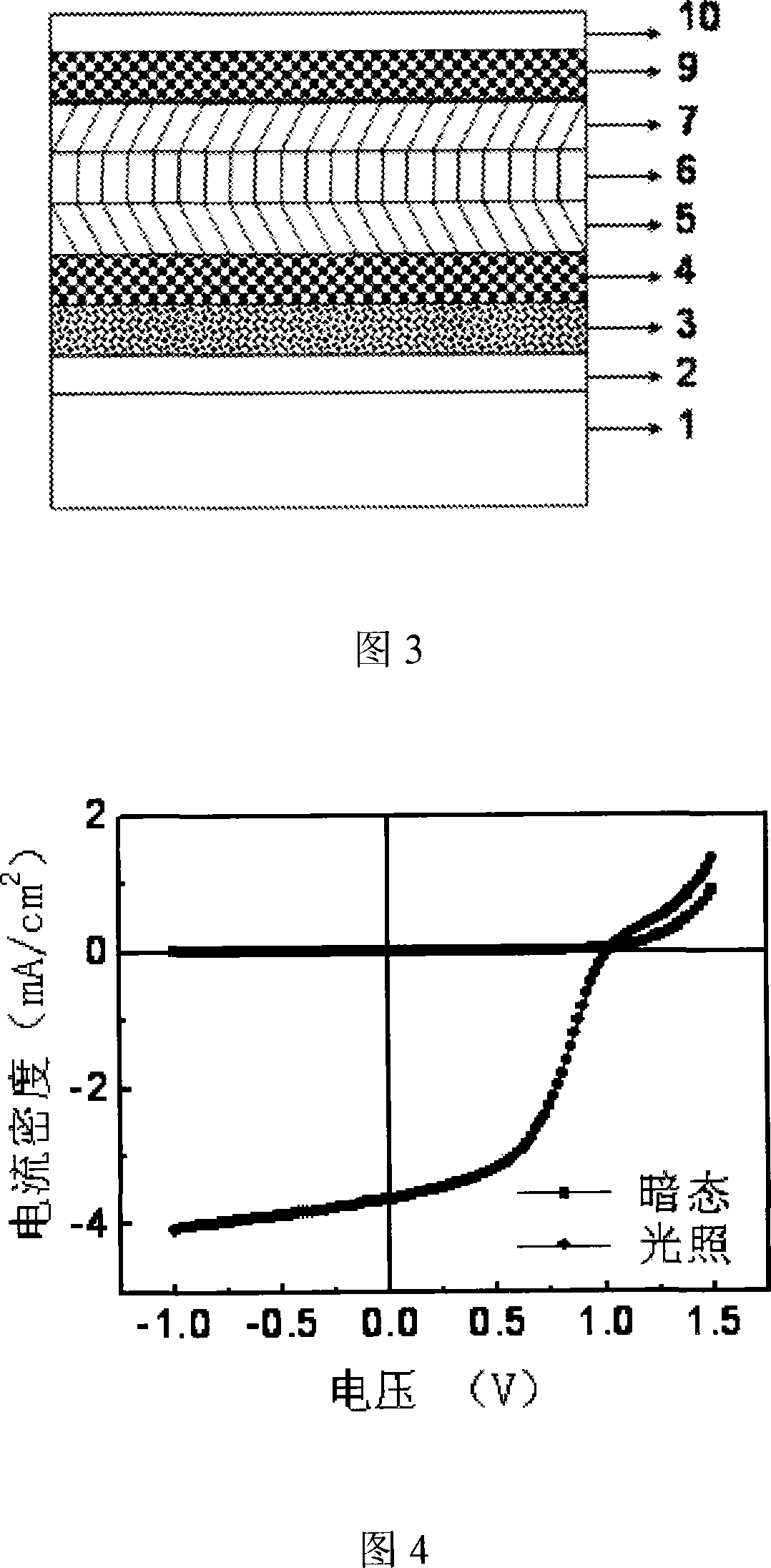

Embodiment 2

[0059] The materials used are the same as in Example 1.

[0060] The device structure adopts the second constitution of the laminated organic photovoltaic cell using the three-layer organic heterojunction film as the intermediate electrode provided by the present invention.

[0061]The specific processing method of the device is as follows: the first semiconductor layer 3 of the first battery and the second semiconductor layer 4 of the first battery are sequentially deposited on the ITO glass 2 by vacuum evaporation; on the second semiconductor layer 4 of the first battery The intermediate electrode layer 5, the intermediate electrode layer 6, and the intermediate electrode layer 7 are sequentially deposited by a vacuum evaporation method, wherein the intermediate electrode layer 7 also serves as the first semiconductor of the second battery; a vacuum evaporation method is used on the intermediate electrode layer 7 The method is followed by the second semiconductor layer 9 of the ...

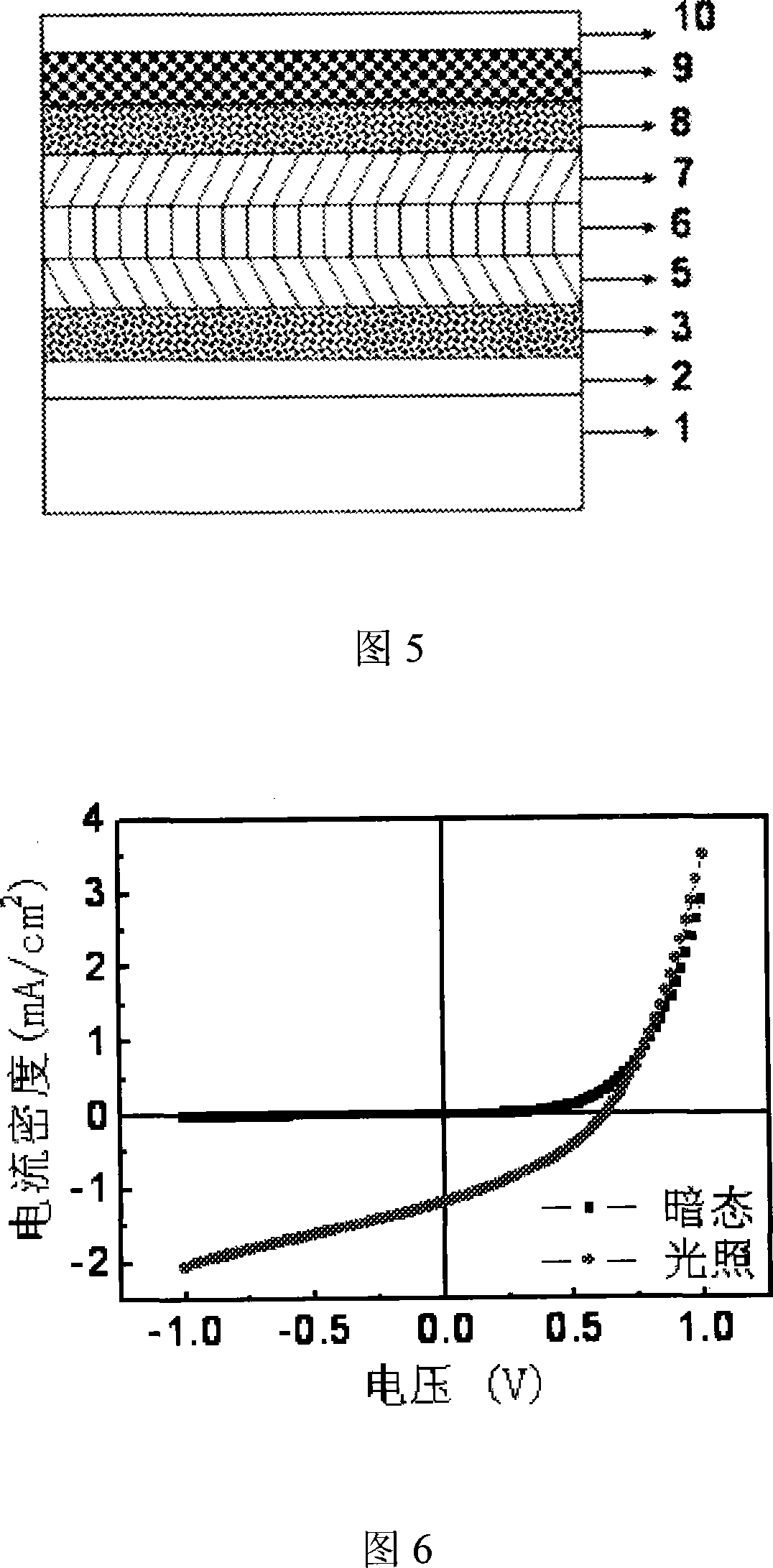

Embodiment 3

[0068] The materials used are the same as in Example 1.

[0069] The device structure adopts the third configuration of the laminated organic photovoltaic cell using three-layer organic heterojunction film as the intermediate electrode provided by the present invention.

[0070] The specific processing method of the device is as follows: the first semiconductor layer 3 of the first battery is deposited on the ITO glass 2 by vacuum evaporation; the middle electrode layer is sequentially deposited on the first semiconductor layer 3 of the first battery by vacuum evaporation 5. The middle electrode layer 6, the middle electrode layer 7; among them, the middle electrode layer 5 serves as the second semiconductor layer of the first battery at the same time; the first semiconductor layer of the second battery is sequentially deposited on the middle electrode 7 by vacuum evaporation method Layer 8 and the second semiconductor layer 9 of the second battery; vacuum evaporation is used on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com