Blue-purple light or blue light excitation fluorophor, preparation method thereof, and packaged white light diode

A blue light excitation and phosphor technology, applied in the field of white light diodes, can solve the problems of uneven composition, instability and toxic hydrolysis conditions of the phosphor, and achieve the effects of stable color coordinates, high manufacturing efficiency and excellent characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

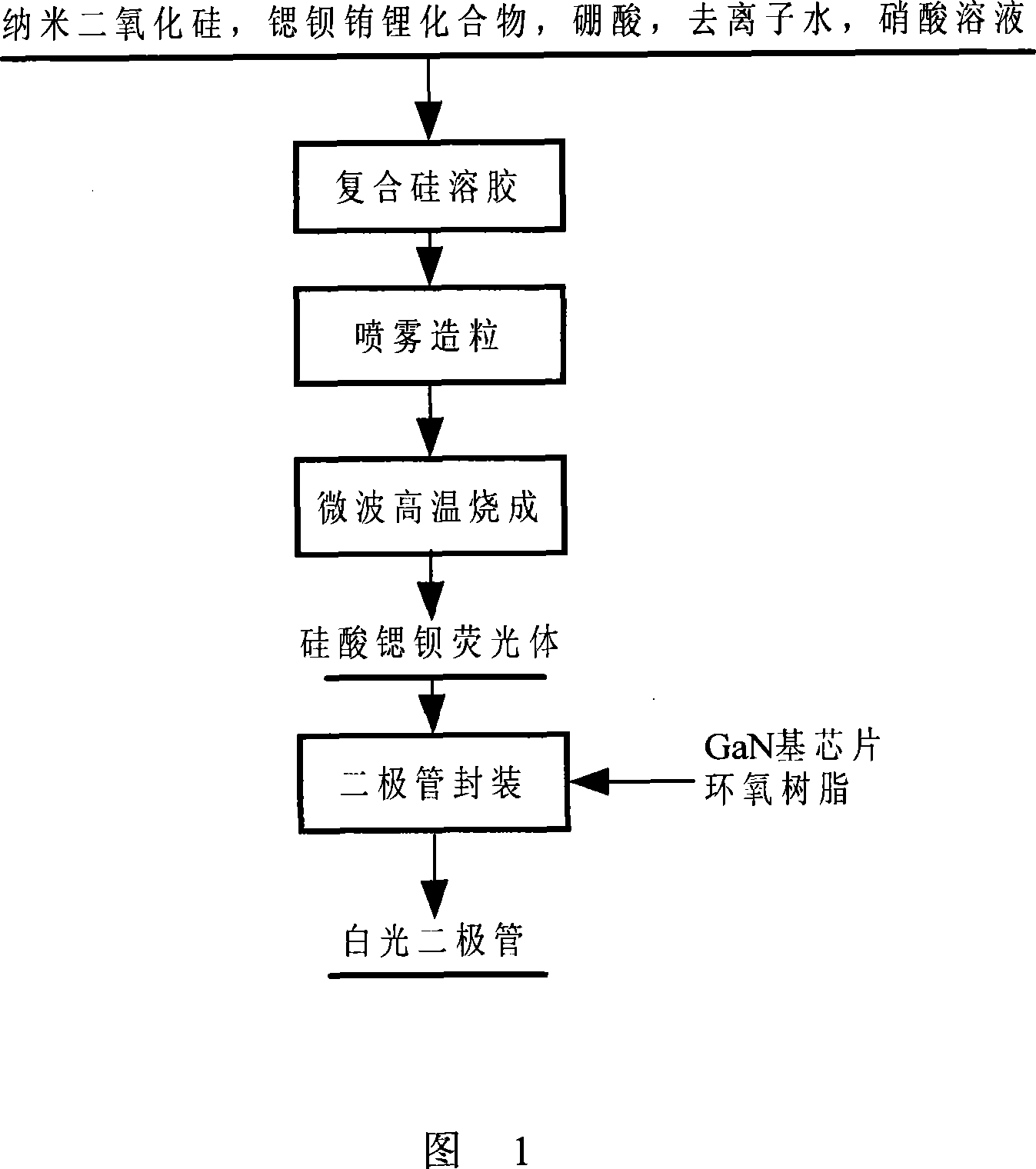

[0026] According to the composition of the phosphor and the process flow of accompanying drawing 1, take a=0.0, b=0.05, c=0.0, d=0.0, e=0.0, take by weighing analytically pure strontium nitrate, the purity is 99.9%, and the average size is 10 nano-SiO 2 Put it in a beaker with spectroscopically pure europium nitrate. According to solid: liquid volume ratio = 1: 10, add deionized water, mechanically stir, titrate to pH = 1 with 30% nitric acid aqueous solution, and stir for 3 hours to obtain a composite silica sol. The composite silica sol is sprayed and granulated, and the compressed air temperature is set to the inlet temperature of 110°C, and the dry air volume is 100m 3 / h, the material flow is 1L / h, to obtain dry gel particles; the dry gel particles are put into a corundum crucible, and pre-fired in an ordinary muffle furnace at a temperature of 600°C for 3 hours, and then naturally cooled to obtain a pre-fired powder. Place the crucible with pre-burned powder in an indu...

Embodiment 2

[0029] According to the composition of phosphor and the technological process of accompanying drawing 1, get a=0.1, b=0.1, c=0.05, d=0.0, c: e=10: 1, take by weighing analytically pure strontium nitrate and barium nitrate, purity 99.9% SiO with an average size of 10 nm 2 and spectrally pure Ce with an average size of 50 nm 2 o 3 , analytically pure lithium nitrate and spectroscopically pure europium nitrate were put into a beaker together. According to solid: liquid volume ratio = 1: 15, add deionized water, mechanically stir, titrate to pH = 2 with 30% nitric acid aqueous solution, and stir for 5 hours to obtain a composite silica sol. The composite silica sol is sprayed and granulated, and the compressed air temperature is set at the inlet temperature of 150°C, and the dry air volume is 150m 3 / h, the material flow is 2L / h, to obtain dry gel particles; the dry gel particles are put into a corundum crucible, and pre-fired in an ordinary muffle furnace at a temperature of 70...

Embodiment 3

[0031] According to the composition of phosphor and the technological process of accompanying drawing 1, get a=0.0, b=0.0, c=0.1, d=0.0, c: e=1: 0.05, take by weighing analytically pure strontium nitrate, purity is 99.9% SiO with an average size of 10 nm 2 and spectrally pure Ce with an average size of 50 nm 2 o 3 , analytically pure lithium nitrate, and put them together in a beaker. According to solid: liquid volume ratio = 1: 20, add deionized water, mechanically stir, titrate to pH = 3 with 30% nitric acid aqueous solution, and stir for 6 hours to obtain a composite silica sol. The composite silica sol is sprayed and granulated, and the compressed air temperature is set at the inlet temperature of 200°C, and the dry air volume is 200m 3 / h, the material flow is 1.5L / h, to obtain dry gel particles; the dry gel particles are put into a corundum crucible, pre-fired in an ordinary muffle furnace, the temperature is 800 ° C, the time is 6 hours, and the pre-fired powder is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com