Method for preparing zinc oxide material

A technology of zinc oxide and raw materials, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of complex process control, high temperature reaction, poor particle uniformity, etc., and achieve good doping uniformity, low reaction temperature and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1.1 Reagents, drugs and instruments

[0026] Instruments: Shimadzu AY220 electronic analytical balance, muffle furnace, XRD-6000X-ray powder diffractometer, NICOLETSXB Fourier transform infrared spectrometer, JSM-5510LV scanning electron microscope.

[0027] Reagents: zinc oxide (analytical grade, Tianjin Kemiou Chemical Reagent Development Center); urea (analytical grade, Sinopharm Chemical Reagent Co., Ltd.).

[0028] 1.2 Experimental process

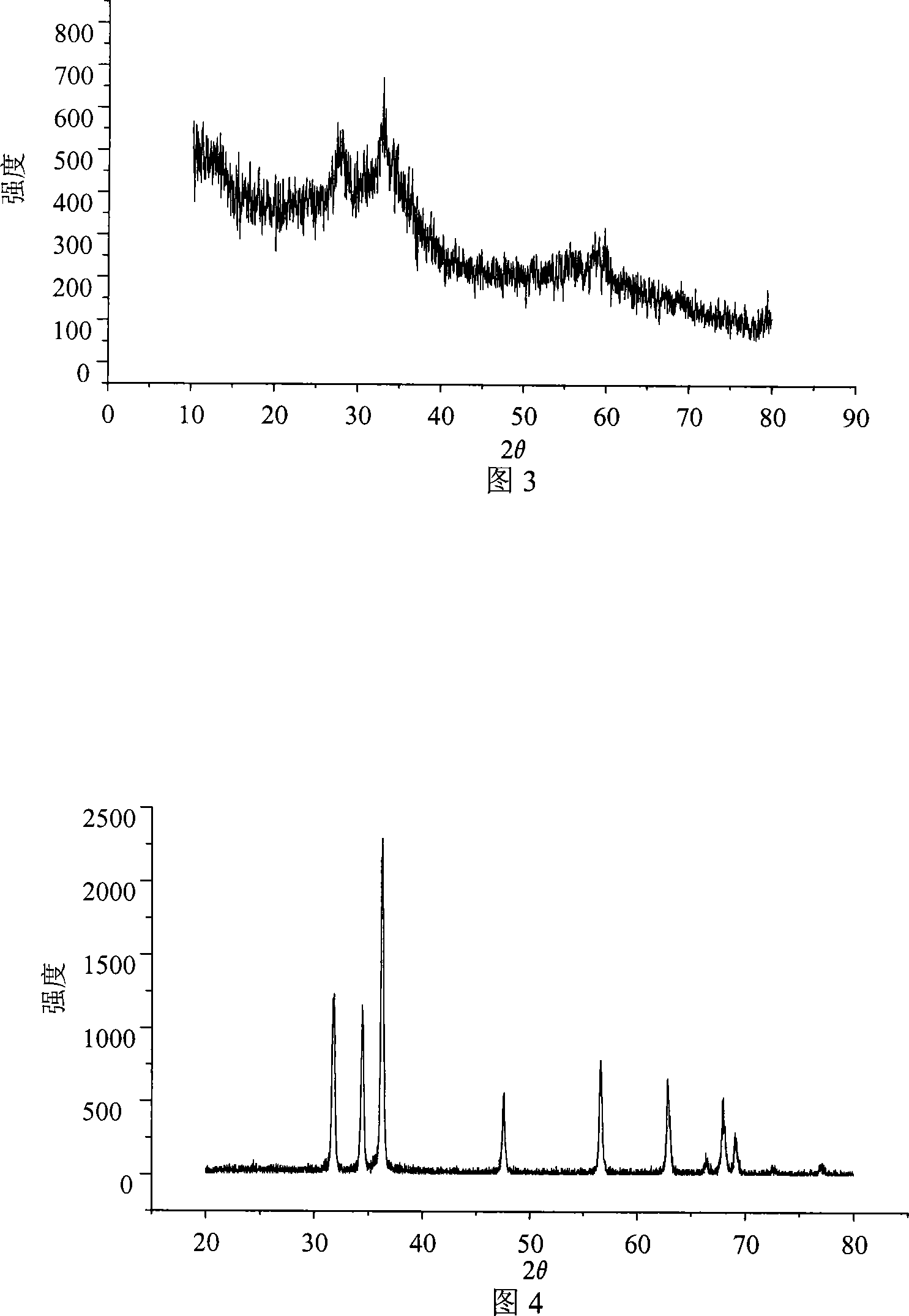

[0029] Mix zinc oxide raw material and urea uniformly in a molar ratio of 1:4, add water to make a rheological state, the molar ratio of zinc oxide raw material to water {ZnO:H 2 O}=0.5, after grinding evenly, a slurry is obtained; the slurry is reacted at 300°C to form a jelly (transparent colloid); the jelly is hydrolyzed under high-speed stirring; the hydrolyzate is thermally decomposed at a temperature of 120°C to obtain white ZnO powder. At 4000~400cm -1 Record the IR spectrum of the hydrolyzate and thermal decompositi...

Embodiment 2

[0038] A preparation method of zinc oxide material, it comprises the steps:

[0039] 1) Selection of raw materials: according to the molar ratio of zinc oxide raw material to urea {ZnO:CO(NH 2 ) 2} is 0.33, the molar ratio of zinc oxide raw material to water {ZnO:H 2 O}=0.3, choose zinc oxide raw material, urea and water, standby;

[0040] 2) mixing the zinc oxide raw material, urea and water, and grinding the mixture evenly to obtain a slurry;

[0041] 3) Heating to gel: heating the slurry obtained in step 2) at 300°C to obtain a transparent gel;

[0042] 4) hydrolysis and thermal decomposition: the colloid obtained in step 3) is hydrolyzed (hydrolyzed with water) at room temperature, filtered to obtain a hydrolyzate containing urea, cyanamide and melamine (wherein cyanamide accounts for more than 70% of the mass fraction of the three products ); heating the filter residue at 120° C. to decompose to obtain a zinc oxide material.

Embodiment 3

[0044] A preparation method of zinc oxide material, it comprises the steps:

[0045] 1) Selection of raw materials: according to the molar ratio of zinc oxide raw material to urea {ZnO:CO(NH 2 ) 2} is 0.25, the molar ratio of zinc oxide raw material to water {ZnO:H 2 O}=0.3, choose zinc oxide raw material, urea and water, standby;

[0046] 2) mixing the zinc oxide raw material, urea and water, and grinding the mixture evenly to obtain a slurry;

[0047] 3) Heating to gel: heating the slurry obtained in step 2) at 300°C to obtain a transparent gel;

[0048] 4) Thermal decomposition: heat the colloid obtained in step 3) to 420° C. and decompose to obtain a zinc oxide material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com