Polyarylene amide sulfides polymers and preparation method thereof

A polyarylene sulfide amide and polymer technology, which is applied in the field of polymer synthesis, can solve the problems of harsh solvent purity, high toxicity of aminothiophenol, unfavorable industrial production, etc., and achieve the effect of low cost, high molecular weight and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

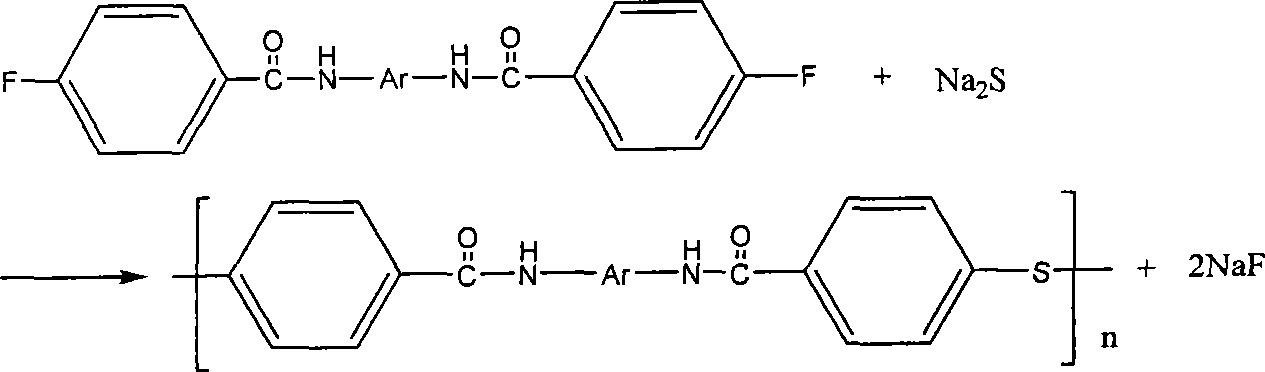

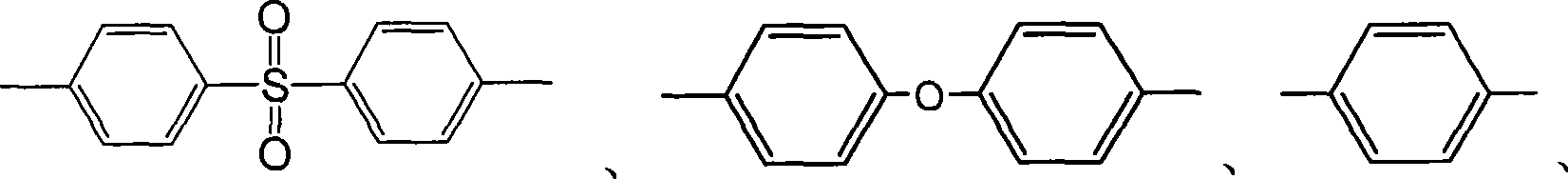

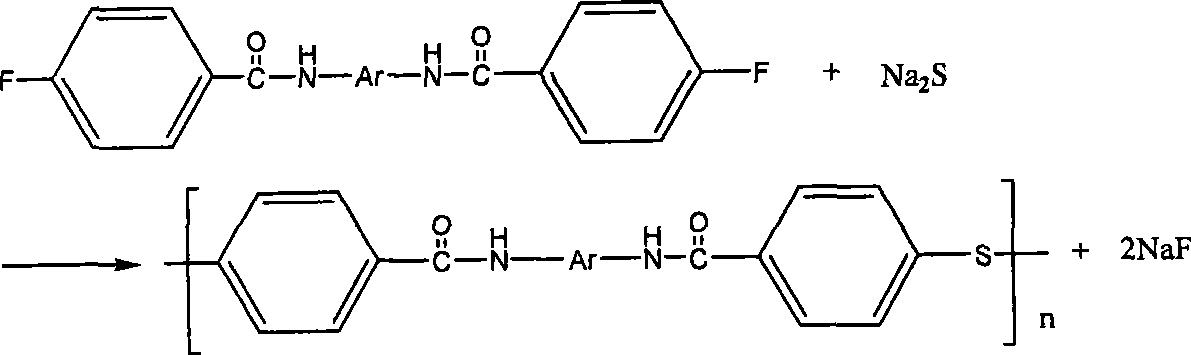

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, with 37.2g 4,4'-diaminodiphenyl sulfone, 30g triethylamine and 200ml tetrahydrofuran, add successively in the reactor that has stirrer, thermometer, dropping funnel, add paraffin in the dropping funnel 55g of fluorobenzoyl chloride, when the temperature drops to -5°C, start to add p-fluorobenzoyl chloride dropwise, finish adding it within 1 hour, keep it for 3 hours, and react at room temperature for 6 hours, pour the above reaction solution Put it into cold water to make it precipitate, wash and filter the precipitate with boiled deionized water, remove water-soluble impurities such as p-fluorobenzoic acid and inorganic salts attached to the monomer, and reflux in methanol for 0.5 hours to further remove p-fluorobenzoic acid , filtered and recrystallized by pyridine to obtain 60.5 g of N,N'-bis(p-fluorobenzoyl)-p-diphenylsulfone diamine with a yield of 82% and a purity of 99.1%.

[0039] Add 1g of lithium chloride, 2g of ε-aminocaproic acid, 1g of potassi...

Embodiment 2

[0040] Embodiment 2, with 37.2g 3,3'-diaminodiphenyl sulfone, 30g triethylamine and 200ml tetrahydrofuran, add successively in the reactor that has stirrer, thermometer, dropping funnel, add paraffin in the dropping funnel 55g of fluorobenzoyl chloride, when the temperature drops to -5°C, start to add p-fluorobenzoyl chloride dropwise, finish adding it within 1 hour, keep it for 3 hours, then react at room temperature for 6 hours, and reduce the above reaction solution to Press and filter, wash and filter the precipitate with boiled deionized water to remove water-soluble impurities such as p-fluorobenzoic acid and inorganic salts attached to the monomer, reflux in methanol for 1 hour to further remove p-fluorobenzoic acid, and filter to obtain 60 g of N,N'-bis(p-fluorobenzoyl)-m-diphenylsulfone diamine was recrystallized from acetone, the yield was 81%, and the purity was 99.3%.

[0041] Add 5g of sodium acetate, 8g of ε-aminocaproic acid, 2g of sodium carbonate, 100g of N-me...

Embodiment 3

[0042]Example 3, add 16.2g m-phenylenediamine, 25g triethylamine and 200ml tetrahydrofuran into the reaction kettle with stirrer, thermometer and dropping funnel in turn, add 47.5g p-fluorobenzoyl chloride to the dropping funnel , when the temperature drops to -5°C, start to add p-fluorobenzoyl chloride dropwise, finish the addition within 1 hour, keep it for 3 hours, and react at room temperature for 6 hours, pour the above reaction solution into cold water to make it Precipitation, the precipitation is washed and filtered with boiling deionized water to remove water-soluble impurities such as p-fluorobenzoic acid and inorganic salts attached to the monomer, recrystallized from methanol, and filtered to obtain N,N'-bis(p-fluorobenzoyl )-m-phenylenediamine 47g, the yield is 89%, and the purity is 99.3%.

[0043] Add 1g of trisodium phosphate, 2g of triphenylphosphine, 0.1g of potassium hydroxide, 300g of N-methylpyrrolidone and 10g of xylene into the reaction kettle with nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com