A magnesium secondary battery anode material and the corresponding preparation method

A technology for magnesium secondary batteries and positive electrode materials, which is applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of insufficient discharge platform stability, poor cycle performance, and no major breakthroughs, and achieves a voltage platform. High, improved integrity, large contact interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Add 1.1 g of nano silicon dioxide to 190 g of water, ultrasonicate for 2 hours, then add 7.9 g of citric acid and 7.0 g of ethylene glycol, and stir vigorously to obtain a suspension;

[0028] (2) 4.1g magnesium acetate tetrahydrate (MgAc 2 4H 2 O) and 4.5g manganese acetate tetrahydrate (MnAc 2 4H 2 O) Dissolve in 50g water respectively to make two solutions, then add to the suspension obtained in step (1), continue to stir for 9 hours, then stir and dry at 60°C for 24 hours to obtain dry gel, namely silicic acid Manganese and magnesium precursors;

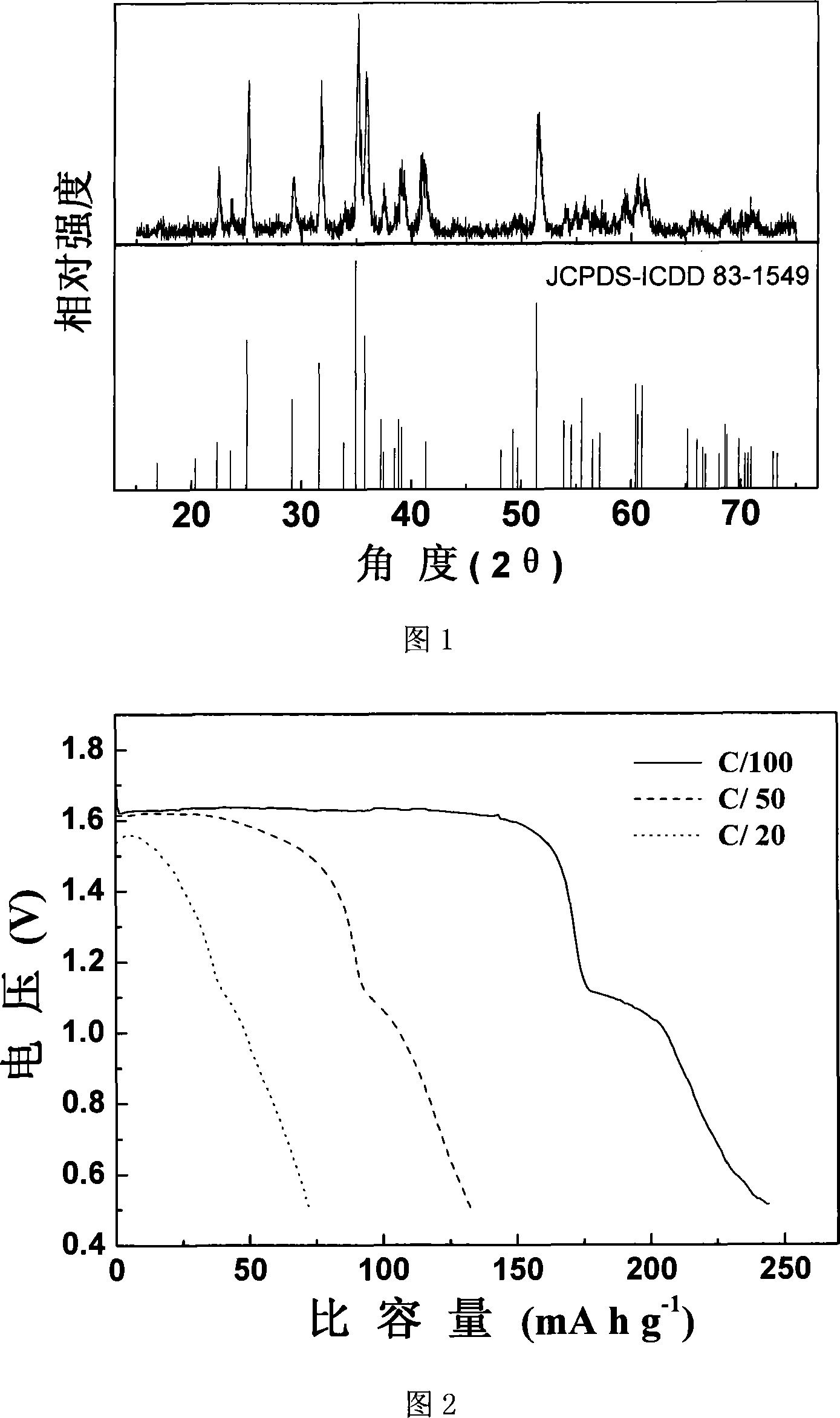

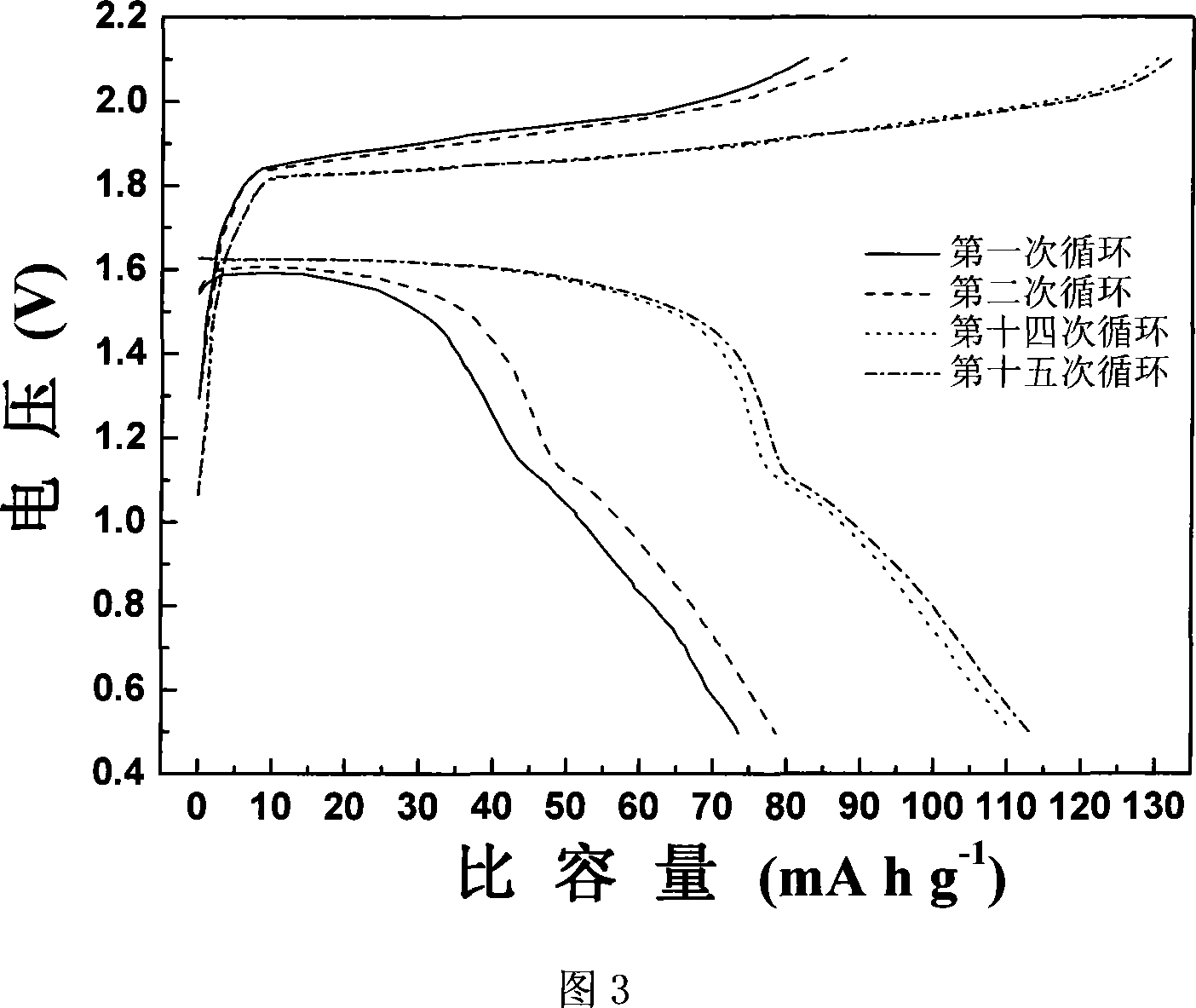

[0029] (3) After the xerogel is pulverized with a mortar, transfer to an agate ball mill jar equipped with an O-ring, add 10g of absolute ethanol as a dispersant, and carry out ball milling. The rotating speed of the high-energy ball mill is 450 rpm. Ball mill for 5 hours, then open the ball mill jar, transfer to a quartz boat after the ethanol volatilizes, heat treat at 750° C. for 48 hours under protective atmosp...

Embodiment 2

[0035] (1) Add 1.1 g of nano-silica to 95 g of water, ultrasonicate for 2 hours, then add 7.9 g of citric acid and 7.0 g of ethylene glycol, and stir vigorously to obtain a suspension;

[0036] (2) 4.1g magnesium acetate tetrahydrate (MgAc 2 4H 2 O) and 4.5g manganese acetate tetrahydrate (MnAc 2 4H 2 O) be dissolved in 60g water respectively to form two solutions, then add to the suspension obtained in step (1), continue to stir for 10 hours, then stir and dry at 60°C for 24 hours to obtain xerogel, i.e. silicic acid Manganese and magnesium precursors;

[0037] (3) After the xerogel is pulverized with a mortar, it is transferred to an agate ball mill jar equipped with an O-ring, 2g of sucrose is added, and 12g of absolute ethanol is added as a dispersant for ball milling. The rotating speed of the high-energy ball mill is 450 rpm, ball milling for 4 hours, then open the ball milling tank, after the ethanol volatilizes, transfer to a quartz boat, heat treatment at 800°C fo...

Embodiment 3

[0043] (1) Add 3.0 g of nano-silica to 400 g of water, ultrasonicate for 3 hours, then add 21.0 g of citric acid and 18.6 g of ethylene glycol, and stir vigorously to obtain a suspension;

[0044] (2) 7.6g magnesium oxalate dihydrate (MgC 2 o 4 2H 2 O) and 8.7g manganese oxalate dihydrate (MnC 2 o 4 2H 2 O) be dissolved in 150g water respectively to form two solutions, then add to the suspension obtained in step (1), continue to stir for 20 hours, then stir and dry at 70°C for 40 hours to obtain dry gel, i.e. silicic acid Manganese and magnesium precursors;

[0045](3) After the xerogel is pulverized with a mortar, transfer it to a ball mill jar equipped with an O-ring, add 8g of β-cyclodextrin, then add 15g of absolute ethanol as a dispersant, and carry out ball milling. The rotating speed is 500 rpm, ball milling for 5 hours, then open the ball milling tank, after the absolute ethanol volatilizes, transfer to a quartz boat, heat treatment at 750°C for 48 hours under pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com