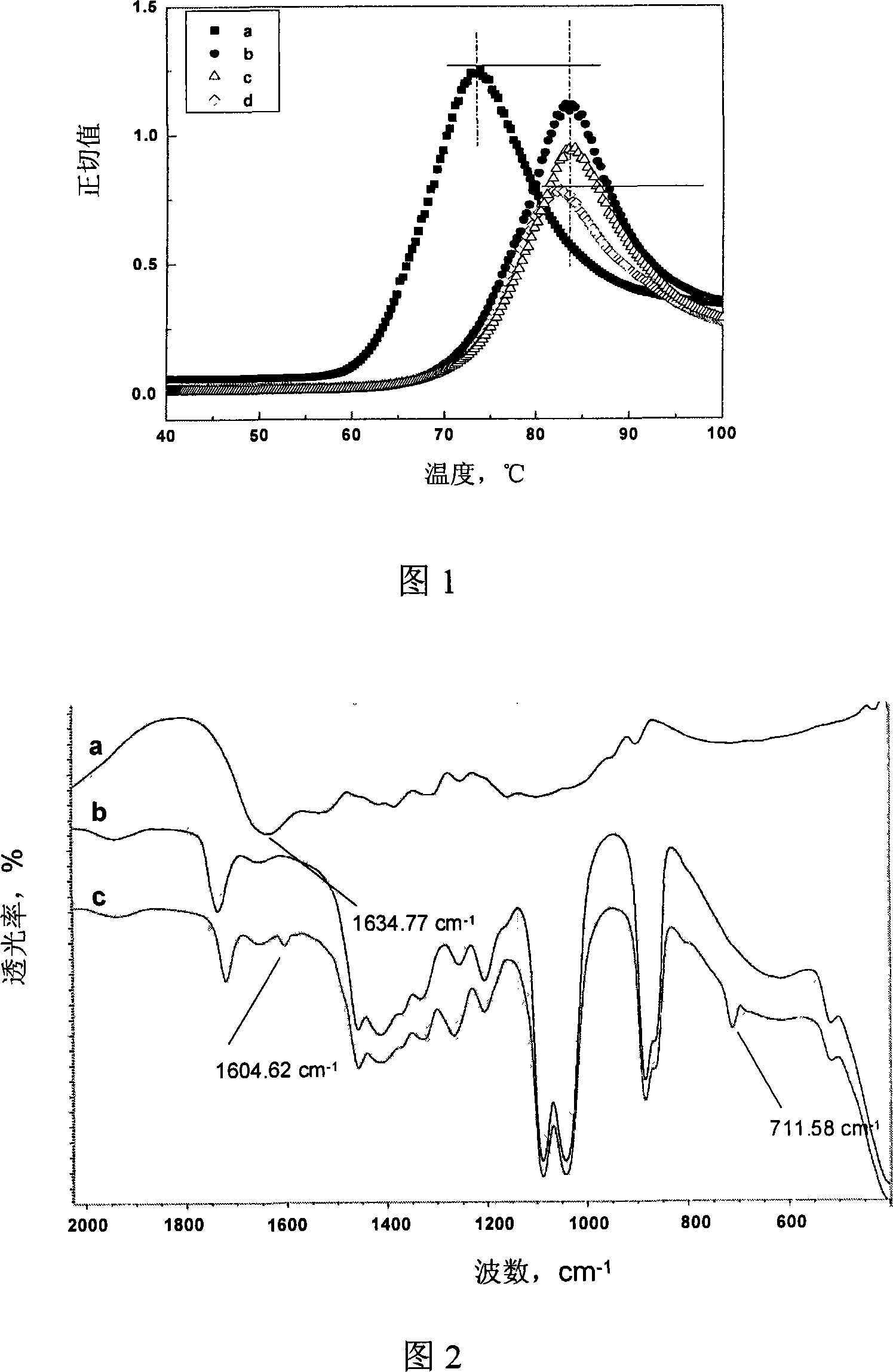

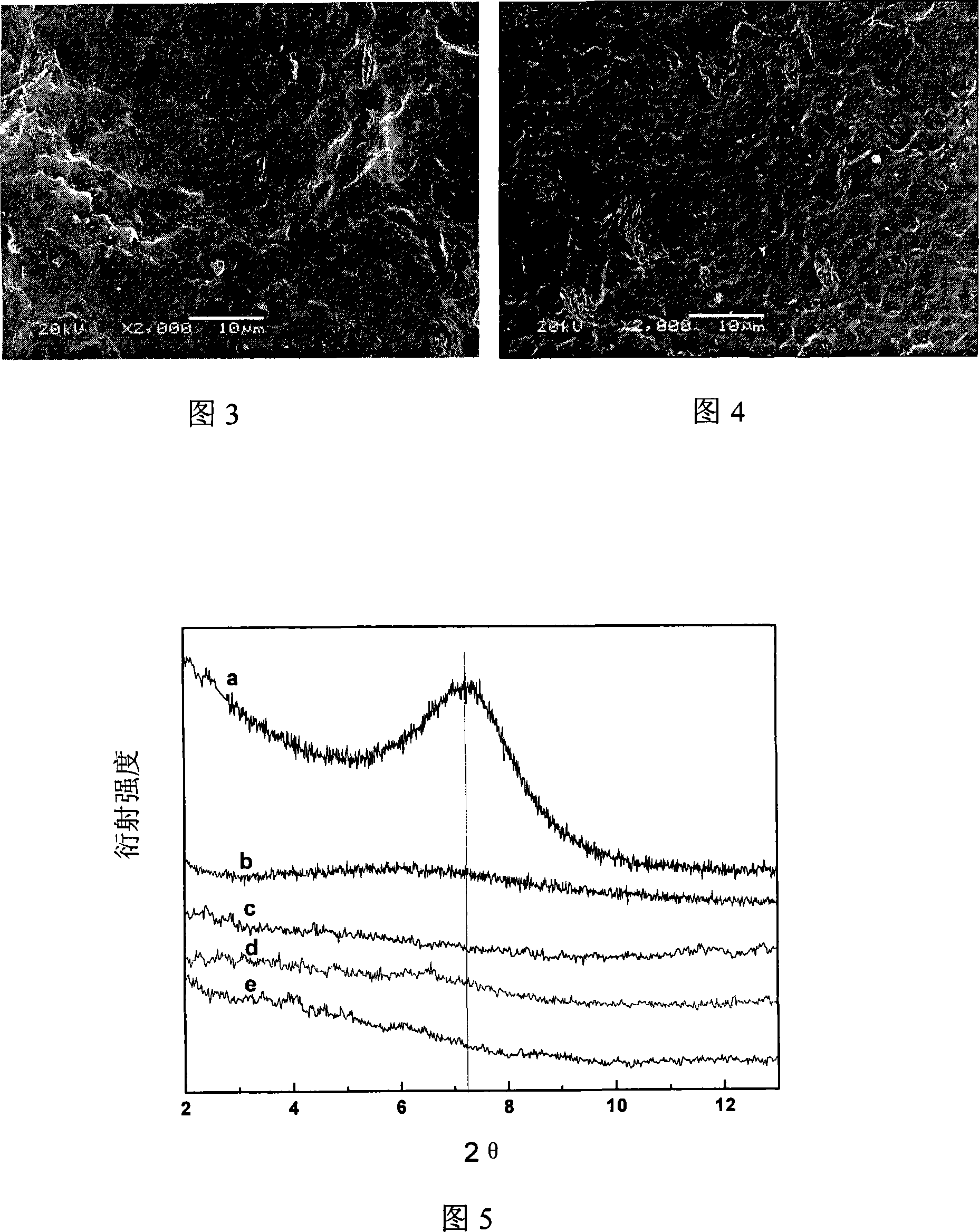

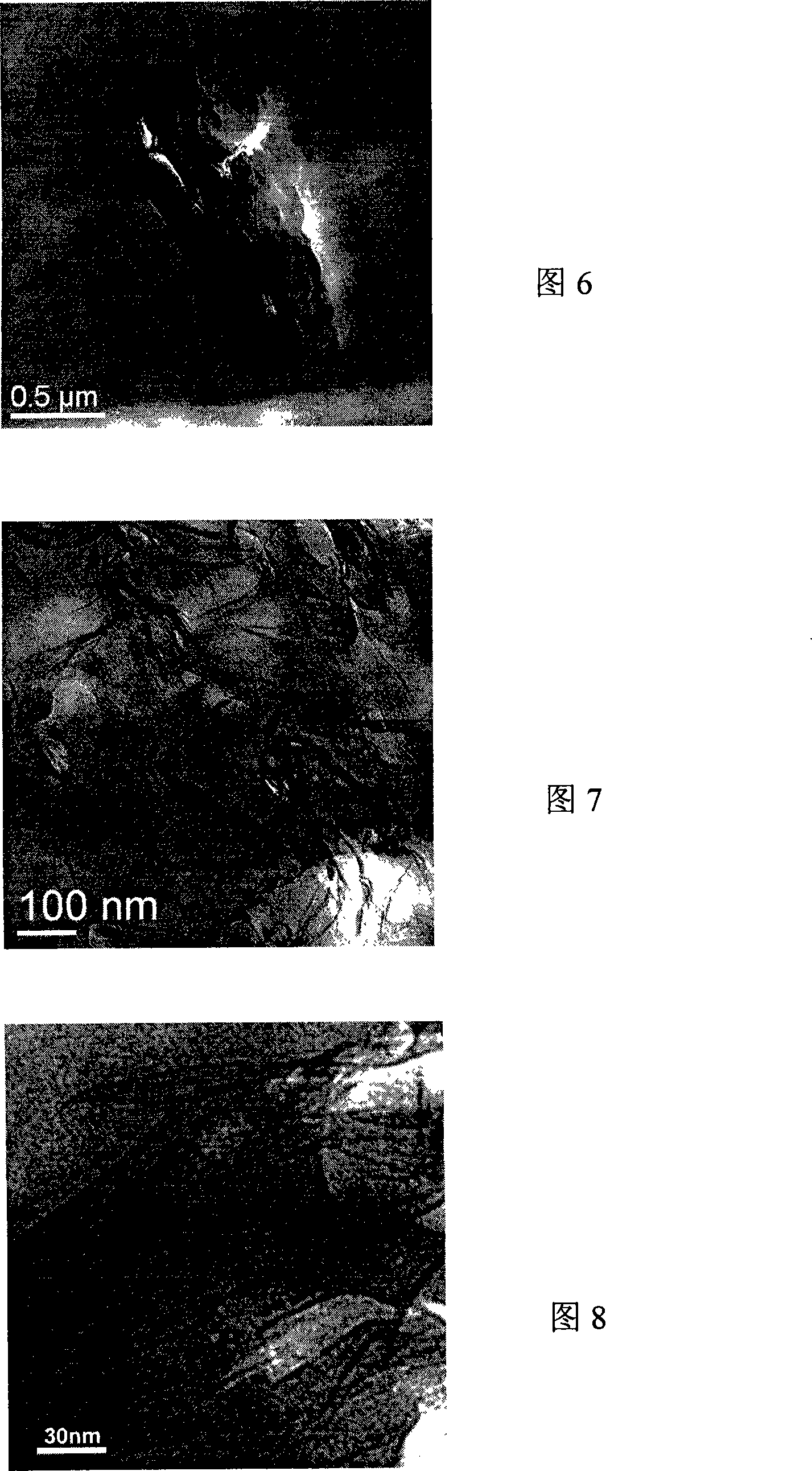

Polyethylene terephthalate/montmorillonite nano composite material and preparation method thereof

A technology of polyethylene terephthalate and nanocomposite materials, which is applied in the field of polyethylene terephthalate/montmorillonite nanocomposite materials and its preparation, can solve the problem of very limited and very limited material performance improvement. It is difficult to obtain exfoliated nanocomposite materials and other problems, and achieve the effect of improving heat resistance and performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The complete mass percentage concentration of dissolving is 1% chitosan hydrochloride (molecular weight is 50000, deacetylation degree 90%, hydrochloride substitution degree 20%) aqueous solution according to the quality of chitosan hydrochloride and montmorillonite The ratio is 1:2, and the ratio is 1:2, and then added dropwise to the aqueous suspension of nano-based montmorillonite with a concentration of 2% by mass, stirred at 50°C for 4 hours, and the solid in the lower layer is removed, and rinsed with hot water until there is no Cl - To prevent ions, dry the obtained solid at <100°C until the water content is 5% to obtain organic montmorillonite;

[0034] Add 3 parts of organic montmorillonite to 138 parts of ethylene glycol based on the amount of untreated montmorillonite, and stir at a temperature of 50°C to obtain a uniformly dispersed ethylene glycol suspension;

[0035] First add 243 parts of terephthalic acid, 0.03% antimony trioxide catalyst and ethylene g...

Embodiment 2

[0037] The complete mass percent concentration of dissolving is 2% chitosan hydrochloride (molecular weight is 70000, deacetylation degree 70%, hydrochloride substitution degree 40%) aqueous solution according to the quality of chitosan hydrochloride and montmorillonite The ratio of 1:1.5 was added dropwise to the calcium-based montmorillonite aqueous suspension with a mass percent concentration of 1%, stirred at 60°C for 5 hours, and the solid in the lower layer was removed, and rinsed with hot water until there was no Cl - To prevent ions, dry the obtained solid at <100°C until the water content is 5% to obtain organic montmorillonite;

[0038] Add 3 parts of organic montmorillonite to 138 parts of ethylene glycol based on the amount of untreated montmorillonite, and stir at a temperature of 60° C. to obtain a uniformly dispersed ethylene glycol suspension;

[0039] Because the proportioning and process conditions of esterification and polymerization are exactly the same as...

Embodiment 3

[0041] The complete mass percentage concentration of dissolving is 3% chitosan hydrochloride (molecular weight is 100000, deacetylation degree 70%, hydrochloride substitution degree 40%) aqueous solution according to the quality of chitosan hydrochloride and montmorillonite The ratio is 1:1 and added dropwise to the sodium-based montmorillonite aqueous suspension with a concentration of 2% by mass, stirred at 60°C for 5 hours, and the solid in the lower layer is removed, and rinsed with hot water until there is no Cl - To prevent ions, dry the obtained solid at <100°C until the water content is 20% to obtain organic montmorillonite;

[0042] Add 3 parts of organic montmorillonite to 138 parts of ethylene glycol based on the amount of untreated montmorillonite, and stir at a temperature of 60° C. to obtain a uniformly dispersed ethylene glycol suspension;

[0043] Because the proportioning and process conditions of esterification and polymerization are exactly the same as thos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com