Method for extracting garlic oil

An extraction method and garlic oil technology, applied in the field of garlic oil extraction and production, can solve the problems of inability to obtain pure garlic oil, lack of attention, waste of resources and the environment, and achieve comprehensive processing and utilization, reduce dissolution and impact, The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

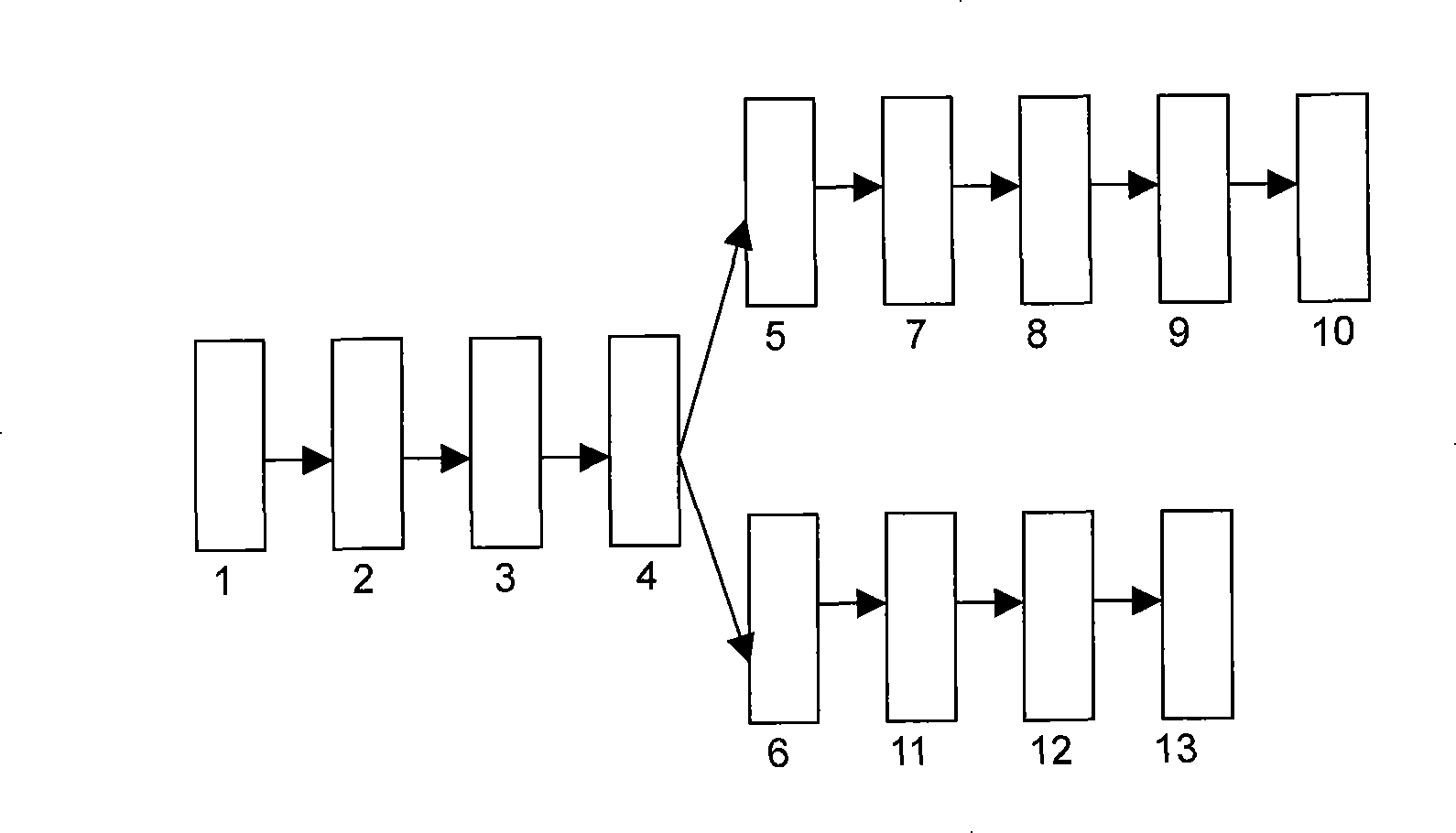

Method used

Image

Examples

Embodiment 1

[0021] (1) Get mildew-free garlic and peel it through a peeler; add one volume of water and crush it to a particle size of 0.1 mm with a homogenizer;

[0022] (2) obtain garlic juice and garlic dregs by pressing with an extruder;

[0023] (3) Add 6 times the volume of n-hexane to the garlic juice and extract at 30°C for 3 hours;

[0024] (4) Take the extracted organic phase and use an organic membrane with a molecular weight of 1500Da, filter it at a pressure of 0.5 MPa and a temperature of 25° C., and collect the permeate;

[0025] (5) The permeate is concentrated to obtain garlic oil; the concentration temperature is 30°C.

[0026] (6) The obtained in step 2 is freeze-dried by a freeze dryer to obtain food-grade garlic powder.

Embodiment 2

[0028] (1) Get mildew-free garlic, peel it through a peeling machine; add one volume of water, and synchronously crush it to a particle size of 0.05mm with a colloid mill and ultrasonic waves (controlling ultrasonic frequency 25KHz);

[0029] (2) obtain garlic juice and garlic dregs by pressing with an extruder;

[0030] (3) Add 1 volume of petroleum ether to the garlic juice and extract at 45°C for 1.5 hours;

[0031] (4) Take the extracted organic phase and use an organic membrane with a molecular weight cut-off of 300Da, filter it at a pressure of 0.1 MPa and a temperature of 35° C., and collect the permeate;

[0032] (5) The permeate was concentrated under reduced pressure to obtain garlic oil; the concentration under reduced pressure was at a temperature of 55°C.

[0033] (6) Keep the garlic residue obtained in step 2 at 20° C. for 6 hours, and freeze-dry using a freeze dryer to obtain food-grade garlic powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com