Composite distillation film and preparation method and application thereof

A distillation membrane and membrane distillation technology, applied in chemical instruments and methods, pervaporation, membrane technology, etc., can solve the problems of prolonging the working time of the distillation membrane, and achieve good anti-pollution, extended working time, and good anti-pollution performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The preparation method of the composite distillation membrane designed by the present invention is characterized in that the preparation method is as follows: first carry out the functional finishing on the textile support body of the present invention, and then carry out single-sided finishing on one side of the functionally finished textile support body Coating, after coating the casting solution, immerse the textile support coated with the casting solution into the coagulation bath to make the casting solution phase-separated, and obtain a hydrophobicity with separation effect on the textile support through the phase inversion method. The polymer microporous membrane layer can be used to prepare the composite distillation membrane. The thickness of the microporous membrane is required to be 5-100 μm, and the required thickness of the microporous membrane layer can be obtained by adjusting the distance between the scrapers of the coating equipment.

[0014] Since the ...

Embodiment 1

[0021] The textile support of the distillation membrane is made of polyester filament taffeta fabric with a weight of 79g / m 2 . The textile support is finished with water and oil repellent finishing agent FK 510, the dosage of the finishing agent is 0.1-3g / L, and the technological process is: padding→drying→baking.

[0022] The polymer used for the coating film is polyvinylidene fluoride (0.9 Pa·s, 0.1 g / mL DMAC), and the formula of the casting film is: polyvinylidene fluoride 12%, dimethylformamide 85%, LiCl 3%.

[0023] The preparation of the distillation membrane in this example adopts the method of single-sided coating, and evenly coats a layer of casting liquid on one side of the textile support after the above-mentioned functional finishing, and then immerses the textile support coated with the casting liquid into In the coagulation bath, the casting solution is phase-separated to form a membrane, so that a polymer microporous membrane layer with separation effect is ob...

Embodiment 2

[0030]The functional finishing of the textile support of the distillation membrane is done by polyvinyl alcohol and citric acid. The composition of the finishing solution is as follows: polyvinyl alcohol 40g / L, glyoxal 2g / L, citric acid 2g / L, and the process is: padding→drying Dried → baked. All the other are with embodiment 1.

[0031] After inspection, the breaking strength of the distillation film is 685N / 5cm, the peeling strength is 25cN / cm, and the moisture permeability is 6.5kg / m 2 · 24h (38°C, relative humidity 90%).

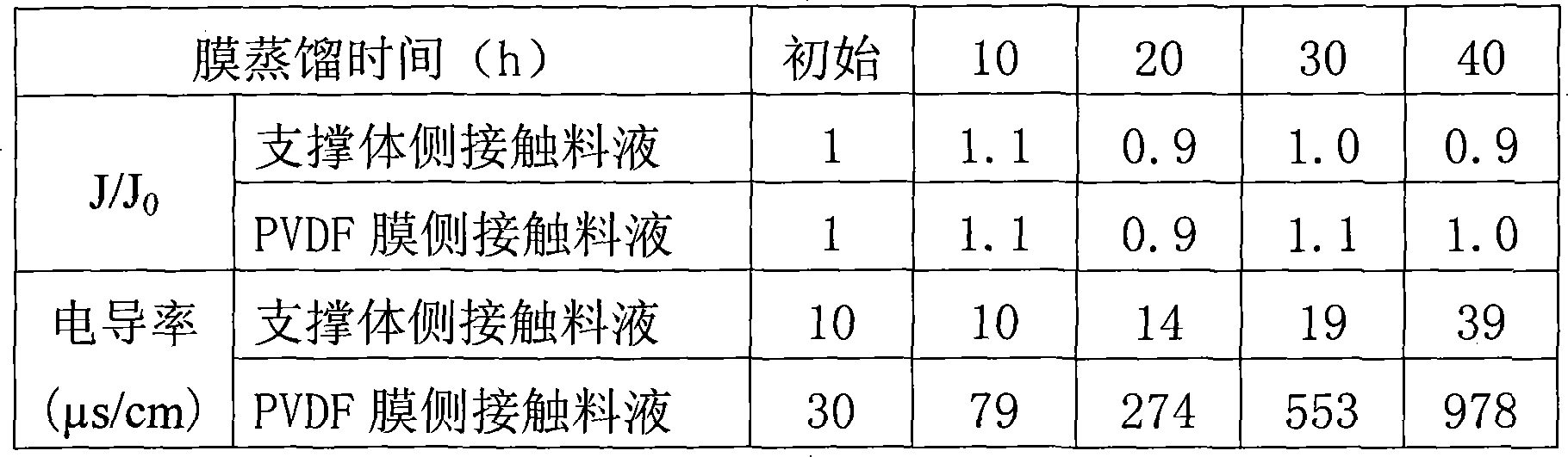

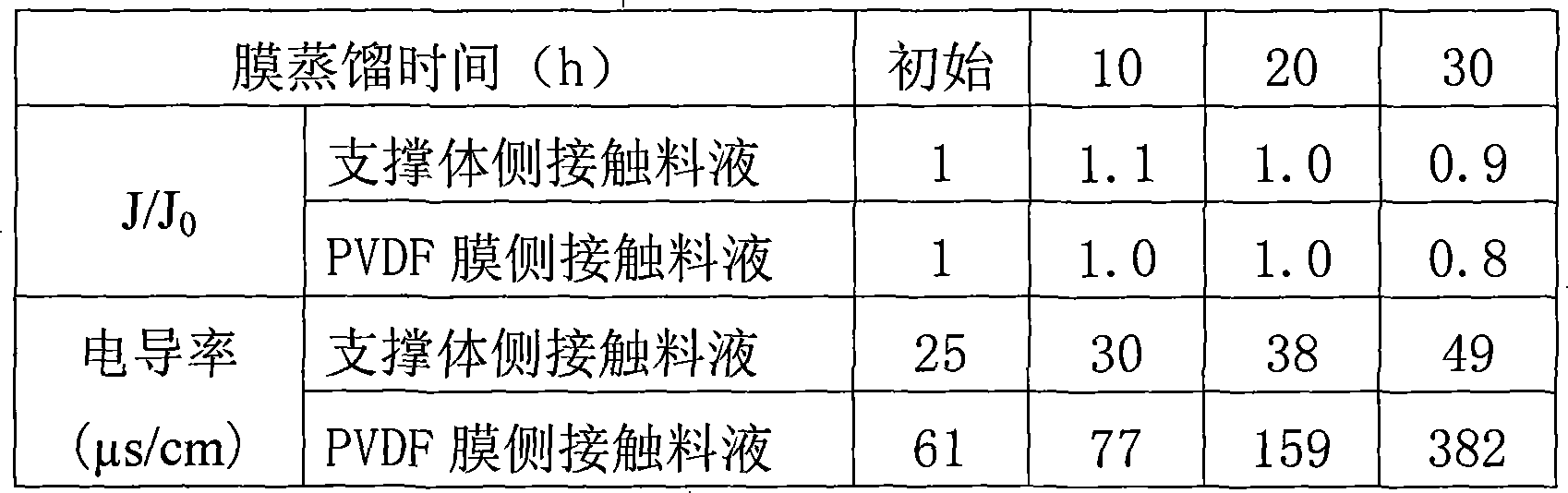

[0032] When the distillation membrane is used for air-gap membrane distillation of the alkaline saturated solution of humic acid, the membrane distillation is carried out in such a way that the textile support side of the distillation membrane of this embodiment and the side of the PVDF microporous membrane are in contact with the feed liquid. Concentration of feed solution, relative membrane flux J / J 0 (J 0 is the initial membrane flux) and the condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com