Formaldehyde-phenol resin derivative and preparation method thereof

A technology for phenolic resins and derivatives, applied in the field of phenolic resin derivatives and their preparation, can solve the problems of phenolic resins being easy to absorb and increase in viscosity, and achieve the effects of low hydrolyzable chlorine content, low water absorption, and low ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

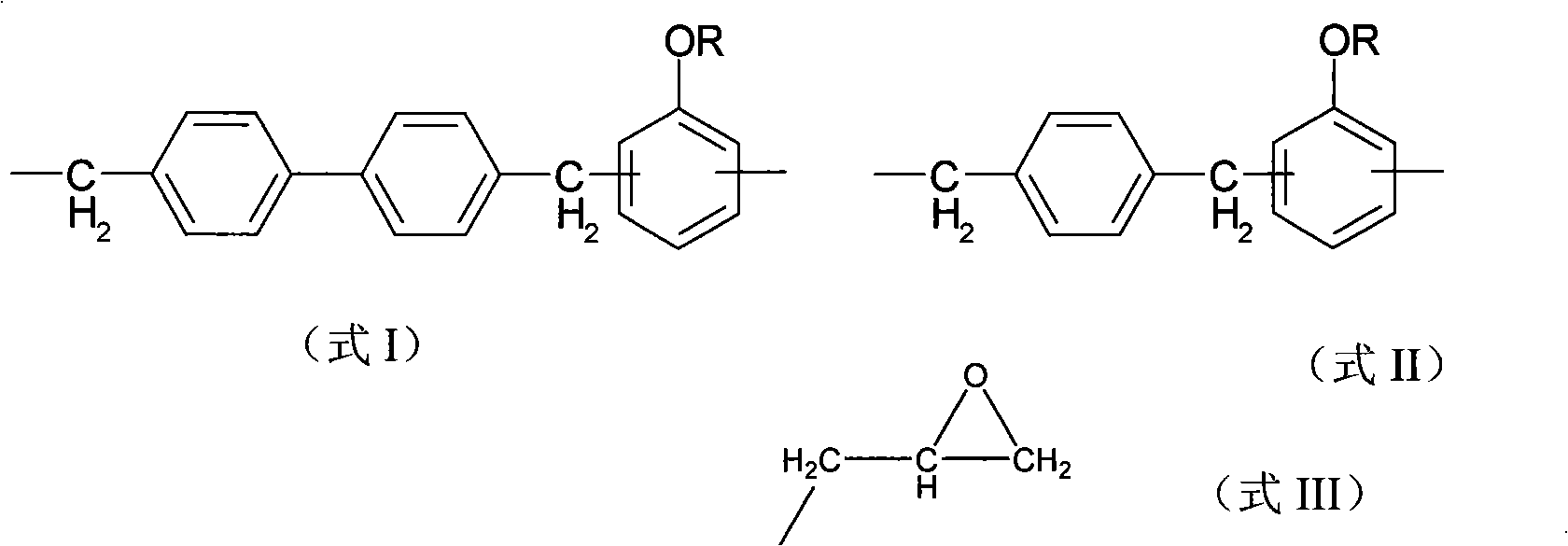

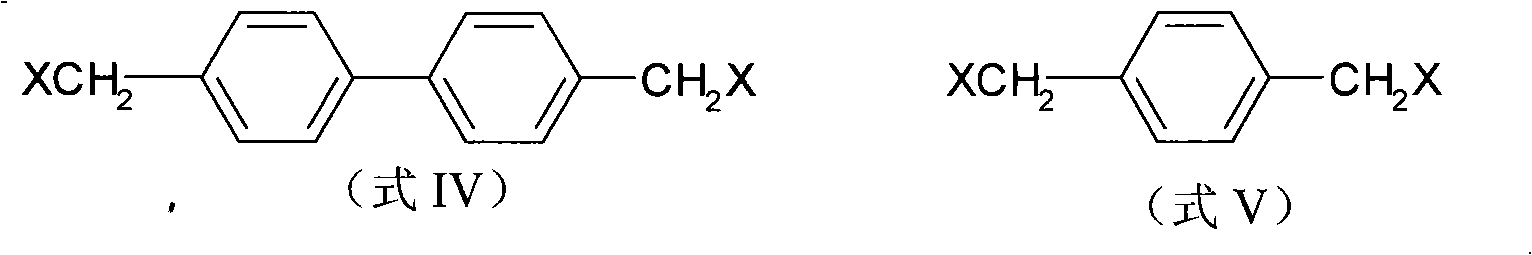

[0023] Preparation of phenolic resin derivatives. The resin provided by the present invention, when R is H, is a kind of phenolic resin, which can be prepared by condensation reaction of phenol of formula IV, phenol and biphenyl derivatives of formula V under acid catalysis; when R is of formula III When the epoxy substituent is used, it is a novolac epoxy resin, which can be prepared by epoxidizing the phenolic resin with halogenated propylene oxide. The method prepared by the invention is a kind of random copolymer, and various chain unit units are randomly arranged in the main chain of the polymer.

[0024] In the preparation process of phenolic resin, a water separator can be used to separate and remove water, alcohol and the like generated in the reaction process through a water separator, so as to promote a more complete and faster reaction; Remove the catalyst acid of the reaction system or the acid produced by the reaction, and then distill off the solvent and unreact...

Embodiment 1

[0027] Into a flask equipped with thermometer, nitrogen inlet, water trap, condenser, stirrer, add 270 g of 4,4'-bis(ethoxymethyl)biphenyl, 19 g of 4,4'-bis(ethoxy Base methyl) phenylene and 310 grams of phenol, heated under nitrogen protection, started stirring, all solids were dissolved to form a homogeneous liquid. Slowly add 1 g of p-toluenesulfonic acid to the above reaction liquid so that the liquid temperature does not exceed 50°C. Heating to raise the reaction temperature to 120°C, during which the color of the reaction solution deepened and began to boil. The by-product ethanol formed during the reaction was separated and removed with a water separator, and the reaction was stirred at 120° C. for 5 hours. After the reaction is complete, cool to room temperature; add 1000 grams of methyl isobutyl ketone to the reaction solution, mix and stir evenly; in a separatory funnel, wash the organic liquid with 300 grams of deionized water. Repeat washing until the washing liq...

Embodiment 2

[0029] Add 300 g of 4,4'-bis(propoxymethyl)biphenyl, 19 g of 4,4'-bis(ethoxy Base methyl) phenylene and 310 grams of phenol, heated under nitrogen protection, started stirring, all solids were dissolved to form a homogeneous liquid. Slowly add 1 g of p-toluenesulfonic acid to the above reaction liquid so that the liquid temperature does not exceed 50°C. Heating to raise the reaction temperature to 120°C, during which the color of the reaction solution deepened and began to boil. The by-products ethanol and propanol formed during the reaction were separated and removed by a water separator, and the reaction was stirred at 120° C. for 5 hours. After the reaction is complete, cool to room temperature; add 1000 grams of methyl isobutyl ketone to the reaction solution, mix and stir evenly; in a separatory funnel, wash the organic liquid with 300 grams of deionized water. Repeat washing until the washing liquid is neutral. Separate the organic phase and dry it; remove the solvent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com