Biological heap leaching metal technique for low grade unwieldiness gold ore

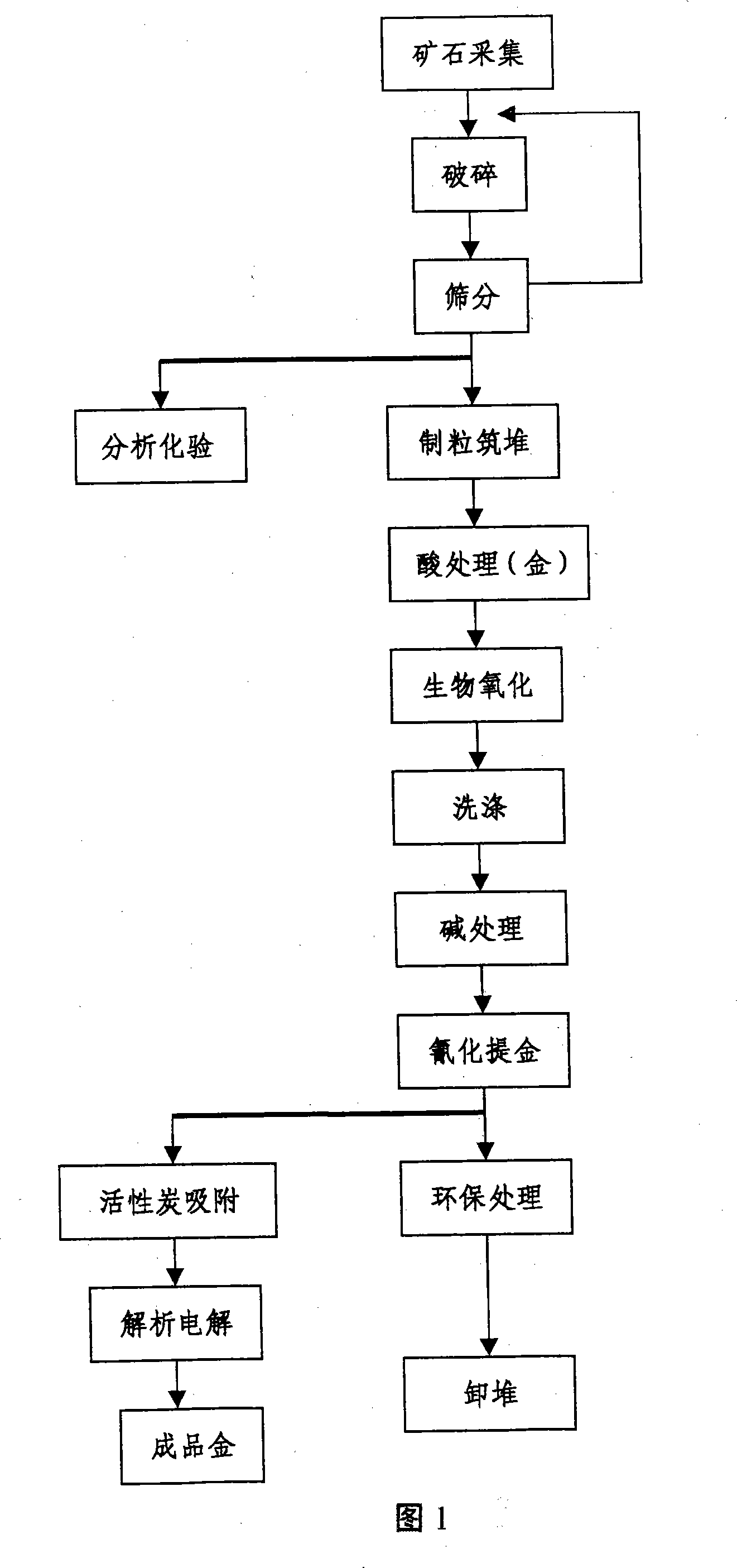

A technology for refractory gold mines and biological heaps, which is applied in the gold leaching process of oxidation pretreatment of gold-bearing minerals by using exclusive gold ore microorganisms, and in the field of bioheap leaching gold extraction technology, which can solve the problem of high cost of recovery process and long process flow , Difficult to deal with gold ore and other problems, to achieve the effect of increasing production safety, short process flow and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention is applied to a low-grade refractory gold mine in Liaoning Province. The average ore grade is 2.99g / t. The metal mineral composition in the ore is mainly metal sulfide minerals. The analysis and measurement results of the ore mineral composition are shown in Table 1.

[0026] Table 1 Analysis and measurement results of ore mineral composition of a low-grade refractory gold mine in Liaoning Province

[0027] metal minerals

gangue minerals

mineral name

Average content (%)

mineral name

Average content (%)

5.62

66.00

1.24

18.00

chalcopyrite, tetrahedrite

0.10

2.90

0.07

2.70

0.03

1.02

other

2.32

Total Metal Minerals

7.06

Total gangue minerals

92.94

[0028] From t...

Embodiment 2

[0046] The present invention is applied to the low-grade refractory gold mine in Wushan, the average ore grade of which is 2.34g / t, and the analysis and measurement results of the mineral composition of the ore are shown in Table 2.

[0047] Table 2 Analysis and measurement results of ore mineral composition of Wushan low-grade refractory gold mine

[0048] metal minerals

Relative content (%)

mineral name

Average content (%)

3.07

76.07

0.49

0.23

8.55

0.38

garnet

8.66

0.01

Tetrahedrite, Chalcocite, Bornite

0.11

0.40

0.46

other

1.62

white lead ore

trace

total

4.75

95.25

[0049] According to the characteristics of the ore, the ore proc...

Embodiment 3

[0067] The present invention is applied to a low-grade refractory gold mine in Yunnan, where the gold grade is 1.5g / t, and the analysis and measurement results of the mineral composition of the ore are shown in Table 3.

[0068] Table 3 Mineral composition analysis and measurement results of a low-grade refractory gold mine in Yunnan

[0069] metal minerals

gangue minerals

mineral name

Average content (%)

mineral name

Average content (%)

1.08

73.88

Arsenopyrite, orthorhombic arsenite

0.48

9.45

0.09

5.80

0.03

4.90

0.03

1.32

0.32

other

2.38

0.14

Total Metal Minerals

2.17

Total gangue minerals

97.83

[0070] According to the characteristics of the ore, the gol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com