Rumen bypass becholine microcapsule and preparation technique

A technology of choline chloride and preparation process, which is applied in the directions of microcapsules, capsule transportation, and animal feed molding or processing, can solve the problems such as exposure of compressed and deformed capsule cores, influence product absorption, deformation and rupture, etc., and achieve coating The effect of uniform thickness, increased absorption rate and rounded particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

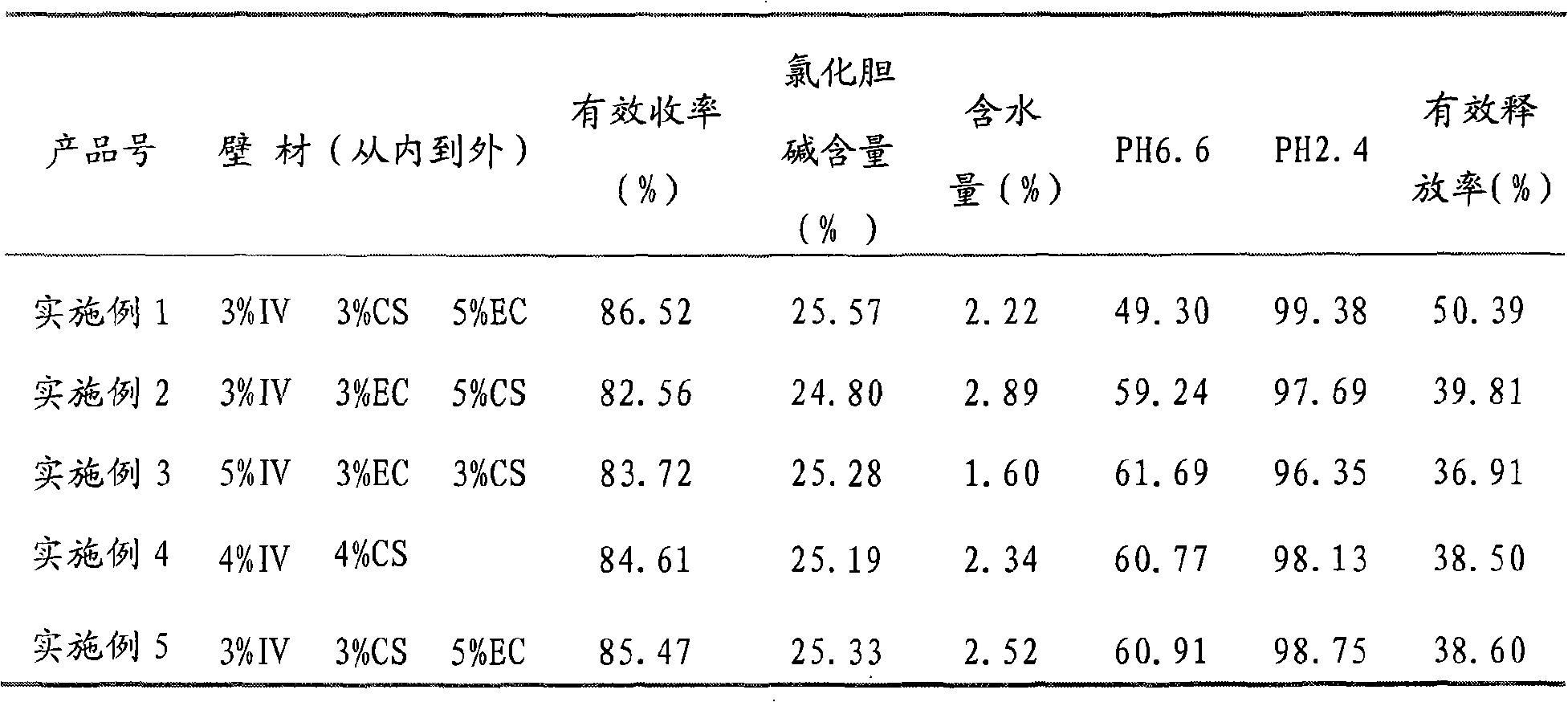

Embodiment 1

[0025] 1. Core material preparation:

[0026] Choline chloride 40kg, starch 10kg, microcrystalline cellulose 5kg, footstone 45kg and 1.5% sodium carboxymethylcellulose aqueous solution 30000ml are mixed in proportion, then granulated by a swing granulator, and then shot blasted by a shot blasting machine. Dry (equipment: FLP type fluidized granulation coating dryer), sieve, the particle size of the sieve is between 16-40 mesh, set aside.

[0027] 2. Preparation of coating solution:

[0028] Add 12g acrylic resin IV to every 100ml95% alcohol solution, stir to make it dissolve to make acrylic resin IV solution; add 3g chitosan to every 100ml4% acetic acid solution, stir to make it dissolve to make chitosan solution; Add 2.5g of ethyl cellulose to the solution, stir to make it dissolve to make ethyl cellulose solution.

[0029] 3. Preparation of microcapsules:

[0030] The above-mentioned granular core material is sent into the coating chamber of the fluidized bed,

[0031] (...

Embodiment 2

[0035] 1. Core material preparation:

[0036] Choline chloride 35kg, starch 5kg, microcrystalline cellulose 10kg, footstone 50kg, 1.5% sodium carboxymethylcellulose aqueous solution 30000ml are mixed in proportion, and all the other are with embodiment 1.

[0037] 2. Preparation of coating solution:

[0038] With embodiment 1.

[0039] 3. Preparation of microcapsules:

[0040] Send the above-mentioned granular core material into the coating chamber of the fluidized bed, and spray acrylic resin IV solution, ethyl cellulose solution, chitosan in sequence in the order of inner layer coating, additional layer coating, and outer layer coating. solution, wherein, the spraying amount of the inner layer coating is 3% of the mass of the core material as the acrylic resin IV after drying as the inner layer coating, and the spraying amount of the additional layer coating is that of ethyl cellulose after drying as the additional layer coating Clothing is 3% of core material quality, an...

Embodiment 3

[0042] 1. Core material preparation:

[0043] Choline chloride 45kg, starch 8kg, microcrystalline cellulose 7kg, footstone 40kg, 1.5% sodium carboxymethylcellulose aqueous solution 30000ml are mixed in proportion, and all the other are with embodiment 1.

[0044] 2. Preparation of coating solution:

[0045] With embodiment 1.

[0046] 3. Preparation of microcapsules:

[0047] Send the above-mentioned granular core material into the coating chamber of the fluidized bed, and spray acrylic resin IV solution, ethyl cellulose solution, chitosan in sequence in the order of inner layer coating, additional layer coating and outer layer coating Solution, wherein, the spraying amount of the inner layer coating is the dried acrylic resin IV as the inner layer coating is 5% of the core material quality, and the spraying amount of the outer layer coating is the dried chitosan as the outer layer coating 3% of the mass of the core material, the spraying amount of the additional layer coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com