Preparation method of banana natural resistance starch

A technology for resistant starch and banana is applied in the field of preparation of natural banana resistant starch to achieve the effects of solving technical barriers, improving consistency, improving food quality and processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of Banana Natural Resistant Starch Finished Product

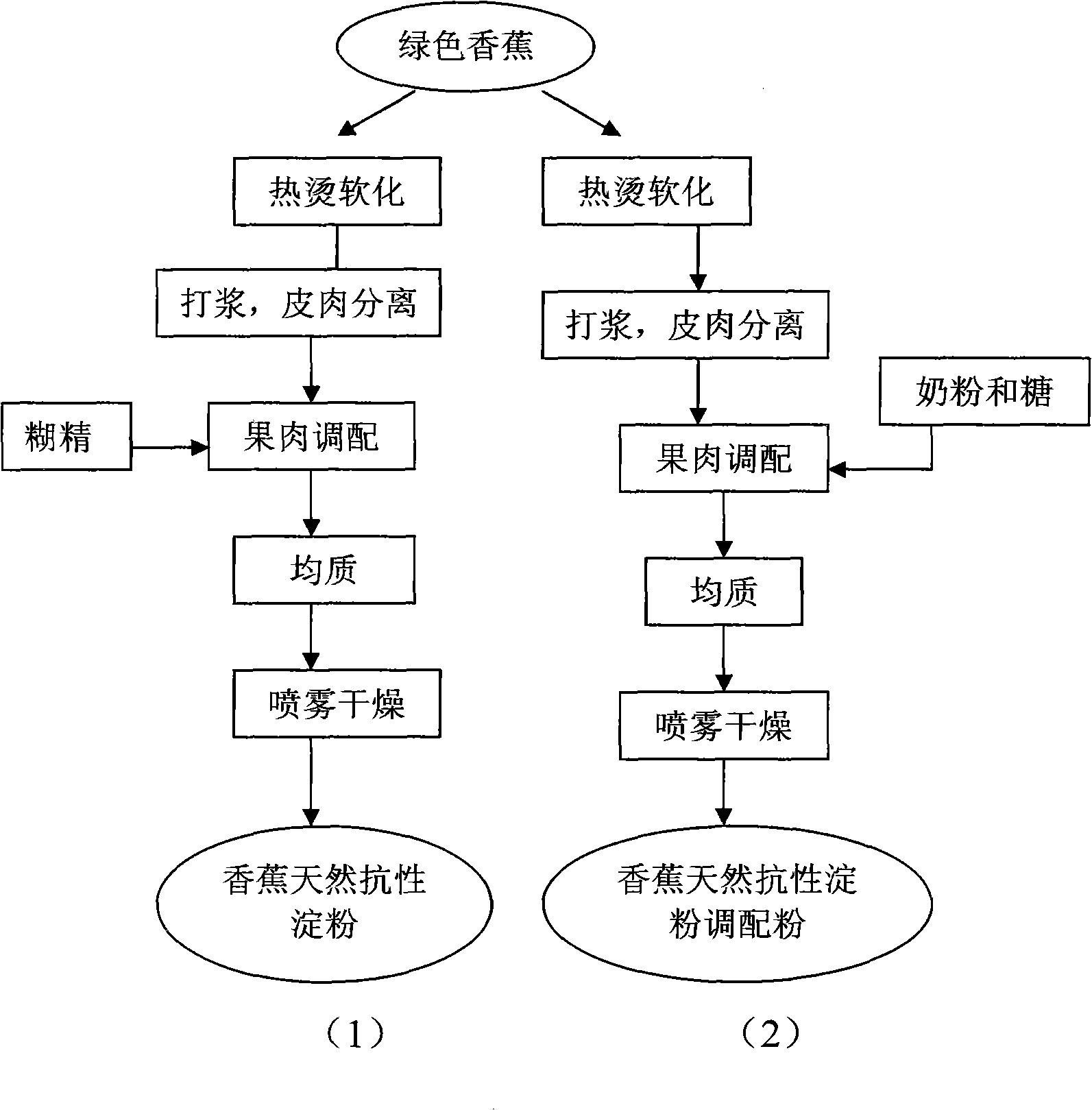

[0035] as attached figure 1 The technical route (1) shown in the specific operation is as follows:

[0036] (1) Banana raw material processing: choose fruit with green peel, plump fruit or banana defective fruit, non-commercial banana, etc. It is better to choose bananas with lower maturity according to common sense; remove bananas with diseases, insect pests and rot, and use drinking water cleaning surfaces;

[0037] (2) Prepare a mixed solution of sodium bisulfite with a concentration of 1‰ and citric acid with a concentration of 4‰, add it to the processed banana raw material, boil and blanch the banana raw material for 2 to 3 minutes to soften it, sodium bisulfite and The mixing ratio of citric acid is with reference to the ratio of routine use in this technical field, and the preferred ratio of the two in the present invention is 1: 8; The mixed solution consumption and banana pulp weight...

Embodiment 2

[0043] Example 2 Preparation of Banana Natural Resistant Starch Finished Product

[0044] as attached figure 1 The technical route (1) shown in the specific operation is as follows:

[0045] (1) Banana raw material processing: choose fruit with green peel, plump fruit or banana defective fruit, non-commercial banana, etc. It is better to choose bananas with lower maturity according to common sense; remove bananas with diseases, insect pests and rot, and use drinking water cleaning surfaces;

[0046] (2) Prepare a mixed solution of sodium bisulfite with a concentration of 1‰ and citric acid with a concentration of 2‰, add it to the processed banana raw material, boil and blanch the banana raw material for 2 to 3 minutes to soften it, sodium bisulfite and The mixing ratio of citric acid is with reference to the ratio of routine use in this technical field, and the preferred ratio of the two in the present invention is 1: 8; The mixed solution consumption and banana pulp weight...

Embodiment 3

[0052] Example 3 Preparation of Banana Natural Resistant Starch Mixed Powder Finished Product

[0053] as attached figure 1 Technical route (2) shown in, step (1) to step (3) are the same as embodiment 1.

[0054] Step (4) After beating and separating the skin and flesh, add milk powder and sugar in the ratio of banana pulp: milk powder: sugar = 2: 2: 1 (w / w / w) to prepare a direct edible food that integrates nutrition and health care functions. All in one instant banana mix. Other steps are the same as those in Example 1. An instant banana resistant starch compound powder that can be directly eaten and integrates nutrition and health care functions can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com