Method for fermentation co-production of PDO,BDO and PHP by constructing gene engineering strain

A technology of genetically engineered bacteria and BDO, applied in the directions of microorganism-based methods, methods using microorganisms, biochemical equipment and methods, etc., can solve problems such as non-detection, and achieve added value, simple extraction process, and improved raw material utilization. rate effect

Active Publication Date: 2008-11-19

TSINGHUA UNIV +1

View PDF1 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Under anaerobic conditions, 5g / L glucose was used as the carbon source, and the medium supplemented with vitamin B12 was also fermented, but no PDO was detected in the fermentation broth after 48 hours of cultivation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

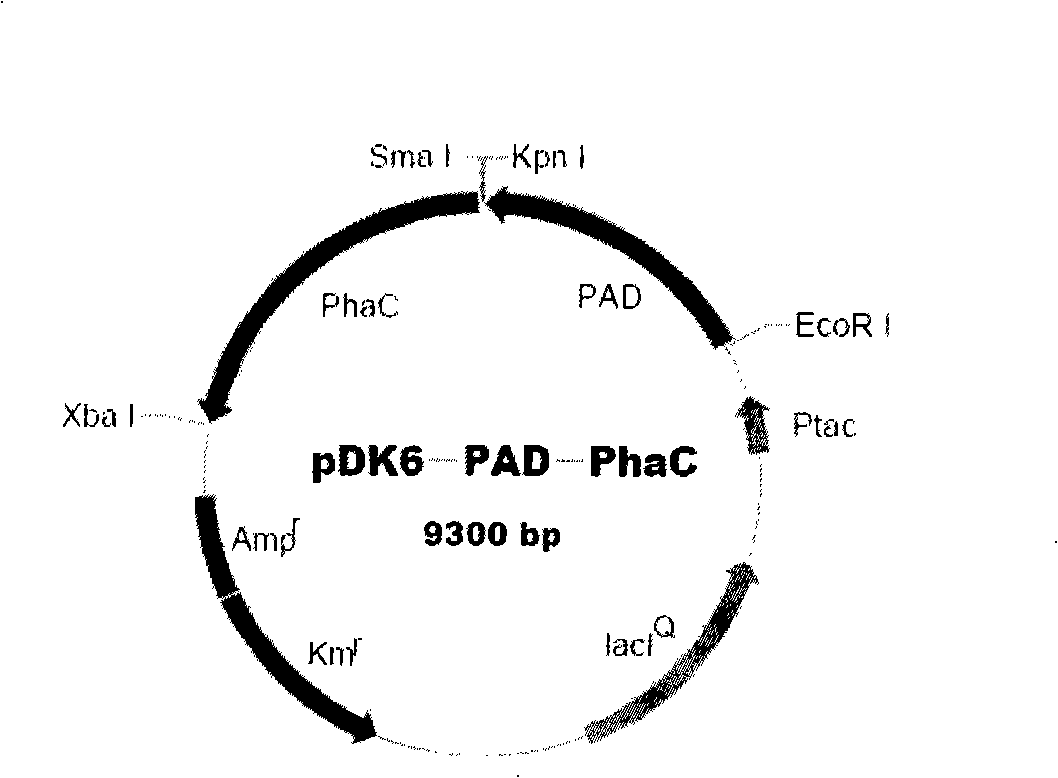

[0048] (1) Knockout of D-type lactate dehydrogenase gene

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

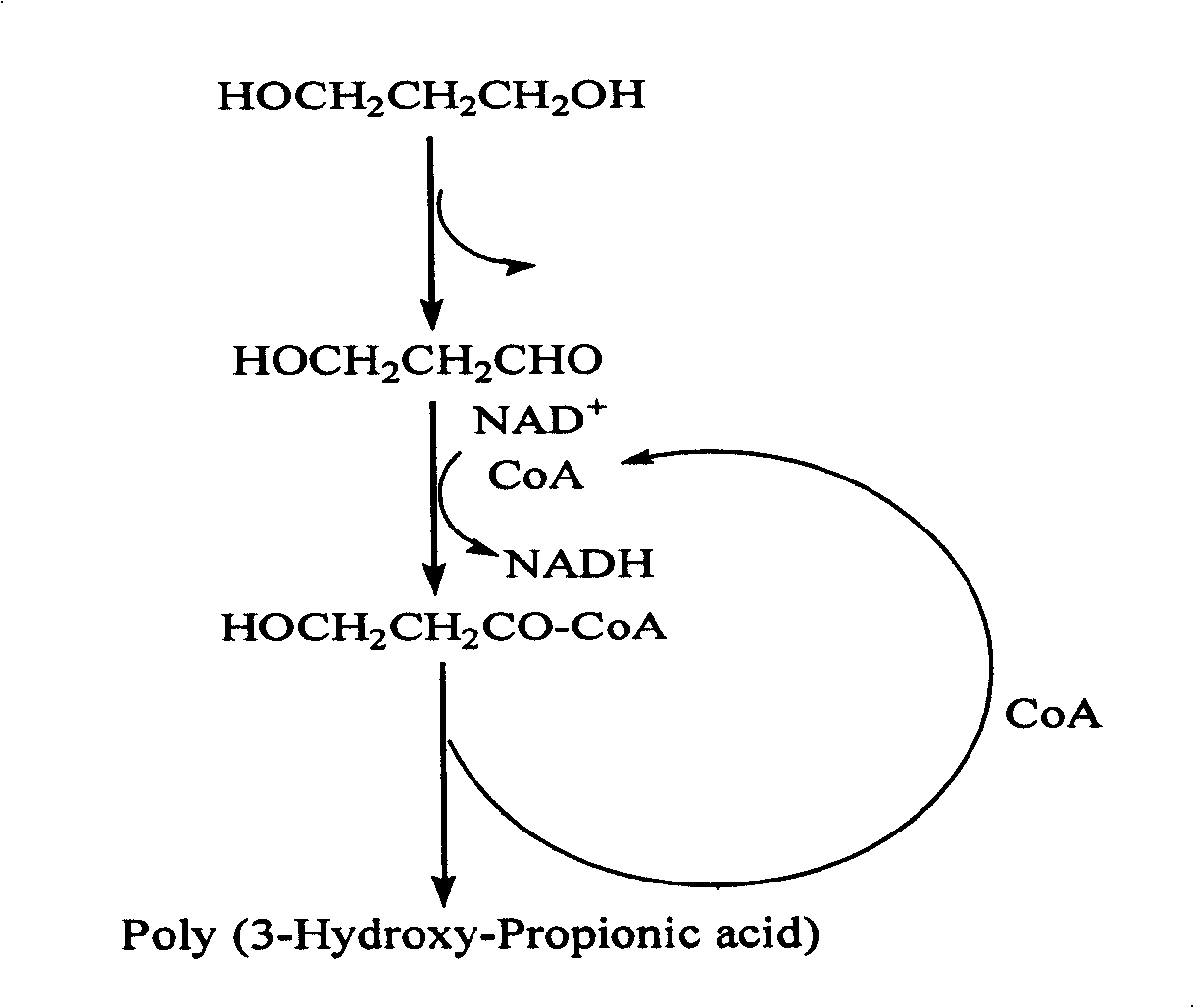

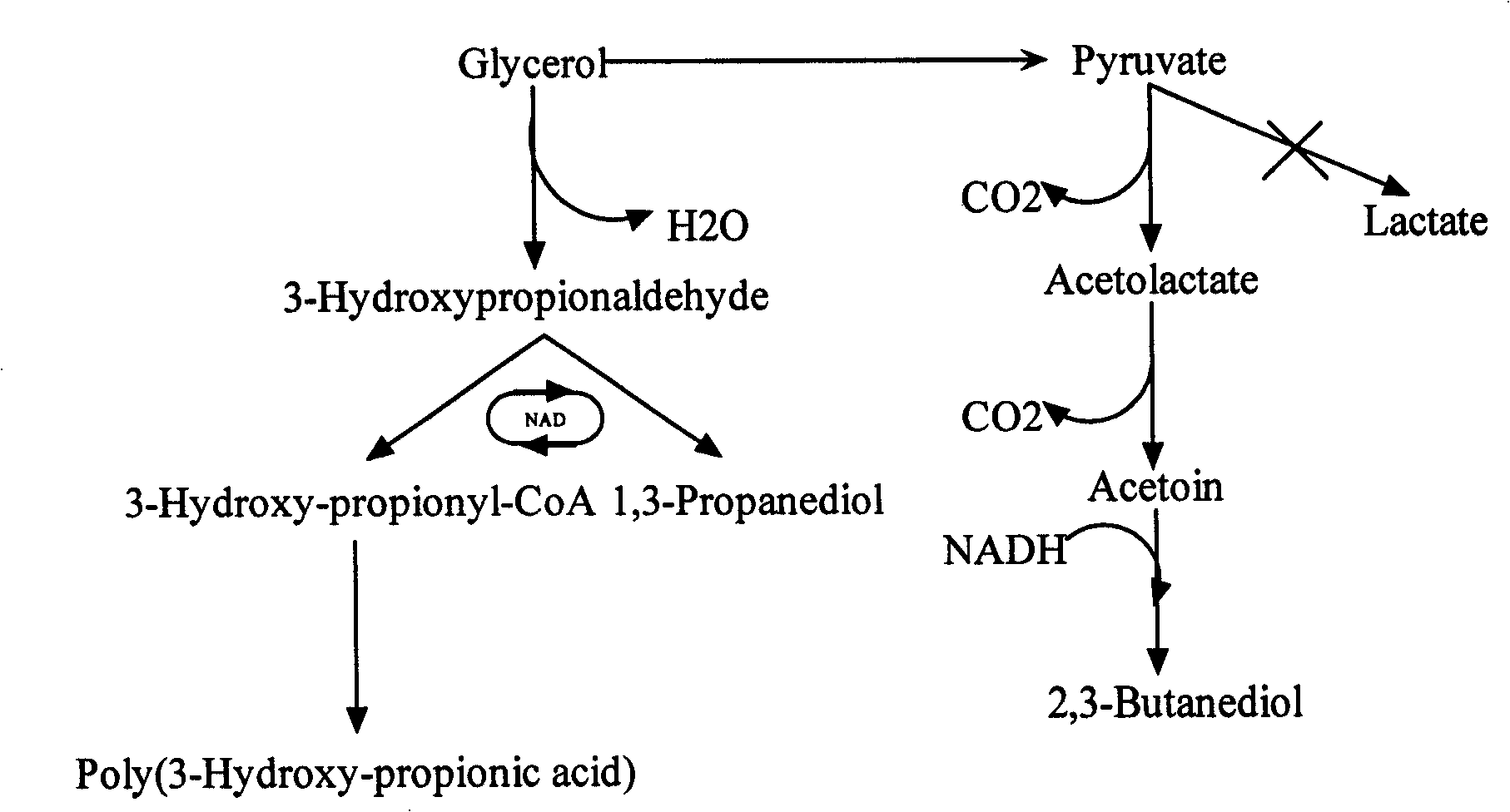

A method for constructing genetic engineering bacteria used in the fermentation and the coproduction of PDO, BDO and PHP belongs to the biochemical technical field. The process of the method comprises the following steps that: D-type lactate dehydrogenase gene is removed from wild fungus used for generating PDO, and coenzyme A dependent aldehyde dehydrogenase and polyhydroxy fatty acid synthase gene are introduced so as to construct genetic engineering bacteria used in the fermentation and the coproduction of PDO, BDO and PHP; aerobic fermentation and a fermentation adjust and control mode according to which glycerol and an alkali solution undergo mixing fed batch are adopted; and a product extraction flow during which fermentation broth undergoes membrane filtration, electrodialysis, concentration and rectification steps so as to separate the products of PDO, BDO and PHP. The method has the advantages that: the constructed genetic engineering bacteria can produce PDO, BDO and PHP at the same time, thereby increasing the utilization rate of raw materials and reducing production cost; meanwhile, the synthesis of byproduct lactic acid is reduced, and an after-extraction process is simplified so as to reduce extraction cost; moreover, the method increases the synthesis of thalli NADH2 while introducing PHP.

Description

technical field [0001] The invention belongs to the field of biochemical technology, and in particular provides a method for constructing genetically engineered bacteria to ferment and co-produce PDO, BDO and PHP; the PDO is the abbreviation of 1,3-propanediol, and the abbreviation of BDO is 2,3-butanediol , PHP is a polymer (poly-β-hydroxypropionic acid) produced by the polymerization of β-hydroxypropionic acid as a monomer. Background technique [0002] 1,3-Propanediol (PDO for short) is an important chemical raw material, which can be used as an organic solvent in ink, printing and dyeing, paint, lubricant, antifreeze and other industries. The main use of PDO is as a monomer for the synthesis of polyester and polyurethane, especially polytrimethylene terephthalate (PTT) produced by polymerization with terephthalic acid, which shows a higher ratio than 1,2-propanediol and butanediol Polymers synthesized from alcohols and ethylene glycol as monomers have better performance...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12P7/18C12P7/64C12N1/21C12R1/22C12R1/01

CPCC12P7/18C12N1/32C12N9/0006C12N9/0008C12N9/1029C12P7/42C12P7/625Y02E50/13Y02E50/10

Inventor 刘德华刘宏娟欧先金孙燕许赟珍雷跃勇刘卫斌

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com