Method for producing photocurable liquid resin and photocurable liquid resin produced by such method

A light-curable, liquid resin technology, applied in chemical instruments and methods, other chemical processes, engine sealing, etc., can solve the problems of unstretched tensile strength, lack of practicability, low molecular weight, etc., and achieve heat resistance Excellent, high water vapor barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

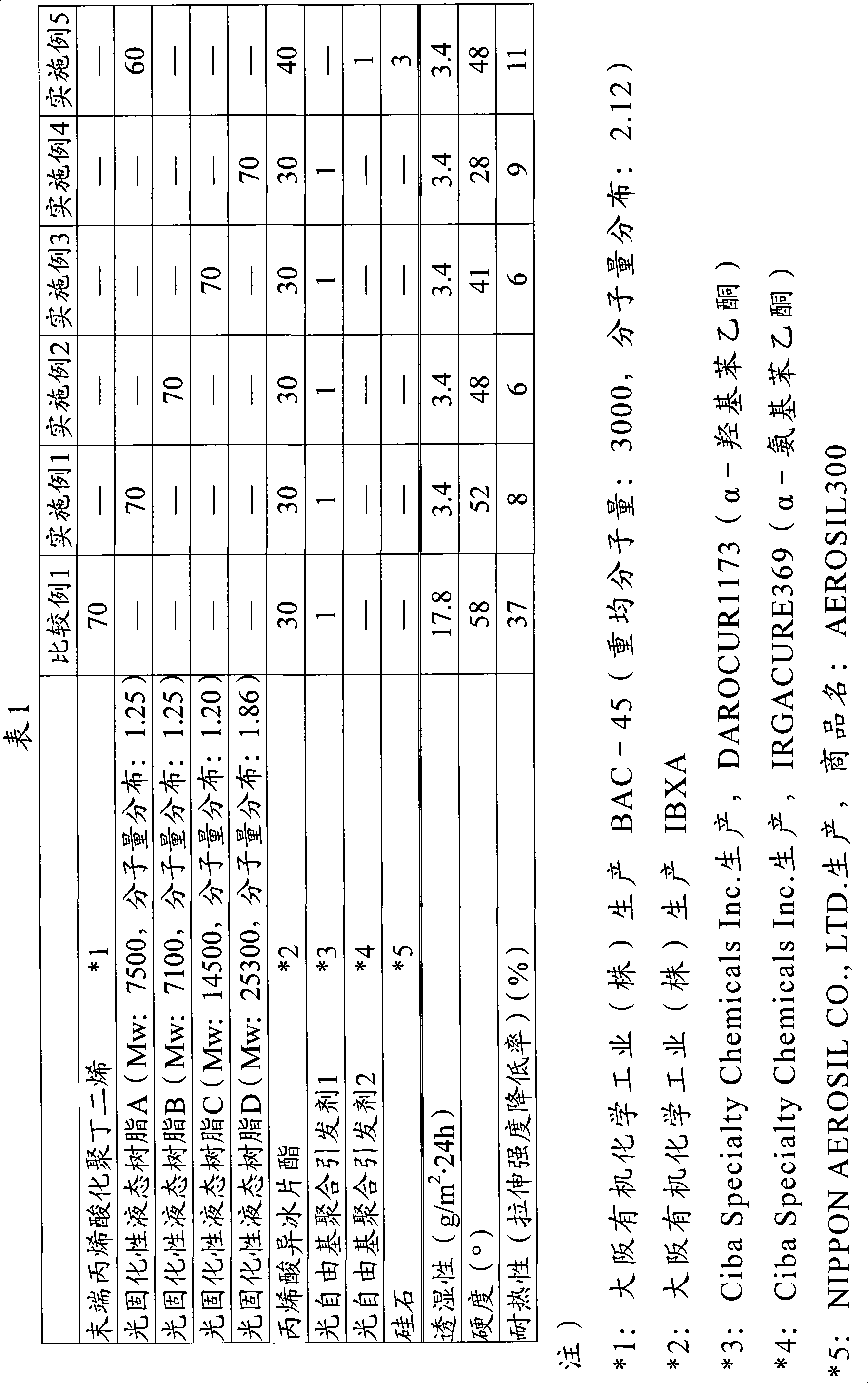

[0071] Next, the present invention will be described in further detail through examples, but the present invention is not limited to these examples at all.

[0072] In addition, the weight average molecular weight, moisture permeability, hardness, and heat resistance were measured according to the following methods.

[0073] (1) Weight average molecular weight

[0074] The GPC method (Gel Permeation Chromatography) was used to obtain the weight average molecular weight in terms of polystyrene.

[0075] (2) Water permeability

[0076] Using a moisture-permeable cup of Method A described in JIS L1099, it is measured under the conditions of 40°C and 90% relative humidity based on JIS Z0208. As the test body, a sheet with a thickness of 0.86 mm was used.

[0077] (3) Hardness

[0078] Based on JIS K6253, the hardness of the cured product was measured with a type A durometer. As a test body, 7 sheets with a thickness of about 0.9 mm were laminated to a sheet with a thickness of about 6...

manufacture example 1

[0082]In the fully dehydrated and purified cyclohexane solvent, add 1 mol of 1,3-(diisopropenyl) benzene, and then sequentially add 2 mol of triethylamine and 2 mol of sec-butyl lithium, and stir at 50°C for 2 hours to prepare a double Lithium polymerization initiator.

[0083] Into a 7L polymerization reactor replaced with argon, 1.35kg of dehydrated and purified cyclohexane, 2.67kg of 22.9% by mass 1,3-butadiene monomer in hexane solution, and 209.4ml of 1.6mol / L OOPS ( A hexane solution of 2,2-bis(tetrahydrofuryl)propane), and then 223.5 ml of a 0.5 mol / L dilithium polymerization initiator was added to start polymerization.

[0084] While raising the temperature of the polymerization reactor to 50° C., polymerization was carried out for 1.5 hours, and then 220.4 ml of a 1 mol / L ethylene oxide cyclohexane solution was added, stirred for a further 2 hours, and then 50 ml of isopropanol was added. The hexane solution of the polymer was precipitated in isopropanol and dried suffici...

manufacture example 2

[0086] Into a 7L polymerization reactor replaced with argon, 1.50 kg of dehydrated and purified cyclohexane, 2.00 kg of 22.9 mass% 1,3-butadiene monomer hexane solution, and 0.765 kg of 20.0 mass% styrene monomer were added. 209.4ml 1.6mol / LOOPS hexane solution, and then add 223.5ml 0.5mol / L dilithium polymerization initiator.

[0087] While raising the temperature of the polymerization reactor to 50° C., polymerization was carried out for 1.5 hours, and then 220.4 ml of a 1 mol / L ethylene oxide cyclohexane solution was added, stirred for a further 2 hours, and then 50 ml of isopropanol was added. The hexane solution of the polymer was precipitated in isopropanol and dried sufficiently to obtain a polymer polyol B. The polymer polyol B is a two-terminal OH group styrene-butadiene copolymer, the styrene part is 25% by mass, the weight average molecular weight is 7,100, and the molecular weight distribution is 1.25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com