Method for preparing precipitated silica with boron sludge

A technology for precipitating silicon dioxide and silicon dioxide, applied in the directions of silicon dioxide, silicon oxide, magnesium carbonate, etc., can solve the problems of unutilized silicon, consumption of large sulfuric acid, and high production cost, so as to improve the comprehensive utilization rate of resources, Effects of addressing environmental impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

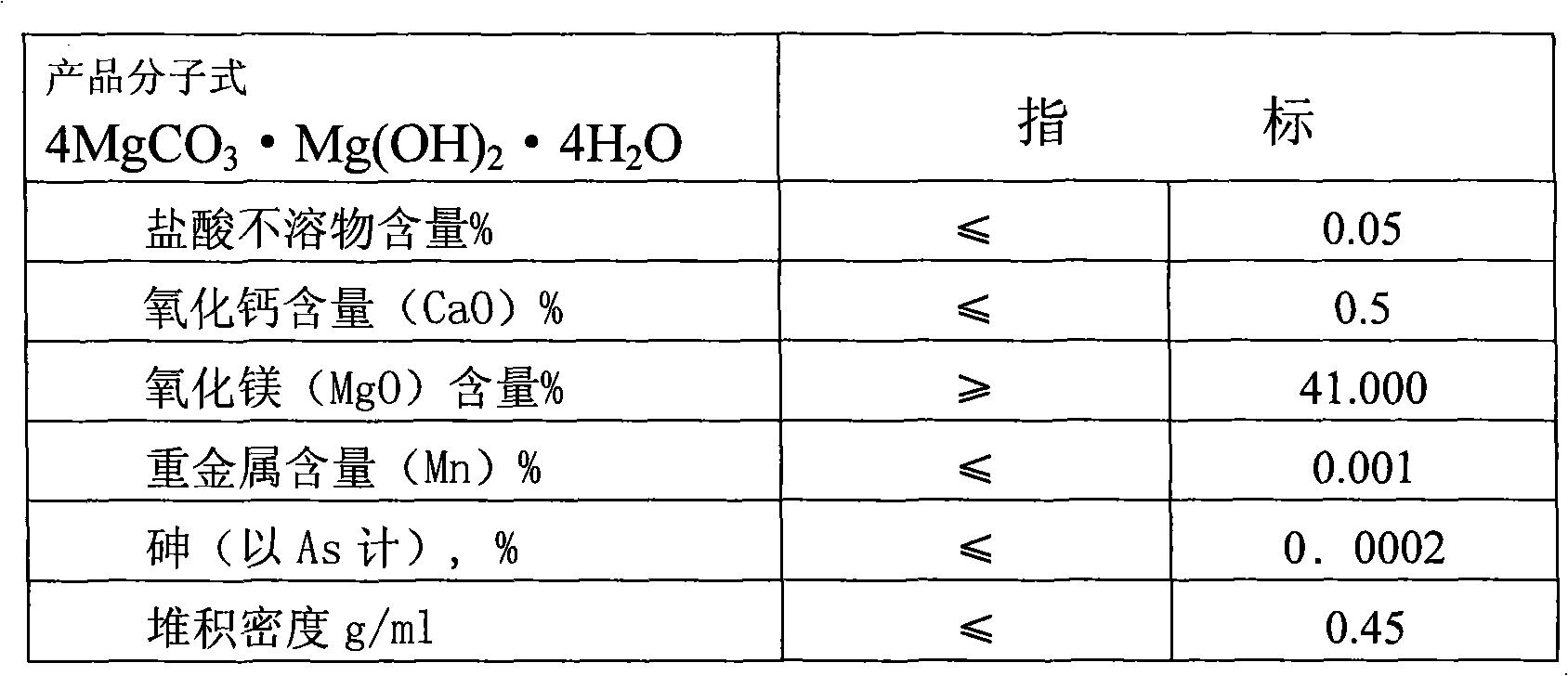

[0025] Embodiment 1: preparation of food grade magnesium carbonate by acid leaching boron mud

[0026] raw material:

[0027] A. Boron mud: the main component is MgO 33wt%; SiO 2 22wt%;

[0028] B. Sulfuric acid: industrial grade, concentration 93%;

[0029] Activator: hydrofluoric acid.

[0030] Acid leaching: Mix the undried wet-based boron mud with water at a solid-to-liquid ratio of 1:1 for beating, first add 2% activator, stir well, then add the calculated amount of sulfuric acid, and react at about 90°C for 30 minutes. When the slurry thickens, add water to dilute it, control the solid-liquid ratio of 3:1, and react at about 90°C for 90 minutes. When the pH value is stable at about 7.5, add oxidant hydrogen peroxide or sodium hypochlorite and react for 10 minutes, then add Add additives (light-burned magnesia or bitter earth powder) to adjust the pH value, and then heat and react at 90°C for 30 minutes. At this time, impurities such as iron and aluminum are almost c...

Embodiment 2

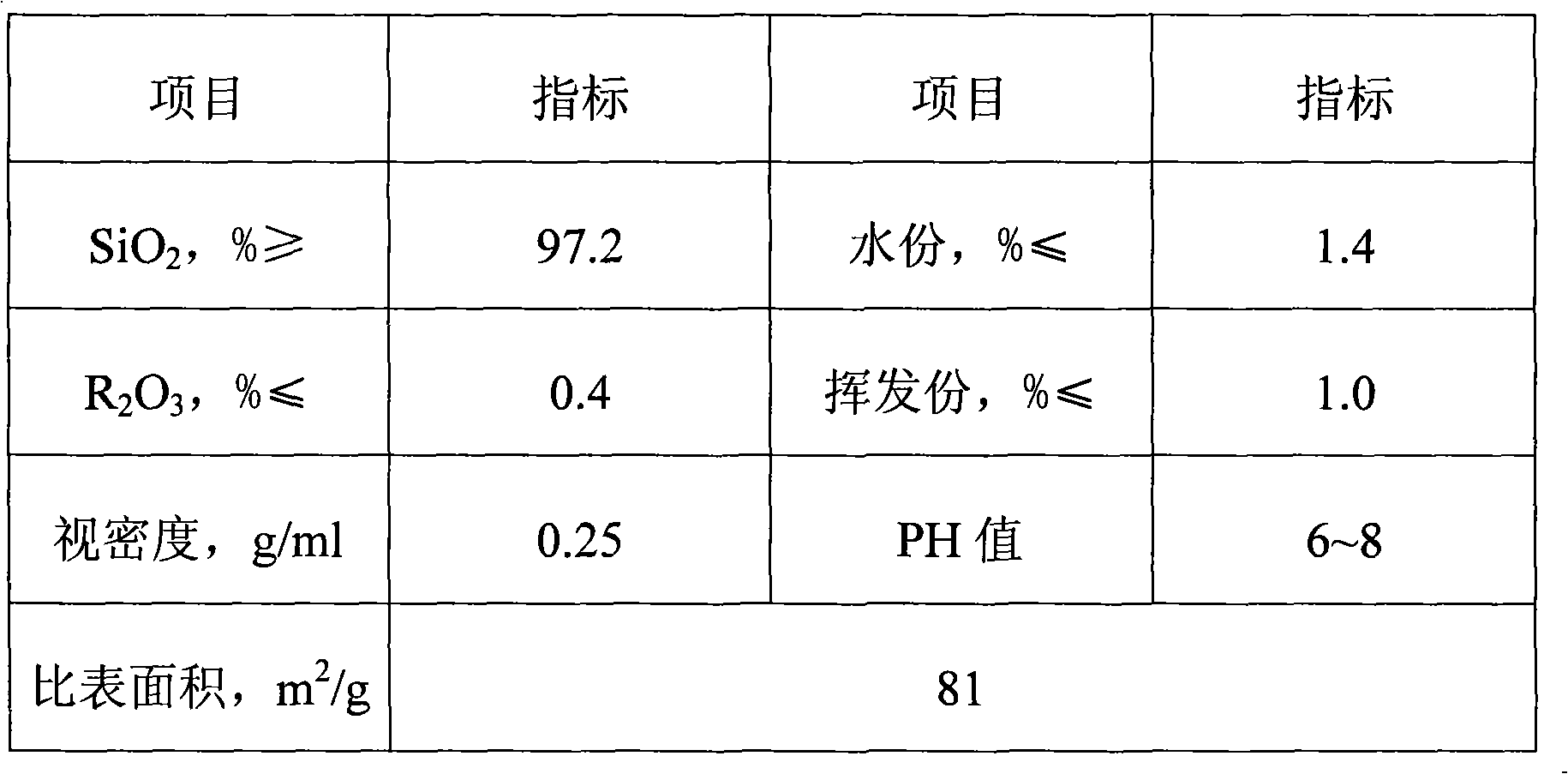

[0060] Embodiment 2: Secondary boron mud prepares precipitated silica

[0061] (1) Mix the secondary boron mud and tap water at a ratio of 0.3:1 for beating, filter, and repeat four times. And silicon tetrafluoride (SiF 4 ) Volatility method to determine the silica content.

[0062] (2), dilute the liquid lye to about 12%.

[0063] (3) Washing the secondary boron mud (mainly composed of active silicon dioxide) obtained after acidolysis and filtration to contain sulfate ≤ 0.5%. Then use a sodium hydroxide solution with a concentration of 12%, and mix according to 115% of the theoretical amount, soak and dissolve for 120 minutes under the condition of 95-100°C, so that the silicon dioxide in the boron mud is converted into sodium silicate, and obtained by filtration. Liquid Sodium Silicate. The resulting residue was filtered and discarded.

[0064] Chemical reaction: 2NaOH+SiO 2 →Na 2 SiO 3 +H 2 o

[0065] Determination of SiO in waste residue by silicon tetrafluoride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com