Electrolytic solution for preparing nano ceramic coatings by micro-arc oxidation

A technology of micro-arc oxidation and nano-ceramics, which is applied in the field of electrolyte, can solve the problems of high surface roughness of the coating, which affects the promotion and application of ceramic coatings, etc., and achieves the effect of cheap raw materials, uniform microhardness distribution, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

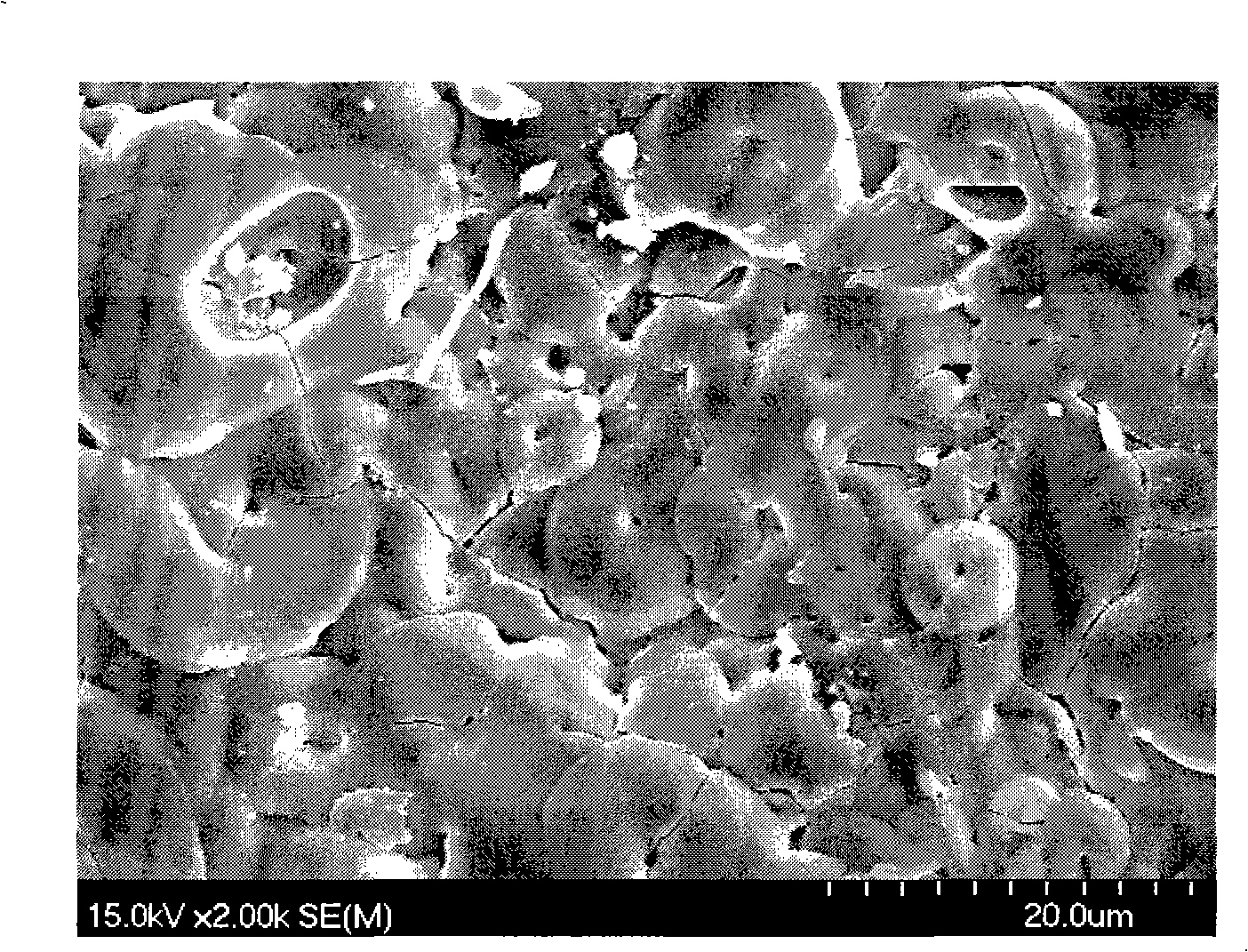

[0065] A 20kW DC pulsed micro-arc oxidation device is used to carry out micro-arc oxidation on the surface of aluminum alloy. The equipment is composed of a micro-arc oxidation power supply, an electrolytic tank, a stirring system and a cooling system. The micro-arc oxidation process is: sanding, degreasing, deionized water, rinsing, micro-arc oxidation, tap water rinsing, natural drying, the electrolyte is an analytically pure aqueous solution, the sample is used as an anode and immersed in the treatment solution, with a cooling system The stainless steel container is used as the cathode, and the power supply is operated in a constant current mode, and the micro-arc oxidation time is 30-90min.

[0066] Raw material preparation: Al 2 o 3 Nano powder (particle size 10~50nm) 2g, Na 2 B 4 o 7 10H 2 O 75.8g, distilled water 4L, LD31 aluminum alloy substrate.

[0067] Material preparation: According to the above composition, Na 2 B 4 o 7 10H 2 O dissolved in distilled wat...

Embodiment 2

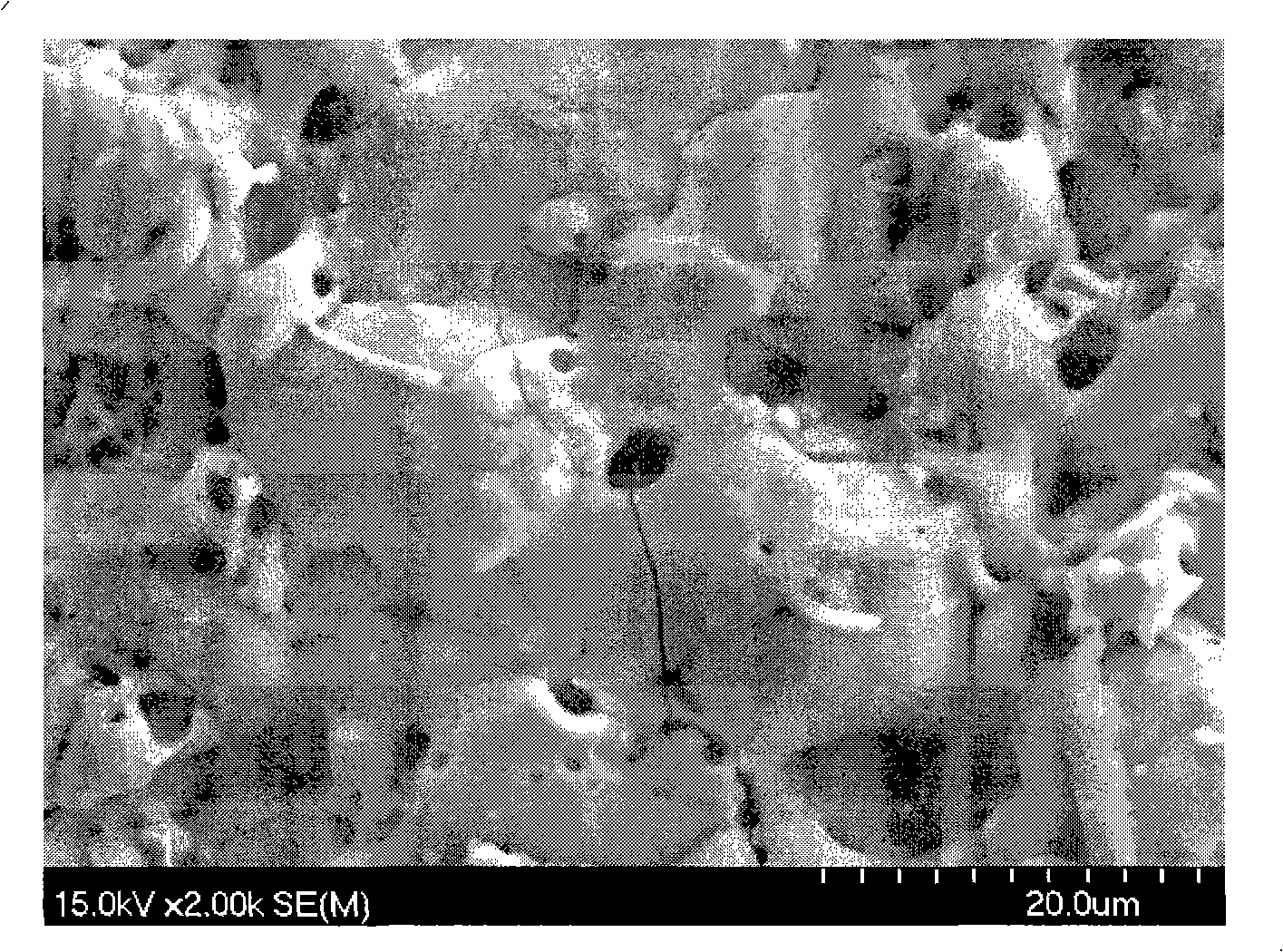

[0069] Raw material preparation: Al 2 o 3 Nano powder (particle size 10~50nm) 4g, Na 2 B 4 o 7 10H 2 O 151.6g, distilled water 4L, LY12 aluminum alloy substrate.

[0070] Material preparation: According to the above composition, Na 2 B 4 o 7 10H 2 O dissolved in distilled water, Al 2 o 3 The nanopowder is poured into the bath and stirred. The micro-arc oxidation process adopts a constant current method, and the current density is 18A / dm 2 , the micro-arc oxidation time is 60min, and others are the same as in Example 1. The surface of the obtained nano-ceramic coating is smooth and the roughness is small.

Embodiment 3

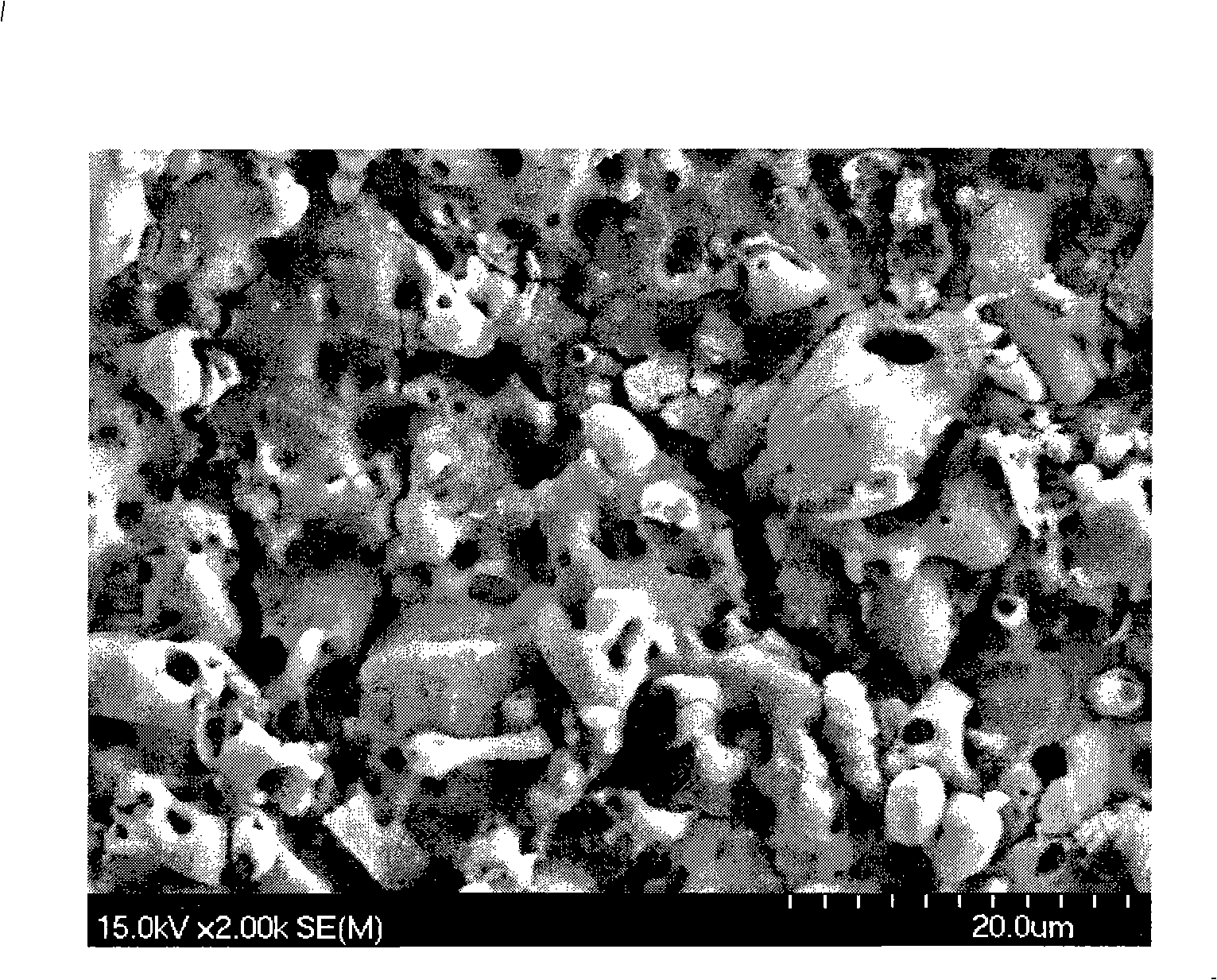

[0072] Raw material preparation: Al 2 o 3 Nano powder (particle size 10~50nm) 2g, NaAlO 2 60g, distilled water 4l, LD31 aluminum alloy substrate.

[0073] Material preparation: According to the above composition, NaAlO 2 Dissolved in distilled water, the Al 2 o 3 The nanopowder is poured into the bath and stirred. The micro-arc oxidation process adopts a constant current method, and the current density is 15A / dm 2 , the micro-arc oxidation time is 60min, and others are the same as in Example 1. The surface of the obtained nano-ceramic coating is smooth and the roughness is small, and its scanning electron microscope photo is shown in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com