Light anode for dye sensitization solar battery and preparation method thereof

A technology for solar cells and dye sensitization, which is applied in the field of photoanode of dye-sensitized solar cells and its preparation, can solve the problems of short lifespan of excited states, influence energy transmission efficiency, etc. The effect of reducing electron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

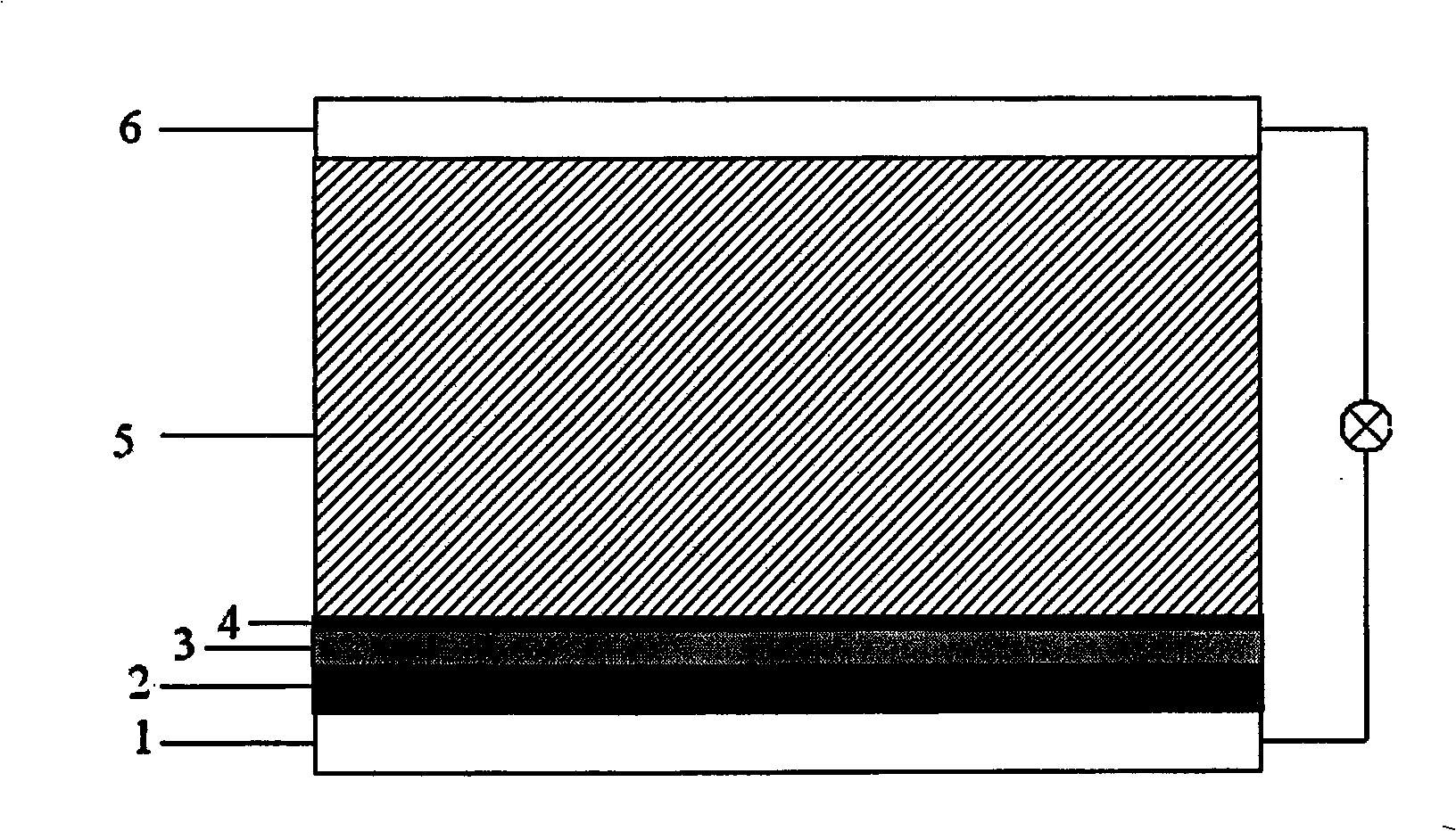

Image

Examples

Embodiment 1

[0017] TiO with a particle size of 2 nm and a thickness of 50 μm 2 Put the porous film into a mixed solution of tetraethyl orthosilicate and cyclohexane with a volume ratio of 1:50, add 10 drops of surfactant NP-40 (nonylphenol polyoxyethylene ether), mix well and soak for 20 minutes , add ammonia water according to 70% of the volume of ethyl orthosilicate, soak at room temperature for 12 hours, add silane coupling agent KH550 (γ-aminopropyltriethoxysilane) according to 70% of the volume of ethyl orthosilicate, and then react 12 hours, then washed with acetone, and dried in a drying oven at 80°C for 30 minutes. The modified TiO 2 Nanoporous film at 3.5×10 -3 After soaking in mol / L N3 ethanol solution for 12 hours, take it out and dry it in the air, use iodine / lithium iodide electrolyte, platinum-plated conductive glass as the counter electrode, and assemble it into a battery. The transparent conductive glass may be indium-doped tin dioxide glass or fluorine-doped tin dioxid...

Embodiment 2

[0019] The particle size is 100nm, and the ZnO porous film with a thickness of 1 μm is put into a mixed solution of tetraethyl orthosilicate and cyclohexane with a volume ratio of 1:10, and 2 drops of surfactant NP-40 (nonylphenol polyoxyethylene ether), mix well and soak for 60 minutes, add ammonia water according to 40% of the volume of tetraethyl orthosilicate, soak at room temperature for 6 hours, add silane coupling agent KH550 (γ-aminopropyl Triethoxysilane), reacted for another 24 hours, then washed with acetone, and dried in a drying oven at 80°C for 30 minutes. The modified ZnO nanoporous film was placed at 3.5×10 -5 After soaking in mol / L N3 ethanol solution for 1 hour, take it out and dry it in the air, use iodine / lithium iodide electrolyte, platinum-plated conductive glass as the counter electrode, and assemble it into a battery.

Embodiment 3

[0021] TiO with a particle size of 50 nm and a thickness of 30 μm 2 Put the porous film into a mixed solution of tetraethyl orthosilicate and cyclohexane with a volume ratio of 1:30, add 5 drops of surfactant, mix well, soak for 30 minutes, and add 50% of the volume of tetraethyl orthosilicate Ammonia, soak at room temperature for 10 hours, add silane coupling agent KH550 (γ-aminopropyltriethoxysilane) according to 60% of the volume of tetraethoxysilane, react for another 20 hours, then wash with acetone, and place in a dry box Dry at 80°C for 30 minutes. Modified TiO 2 Porous film at 3.5 x 10 -4 After soaking in the organic solution of mol / L dye for 6 hours, take it out and dry it in the air, use iodine / lithium iodide electrolyte, and platinum-plated conductive glass as the counter electrode, and assemble it into a battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com