Method for quickly and massively separating high purity triptolide from thunder god vine

A technology of triptolide and triptolide, which is applied in the field of rapid large-scale separation of high-purity triptolide, and achieves the effect of simple process, easy control and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for rapidly and massively separating high-purity triptolide from Tripterygium wilfordii is characterized in that it is carried out according to the following process steps:

[0035] A. Heating extraction: select 30kg of tripterygium wilfordii stem and leaf coarse powder with a particle size of 10 mesh, add methanol at a mass ratio of 1:5, heat at 50°C for 3 hours, remove slag by filtration, recover the filtrate under reduced pressure to remove methanol, and obtain water suspension;

[0036] B. Solvent extraction: Take 10 L of the aqueous suspension obtained in step A, first extract with 20 L of petroleum ether, and then extract the aqueous phase with 30 L of dichloromethane, each extraction 3 times. The petroleum ether layer was discarded after recovery of petroleum ether, and the dichloromethane extracts were combined and concentrated at 50°C to obtain 150 g of dark yellow precipitate (density 1.26).

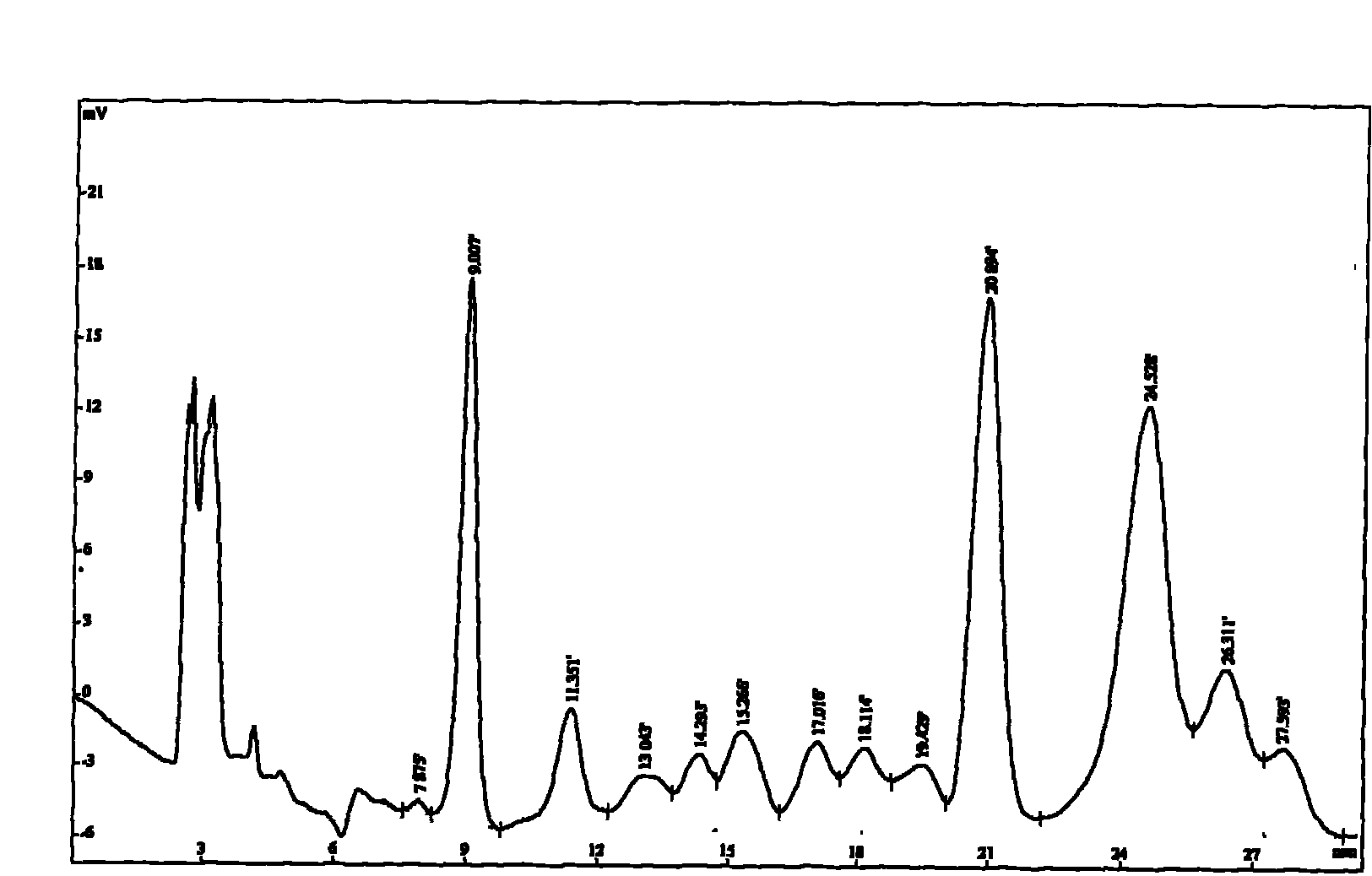

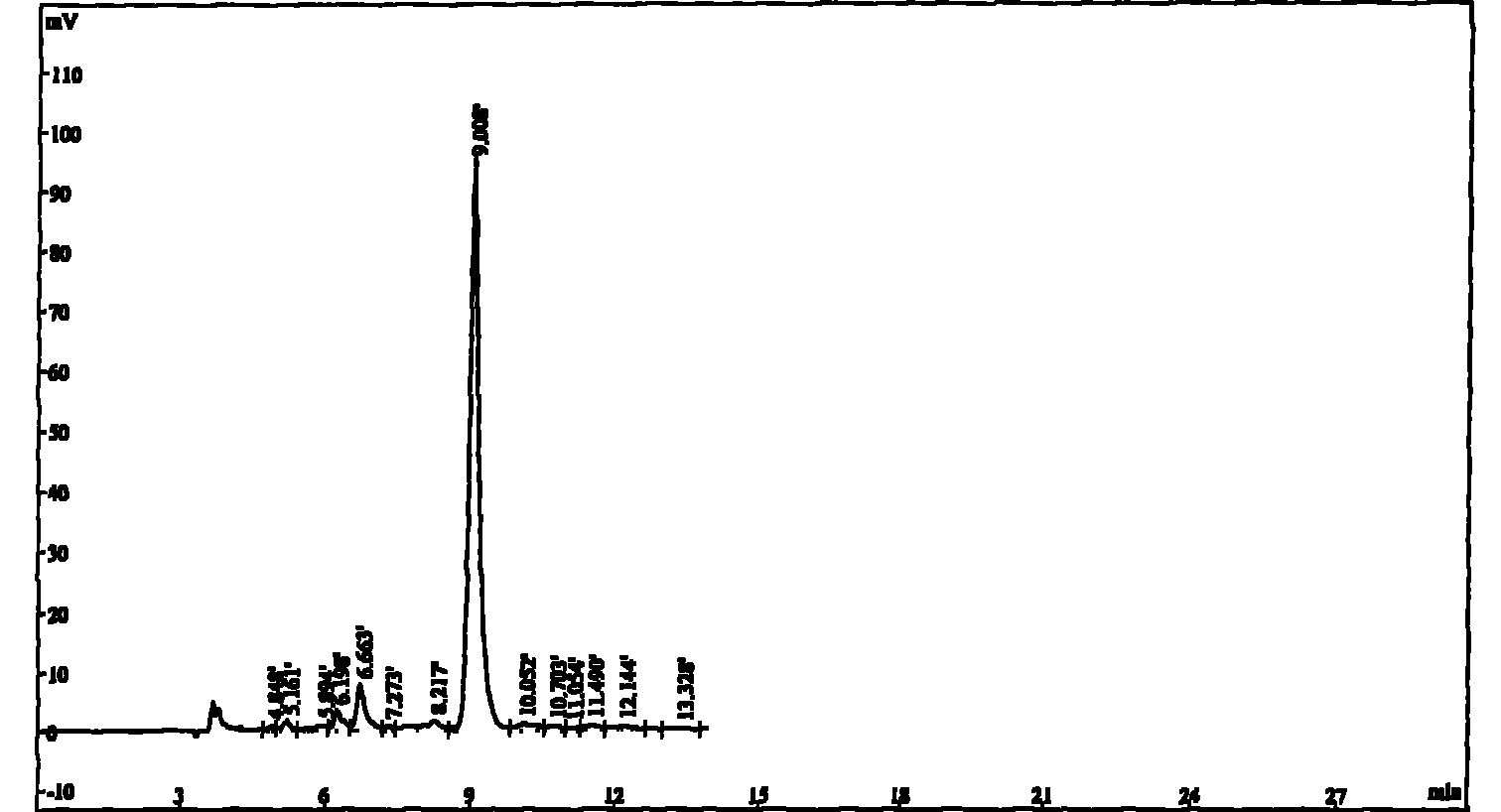

[0037] C. Chromatographic column chromatography: take 20 ...

Embodiment 2

[0042] A method for rapidly and massively separating high-purity triptolide from Tripterygium wilfordii is characterized in that it is carried out according to the following process steps:

[0043] A. Heating extraction: Select 500kg of coarse powder of tripterygium wilfordii with a particle size of 20 mesh, add 95% ethanol at a mass ratio of 1:5, heat at 55°C for 3 hours, filter to remove slag, and recover the filtrate under reduced pressure to remove ethanol After that, an aqueous suspension is obtained;

[0044] B. Solvent extraction: Take 500 L of the aqueous suspension obtained in step A, first extract with 1000 L of petroleum ether, and then extract the aqueous phase with 1500 L of dichloromethane, each extraction 5 times. The petroleum ether layer was discarded after recovery of petroleum ether, and the dichloromethane extracts were combined and concentrated at 55°C to obtain 9000 g of dark yellow precipitate (density 1.26).

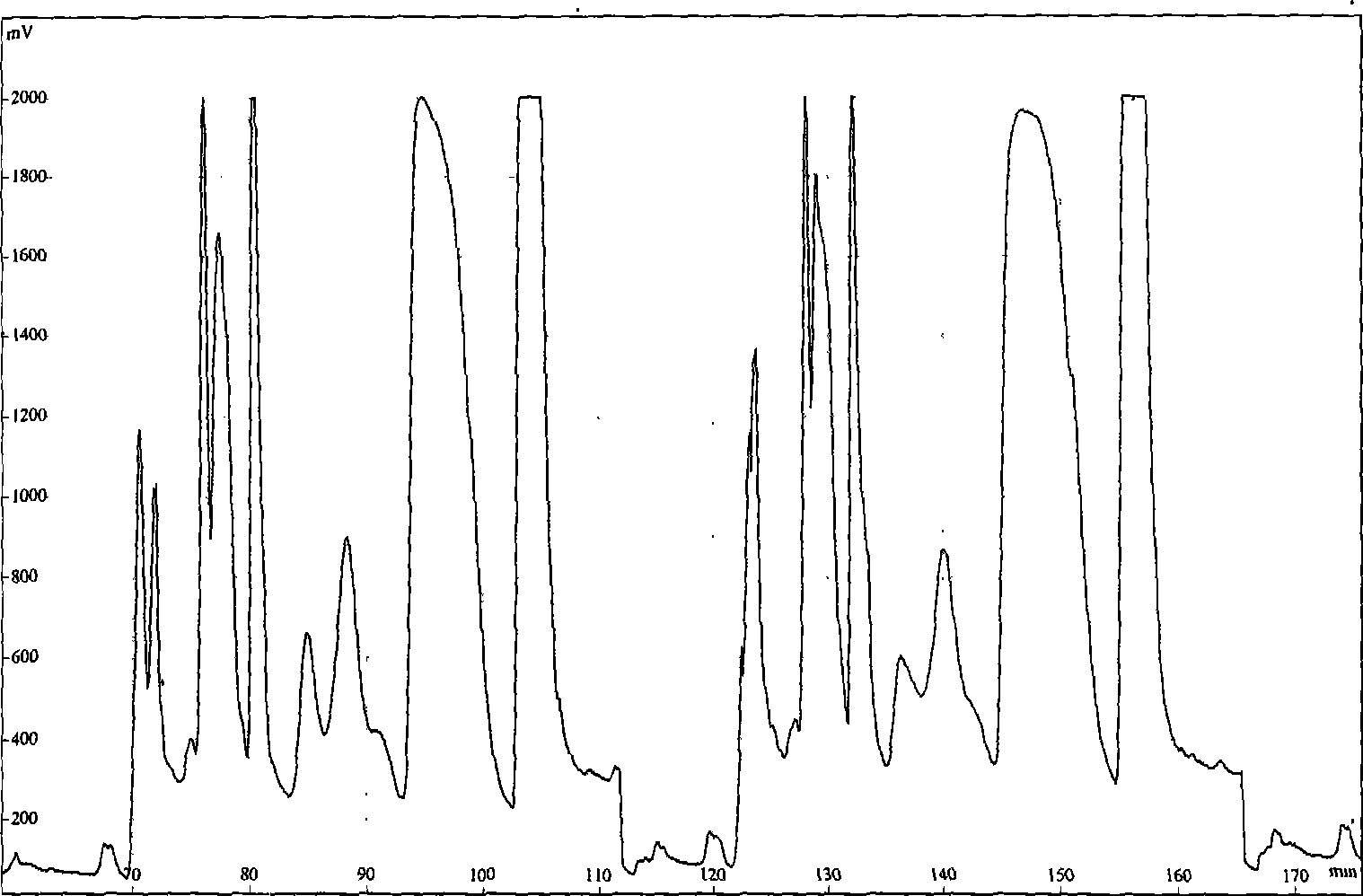

[0045] C. Chromatographic column chromatog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com